Method and device for applying layered and heterogeneous straw with different degrees of fragmentation and maturity to saline-alkali land

A technology of decomposing maturity and saline-alkali land, applied in land preparation methods, agricultural machinery and implements, agriculture, etc., can solve problems such as unsatisfactory effect and slow effect, and achieve the effect of reducing the rise of salt content, alleviating salinization, and having a wide range of sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

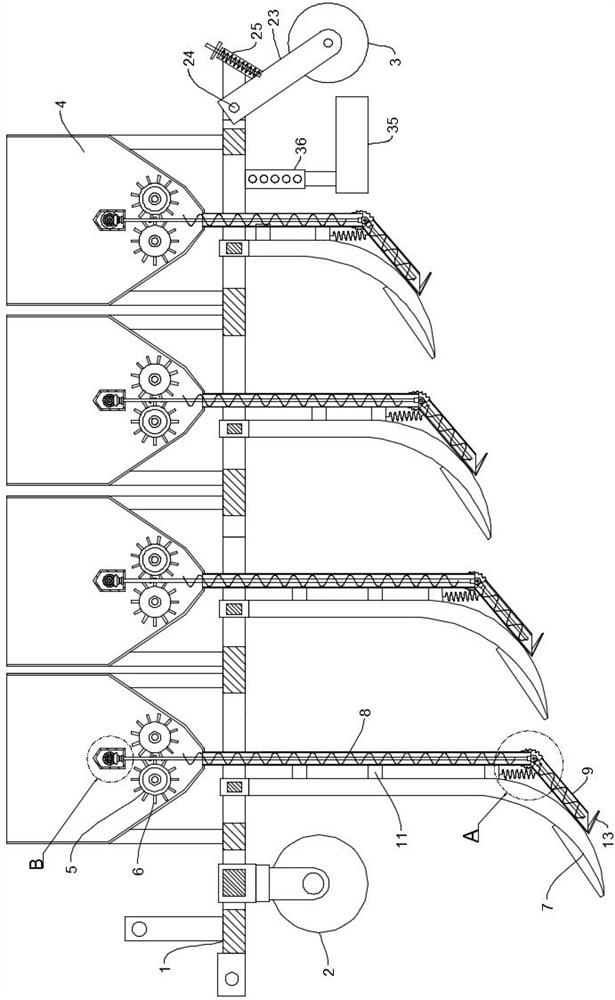

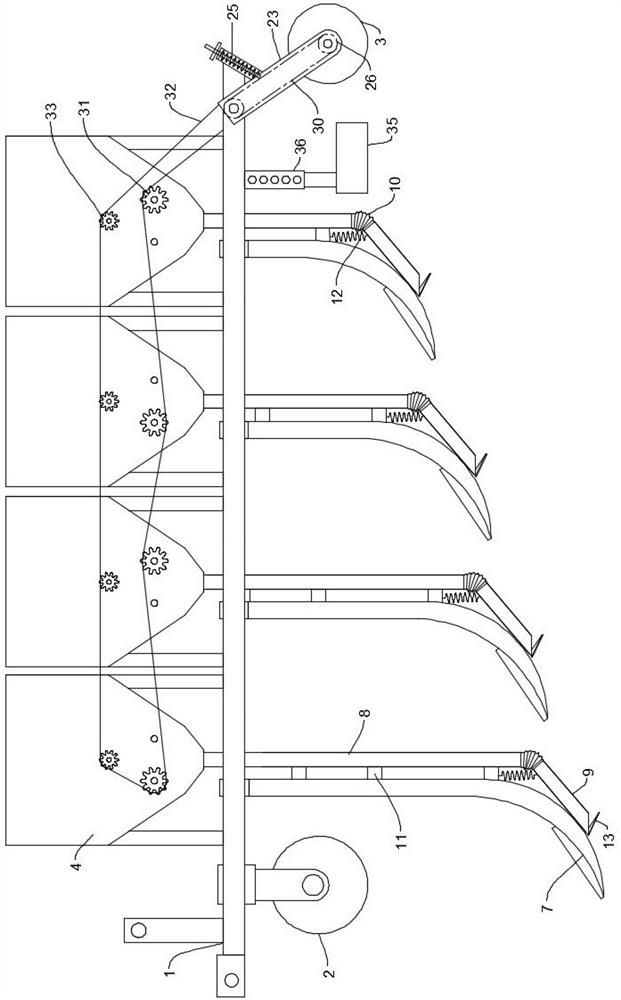

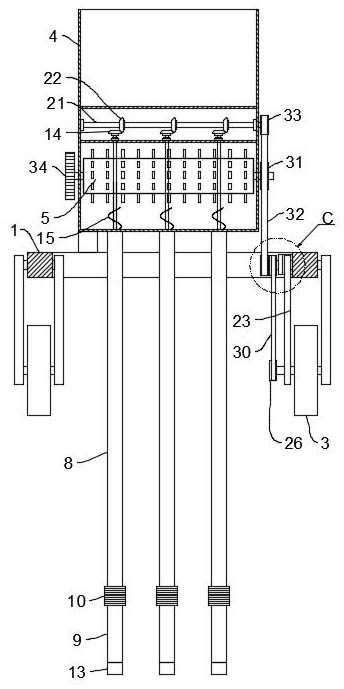

[0040] A method for ex-situ application of straws with different fragmentation and decomposing degrees into saline-alkali land in layers. First, the 0-40 cm soil layer of the saline-alkali land is equally divided into 0-10 cm soil layers and 10-20 cm soil layers according to 10 cm layers. , 20 ~ 30 cm soil layer and 30 ~ 40 cm soil layer four soil layers, 0 ~ 10 cm soil layer is applied with straw with a fragmentation of less than 3 cm, and this layer of soil is mixed with slow and controlled release fertilizer, 10 ~ 20 cm Straw with a fragmentation of about 3-5 cm is applied to the soil layer, and straw rot-promoting agent is added at the same time; straw with a fragmentation of about 5-8 cm is applied to the 20-30 cm soil layer, which can wash the upper layer of salt and excessive salt. The water is introduced into the plough layer; the 30-40 cm soil layer is applied with straw with a crushing degree of 8-12 cm, which is conducive to lateral drainage, and at the same time can...

Embodiment 2

[0055] First, the 0-40 cm soil layer of the saline-alkali land is divided into four soil layers, 0-10 cm soil layer, 10-20 cm soil layer, 20-30 cm soil layer and 30-40 cm soil layer, according to 10 cm layers. The 0 ~ 10 cm soil layer is applied with straw with a fragmentation of about 2 cm, and the soil layer is mixed with slow and controlled release fertilizer, and the 10 ~ 20 cm soil layer is applied with straw with a fragmentation of about 3 ~ 5 cm, and straw is added at the same time. Corrosion promoter; 20-30 cm soil layer is applied with straw with a crushing degree of about 5-8 cm; 30-40 cm soil layer is applied with straw with a crushing degree of about 10 cm, and the soil layers are applied from top to bottom. The maturity of straw gradually decreased.

[0056] Select a moderately saline-alkali soil experimental area, the total soil salt content is about 0.45%, and the pH value is 8.9-9.1. Through the above method, the straws of different fragmentation and decomposin...

Embodiment 3

[0061] A method for ex-situ application of straws with different fragmentation and decomposing degrees into saline-alkali land in layers. First, the soil layer of 0-40 cm of the saline-alkali land is equally divided into 0-10 cm soil layer and 10-20 cm soil layer according to 10 cm layer. , 20 ~ 30 cm soil layer and 30 ~ 40 cm soil layer four soil layers, 0 ~ 10 cm soil layer is applied with straw with a fragmentation of less than 3 cm, and at the same time, this layer of soil is mixed with slow and controlled release fertilizer, 10 ~ 20 cm The soil layer is applied with straw with a fineness of 3 to 5 cm, and at the same time, a straw rot accelerator is added, which is conducive to the decomposition of the straw; the 20 to 30 cm soil layer is applied with straw with a fineness of 5 to 8 cm; 30 to 40 cm of the soil layer is applied. Apply straw with a fineness of 8-10 cm. The composting degree of straws applied from top to bottom gradually decreased.

[0062] A slightly salin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com