High-voltage composite umbilical cable and manufacturing process thereof

A production process and umbilical cable technology, applied in the direction of cable/conductor manufacturing, insulating cables, conductor/cable insulation, etc., can solve the problems of complex umbilical cable manufacturing process, increased equipment costs, offshore construction costs, and affecting production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

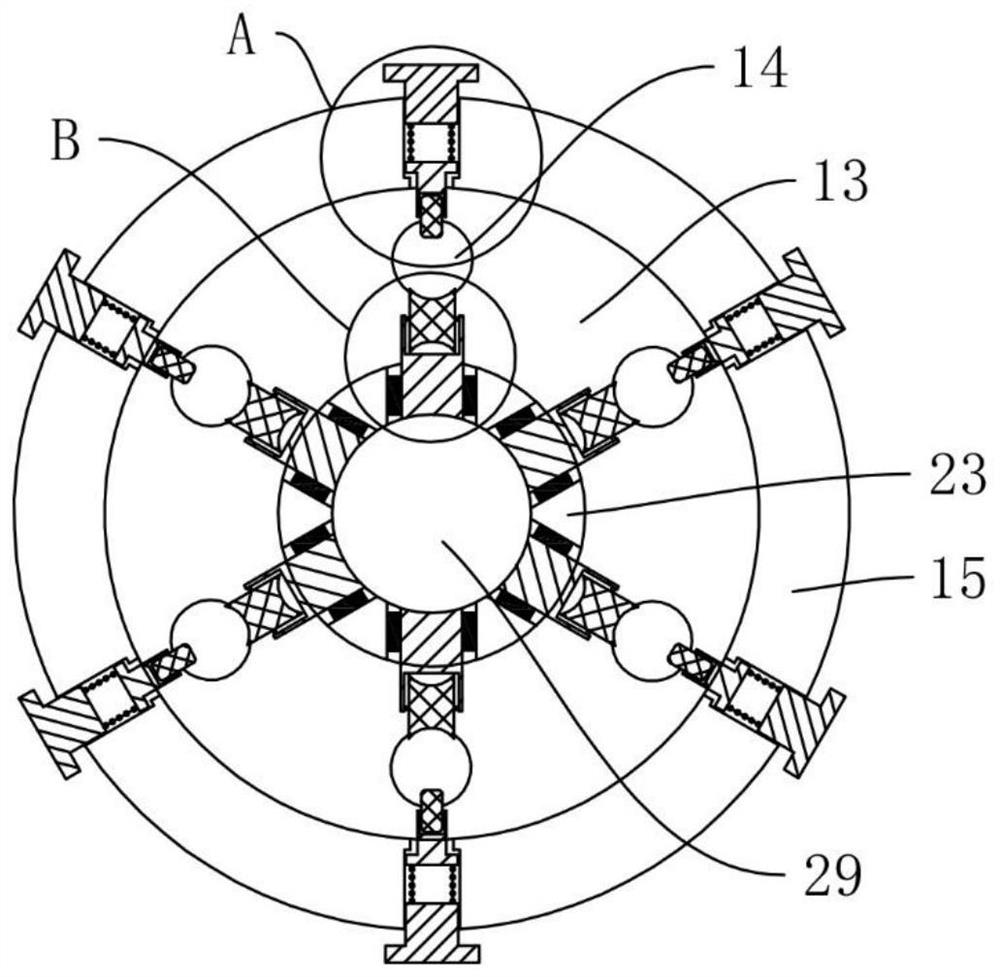

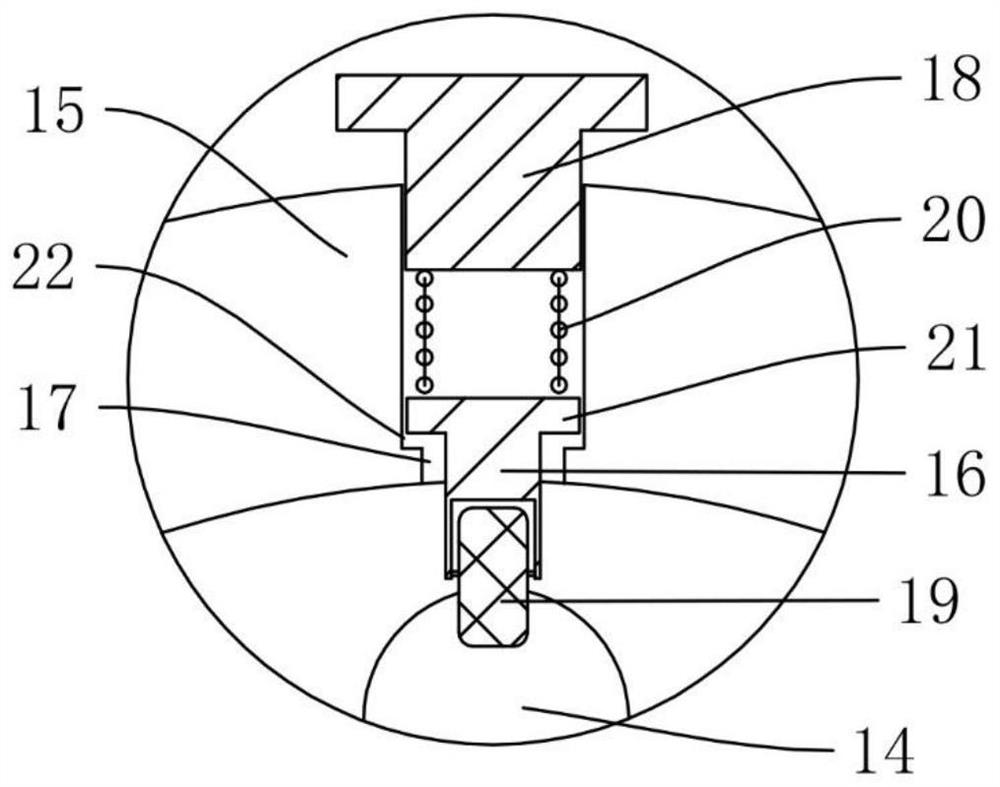

[0035] The present invention is further explained in conjunction with the accompanying drawings.

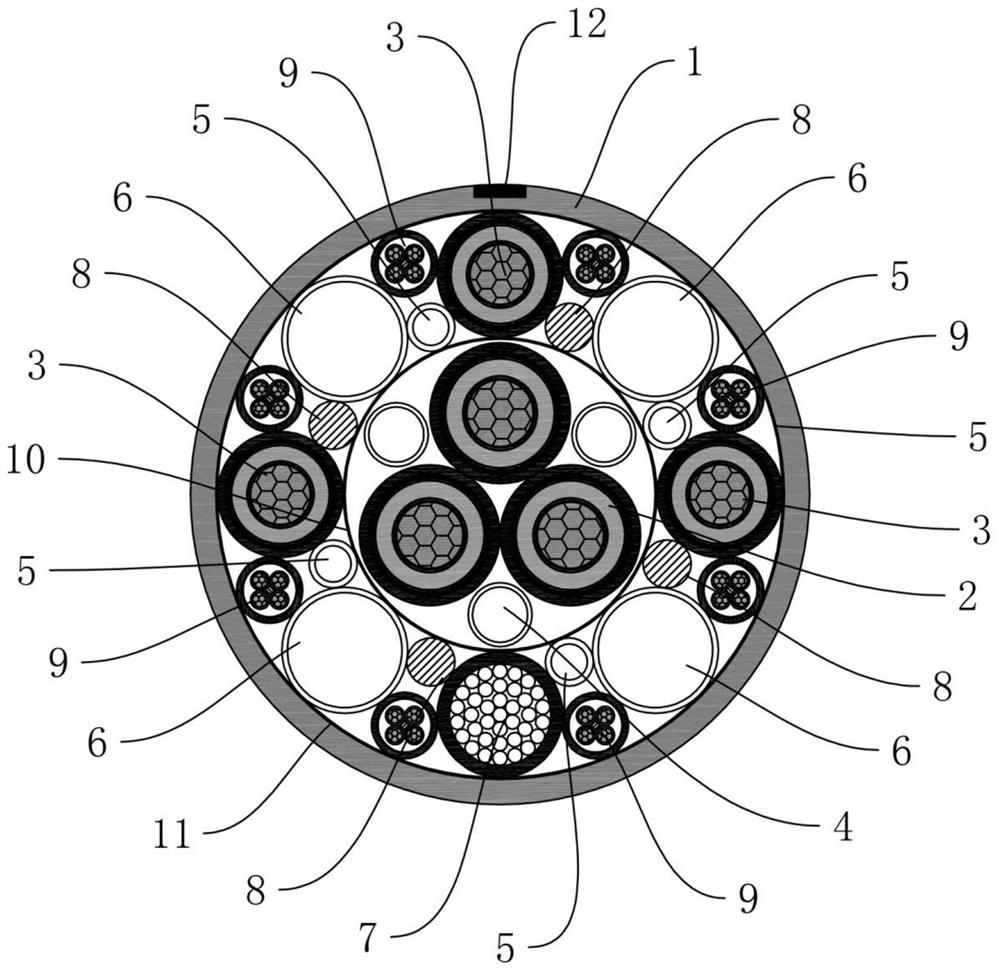

[0036] see figure 1 A high-voltage composite umbilical cable shown includes an inner layer functional unit group, an outer layer functional unit group disposed on the outer periphery of the inner layer functional unit group, and an outer sheath 1 covering the outer layer functional unit group.

[0037]The inner layer functional unit group includes three inner layer medium voltage cable units 2, three inner layer filled steel pipe units 4, the outer layer functional unit group includes four outer layer steel pipe units 6, one steel strand unit 7, three outer layer Medium-voltage cable unit 3, eight low-voltage cable units 9, four filling bodies 8, and four outer-layer filled steel pipe units 5.

[0038] The three inner-layer medium-voltage cable units 2 are arranged at the center and distributed in an equilateral triangle. The inner-layer filled steel pipe unit 4 is arranged betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com