Wearable bra for measuring thermal resistance of bra

A wearable and bra technology, applied in the field of bras, can solve the problems of inability to characterize the performance of fabrics, the inability of thermal mannequins to accurately measure heat, and the inability to measure heat more accurately, so as to achieve the effect of convenient movement and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

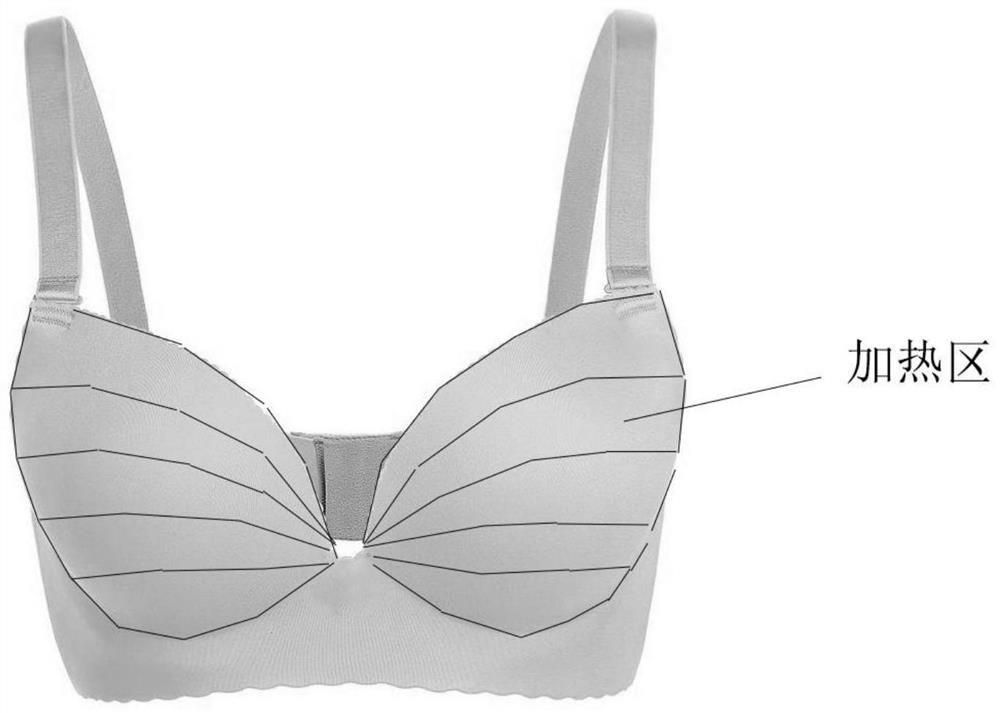

[0033] A wearable bra for measuring the thermal resistance of the bra, comprising the following steps:

[0034] Wear the wearable electric heating bra on the mannequin, and then put on the bra to be tested. The heating part of the wearable electric heating bra can be adjusted according to the style of the bra, so that the heat passing through the bra can be accurately measured , and then calculate the thermal insulation index of the bra product, such as: Cro value;

[0035] The formula for calculating the Cro value is:

[0036]

[0037] In the formula:

[0038] R cl is the thermal resistance of the bra, clo;

[0039] A s is the area of the heated area covered by the bra to be tested, m 2 ;

[0040] t s is the area-weighted average temperature of the heated area covered by the bra to be tested, °C;

[0041] t a is ambient temperature, °C;

[0042] h d is the dry heat input power of the area covered by the bra to be tested, W;

[0043] R a is the thermal resist...

Embodiment 2

[0046] Wear the wearable electric heating bra on the mannequin, and then put on the bra to be tested. The heating part of the wearable electric heating bra can be adjusted according to the style of the bra, so that the heat passing through the bra can be accurately measured , and then calculate the thermal insulation index of the bra product, such as: thermal resistance, Cro value;

[0047]

[0048] In the formula:

[0049] R cl is the thermal resistance of the bra, clo;

[0050] A si is the area of the i-th heating area covered by the bra to be tested, m 2 ;

[0051] t si is the average temperature of the i-th heating area covered by the bra to be tested, °C;

[0052] t a is ambient temperature, °C;

[0053] h di is the dry heat input power of the i-th section heating area covered by the bra to be tested, W;

[0054] R a is the thermal resistance clo of the boundary layer air.

[0055]The more partitions, the more types of bras are suitable for measurement, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com