Pressure pipeline ultrasonic detection device and detection method thereof

A technology for pressure pipelines and detection devices, which can be applied to measurement devices, use sonic/ultrasonic/infrasonic waves to analyze solids, and use sonic/ultrasonic/infrasonic waves for material analysis, etc. Reduce the possibility of roller jamming and improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following is attached Figure 1-4 The application is described in further detail.

[0041] The embodiment of the present application discloses an ultrasonic detection device for a pressure pipeline.

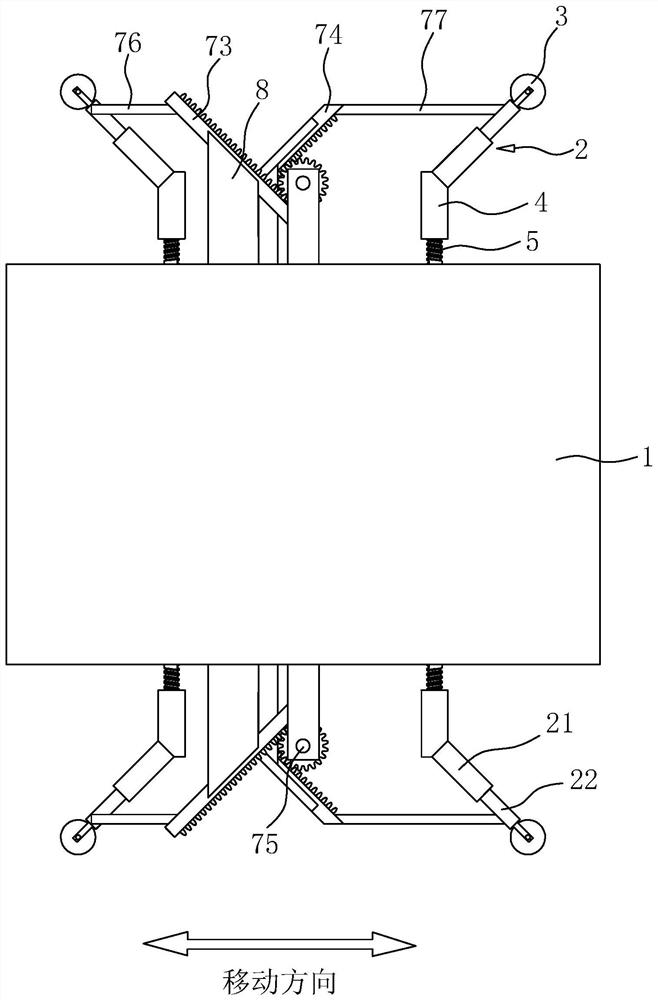

[0042] refer to figure 1 , The pressure pipeline ultrasonic detection device includes an instrument device 1, and the instrument device 1 is used for detecting defects of the pipeline. Move the instrument device 1 in the pipeline along the axial direction of the pipeline, figure 1 The moving direction shown in is the moving direction of the instrument device 1 , and the instrument device 1 uses ultrasonic waves to detect the pipeline during the moving process.

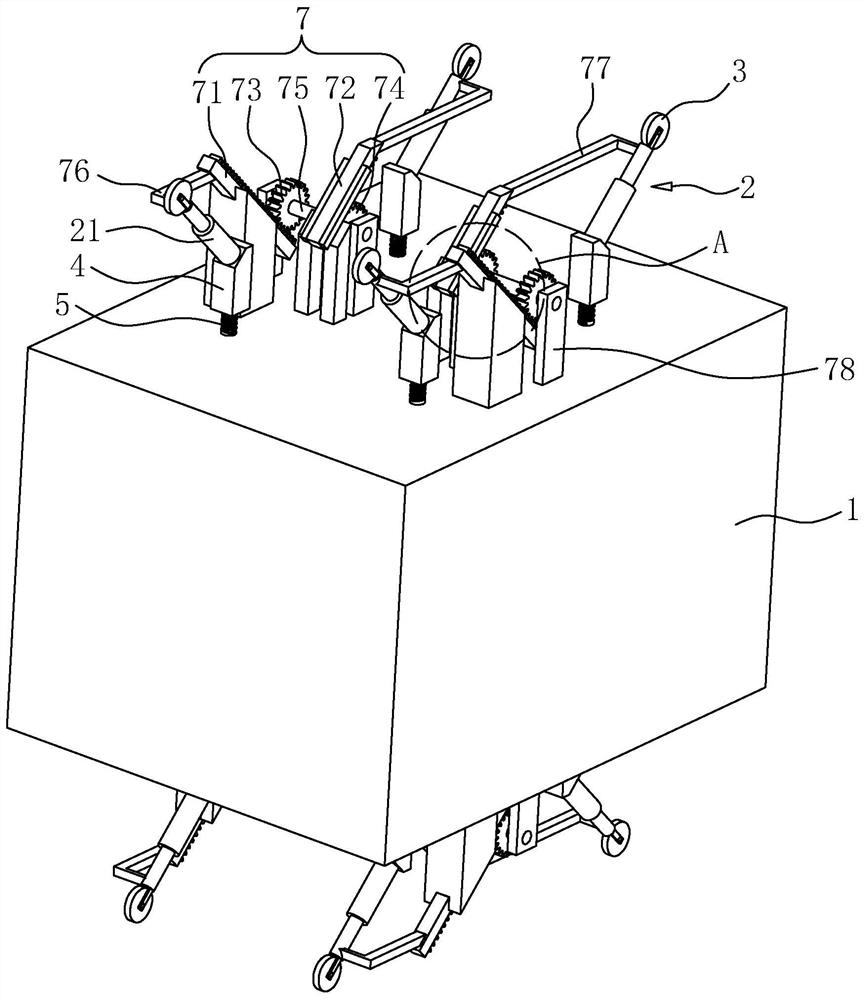

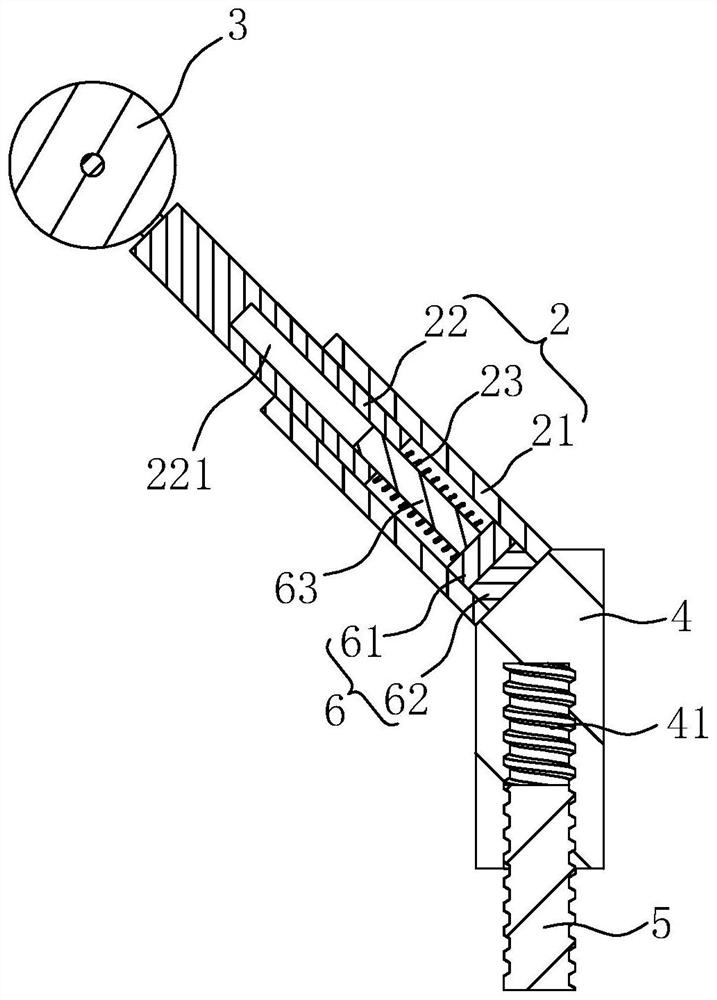

[0043] refer to figure 2 , the instrument device 1 is connected with a supporting mechanism, and the supporting mechanism includes several telescopic assemblies 2 , and the supporting mechanism includes four telescopic assemblies 2 in this embodiment. Four telescopic assemblies 2 are distributed around th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com