Laser fixing device and fixing method for c-mount laser welding line

A fixed device, laser technology, applied in the direction of lasers, laser parts, semiconductor lasers, etc., can solve the problems of large deviation of laser welding line position, difficult to guarantee consistency, affecting product quality, etc., to achieve simple structure, convenient and reliable operation. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

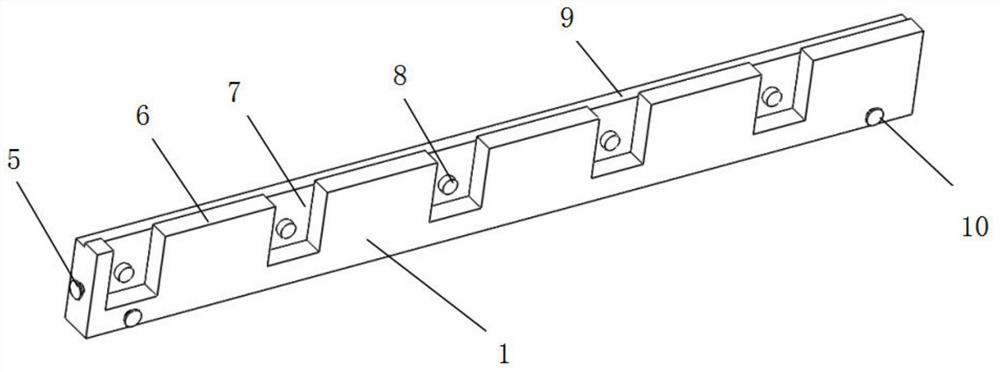

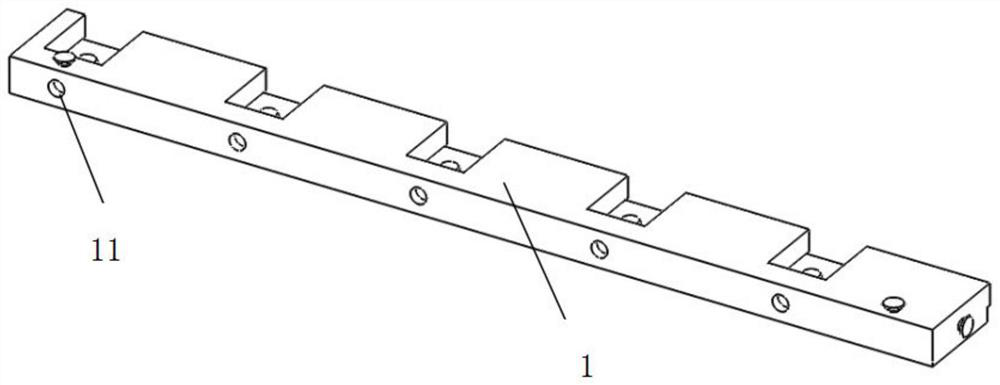

[0042] like Figure 1-Figure 9 As shown, this embodiment provides a laser fixing device for a C-mount laser welding wire, including a fixing bar 1, a pressing sheet 2, and a retaining bar 3; There are fixing pins I5, N evenly arranged retention grooves 7 are arranged in the middle of the fixing bar 1, a fixing column 8 is arranged in the middle of each fixing slot 7, and a platform 6 is arranged on one side of each fixing slot 7, The upper end of the fixing strip 1 is provided with a concave edge 9, the two sides of the front end of the fixing strip 1 are respectively provided with fixing pins II 10, and the lower end of the fixing strip 1 is provided with N evenly arranged circular holes 11; A raised edge 16 is provided, N evenly arranged gaps 13 are arranged in the middle of the pressing sheet 2, and N evenly arranged protrusions 17 are arranged on one side of the gap 13 at the lower end of the pressing sheet 2, and one side of each protrusion 17 is respectively provided wit...

Embodiment 2

[0052] Utilize the method for fixing the C-mount laser with the laser fixing device of the C-mount laser welding wire provided in Example 1, and the specific steps are as follows:

[0053] (1) Take out the laser fixing device, push the side edge 12 of the tablet 2 upwards, move the tablet 2 to the uppermost end of the device, push the bar 3 down, move the bar 3 to the lowermost end of the device, and expose the fixing groove to the greatest extent 7. It is convenient to place the heat sink block 22;

[0054] (2) Clamp the heat sink block 22 of the C-mount laser 18 with tweezers, align the fixing hole 23 of the heat sink block 22 with the fixing post 8 on the fixing bar 1, and place the heat sink block 22 in the fixing slot 7;

[0055] (3) After the heat sink blocks 22 are placed in all the fixing grooves 7, gently push the bar 3 upward to move the bar 3 to the uppermost end, and press the pressing piece 2 downward, and the pressing piece 2 passes through the guide groove I14 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com