Working condition steady state detection method and process optimization method

A detection method and steady-state technology, applied in the fields of digital data information retrieval, special data processing applications, instruments, etc., can solve the problems of difficult to determine the window, difficult to control and adjust, complex algorithm, etc., to improve reliability and have universality. Sex, the effect of simple test methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

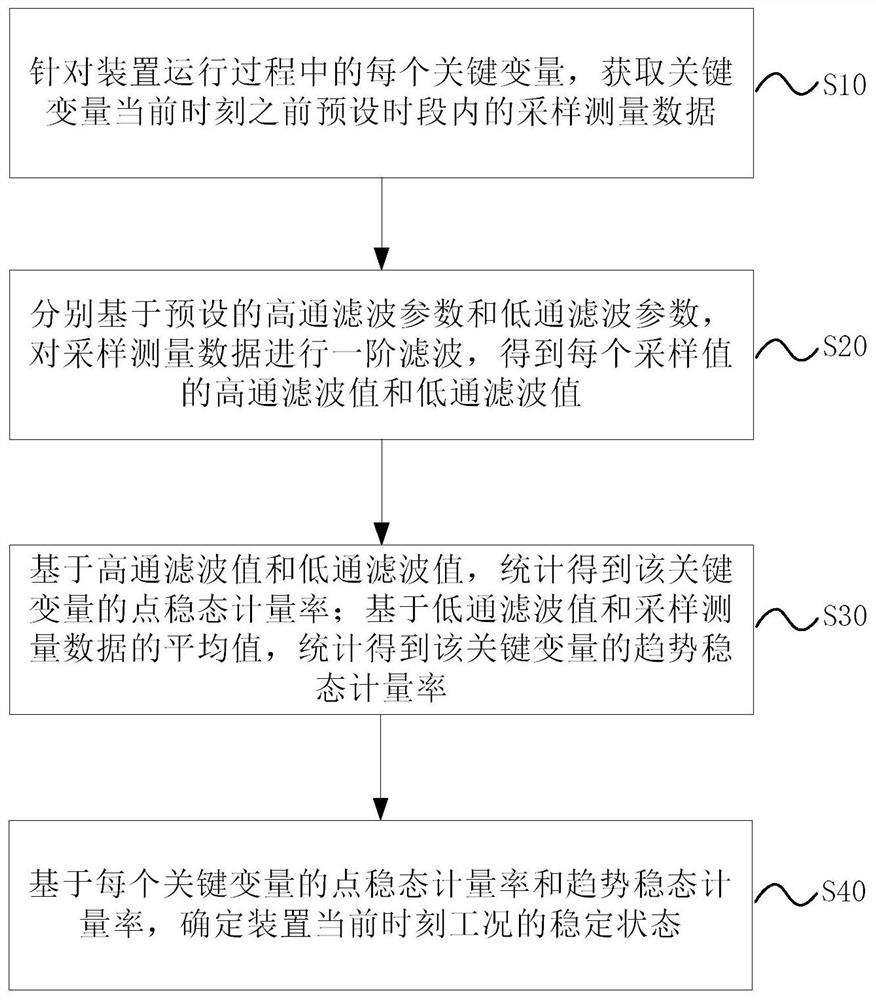

[0063] figure 1 It is a schematic flow chart of the working condition steady-state detection method in an embodiment of the present application, such as figure 1 As shown, the method includes:

[0064] S10. For each key variable in the operation process of the device, obtain the sampling measurement data of the key variable within a preset period of time before the current moment;

[0065] S20. Perform first-order filtering on the sampled measurement data based on preset high-pass filter parameters and low-pass filter parameters, respectively, to obtain a high-pass filter value and a low-pass filter value for each sampled value;

[0066] S30. Based on the high-pass filter value and the low-pass filter value, statistically obtain the ratio of the sampled value whose filter absolute difference satisfies the preset point steady-state interval in the sampled measurement data, and use it as the point steady-state metering rate of the key variable;

[0067] Based on the low-pass ...

Embodiment 2

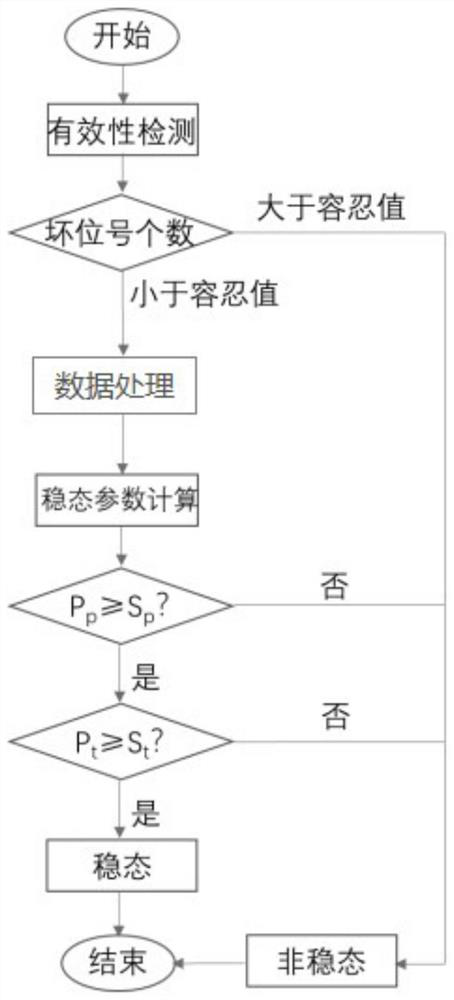

[0103] figure 2 It is a schematic flow chart of the working condition steady-state detection method in another embodiment of the present application, combined below figure 2 Each step in this embodiment is described in detail.

[0104] It should be noted that the tag number is the abstraction of data points in the industrial site. The real-time data of the industrial site is usually collected from the equipment or the control system in real time, and the time-based sequential data is based on the tag number. Typical tag data includes Value, timestamp and status code three fields. In this embodiment, for each key variable in the operation process of the device, the acquired sampling measurement data is bit number data, and the acquisition method is obtained by subscribing from the real-time database by the client.

[0105] S1. Perform a validity check on the acquired tag data.

[0106] Possible failures due to instrumentation, communication, etc. during the production and ...

Embodiment 3

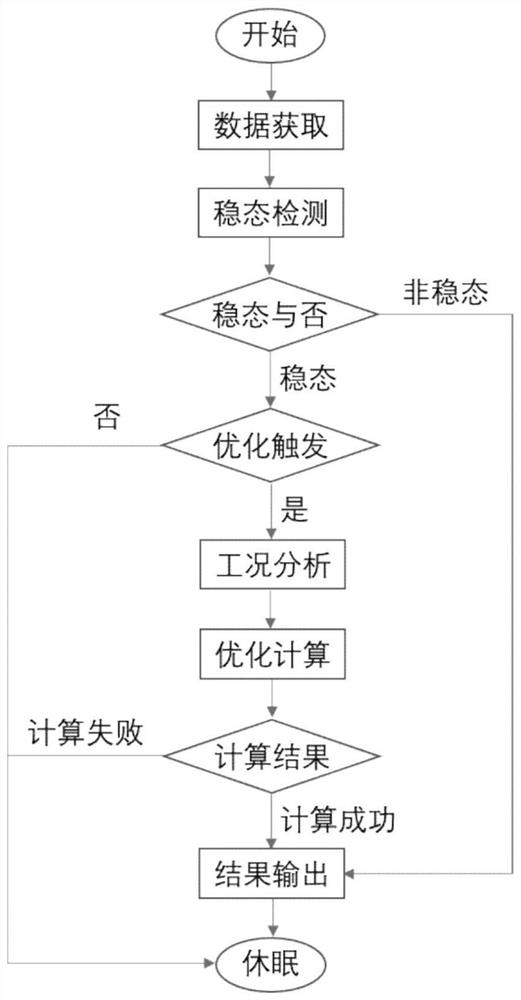

[0149] In a second aspect, the present application provides a method for process optimization based on a DCS system, the method comprising:

[0150] S100. Aiming at the target device, the process optimization system extracts the tag data of all key variables through a sliding time window to obtain window data;

[0151] S200. The process optimization system performs steady-state detection on the window data by the method described in any one of the above-mentioned first aspects, obtains the detection result under the current working condition of the target device, and sends the detection result to the DCS system, so that in the DCS system on display;

[0152] S300, the DCS system regulates the target device based on the operating instructions issued by the operator according to the detection results;

[0153] S400, execute steps S100-S300 in a loop until the target device is in a stable state under the current working condition;

[0154] S500. When the preset optimization con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com