Novel replaceable single-layer metal layout structure of TVS

A layout structure and metal technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of occupying a large area and reducing the wiring area of the circuit board, and achieve uniform distribution of current, good quality and performance, and reduced The effect of possible errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

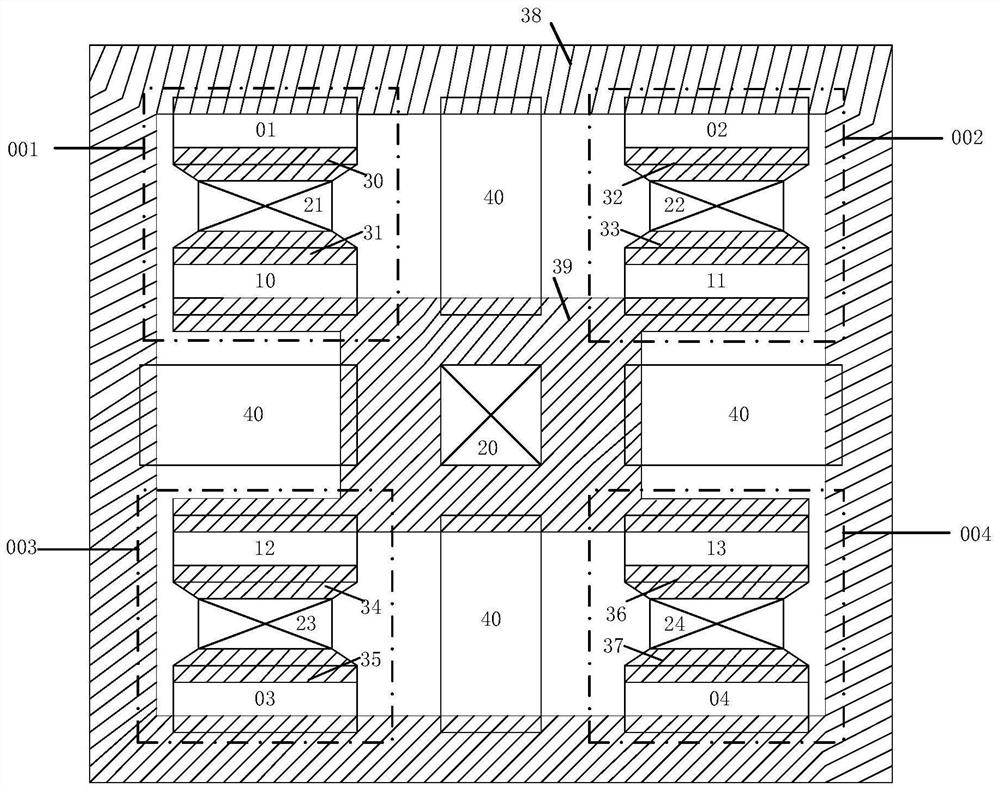

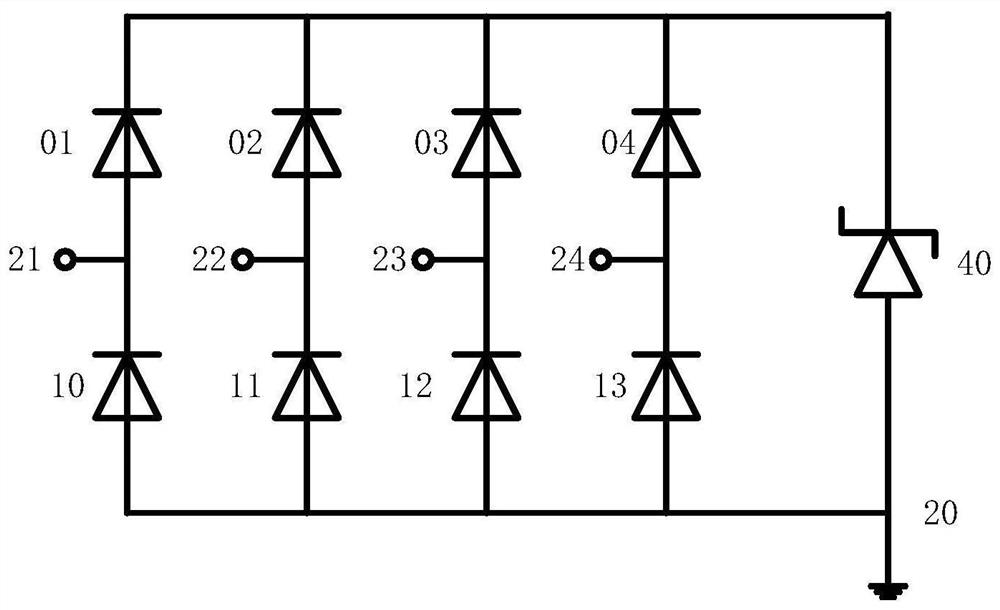

[0024] like figure 1 As shown, this embodiment provides a novel alternative TVS single-layer metal layout structure, including: a first diode 01, a second diode 02, a third diode 03, and a fourth diode 04 , the fifth diode 10, the sixth diode 11, the seventh diode 12, the eighth diode 13, the zener tube 40; the first electrode pad 20, the second electrode pad 21, the third Electrode pad 22, fourth electrode pad 23, fifth electrode pad 24; first metal 30, second metal 31, third metal 32, fourth metal 33, fifth metal 34, sixth metal 35, The seventh metal 36, the eighth metal 37, the ninth metal 38, and the tenth metal 39;

[0025] Among them, the first diode 01, the fifth diode 10, the second electrode pad 21, the first metal 30 and the second metal 31 form the first diode region 001, and the first diode region 001 is located in the layout The upper left corner of the structure; wherein the second electrode pad 21 is connected to the p-region of the first diode 01 through the ...

Embodiment 2

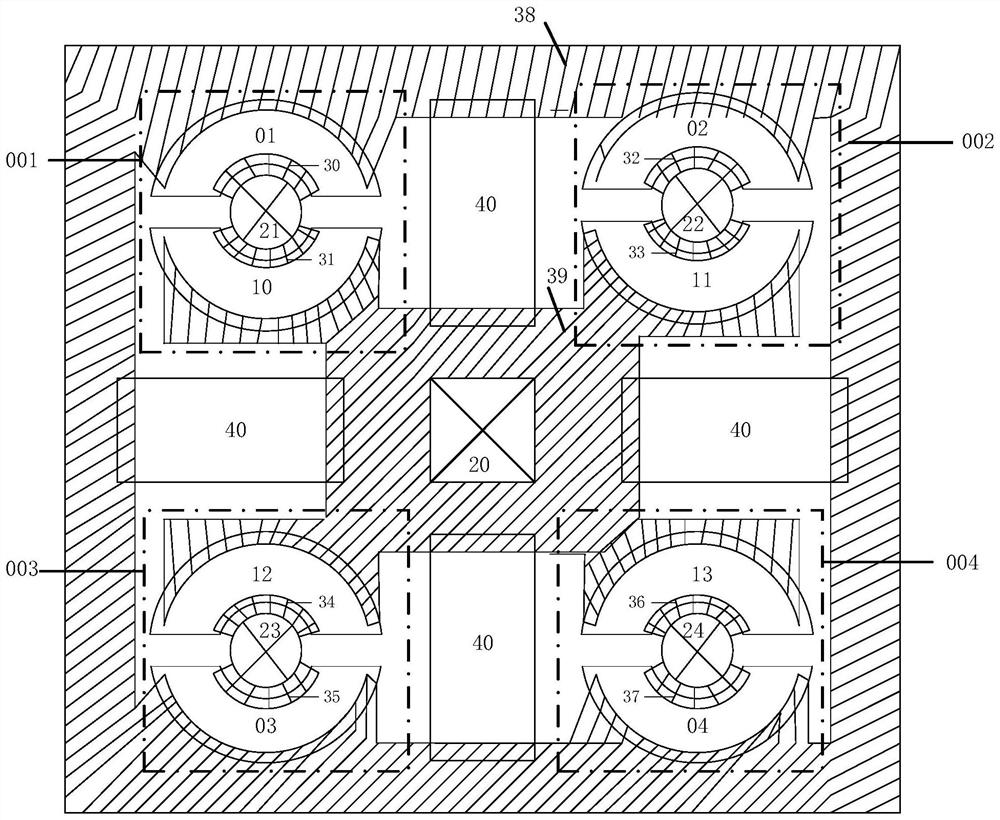

[0032] like image 3 As shown, the difference between this embodiment and Embodiment 1 is: the first diode 01, the second diode 02, the third diode 03, the fourth diode 04, the fifth diode 10, the first diode The six diodes 11, the seventh diode 12, and the eighth diode 13 are circular, and the second electrode pad 21, the third electrode pad 22, the fourth electrode pad 23, and the fifth electrode pad 24 is round.

Embodiment 3

[0034] The difference between this embodiment and Embodiment 1 is that the Zener transistor 40 is a thyristor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com