Dry deslagging air leakage control device for power station boiler

A technology for control devices and power plant boilers, applied in the field of dry slag discharge and air leakage control devices for power plant boilers, which can solve the problems of fast hot air discharge and affecting boiler operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

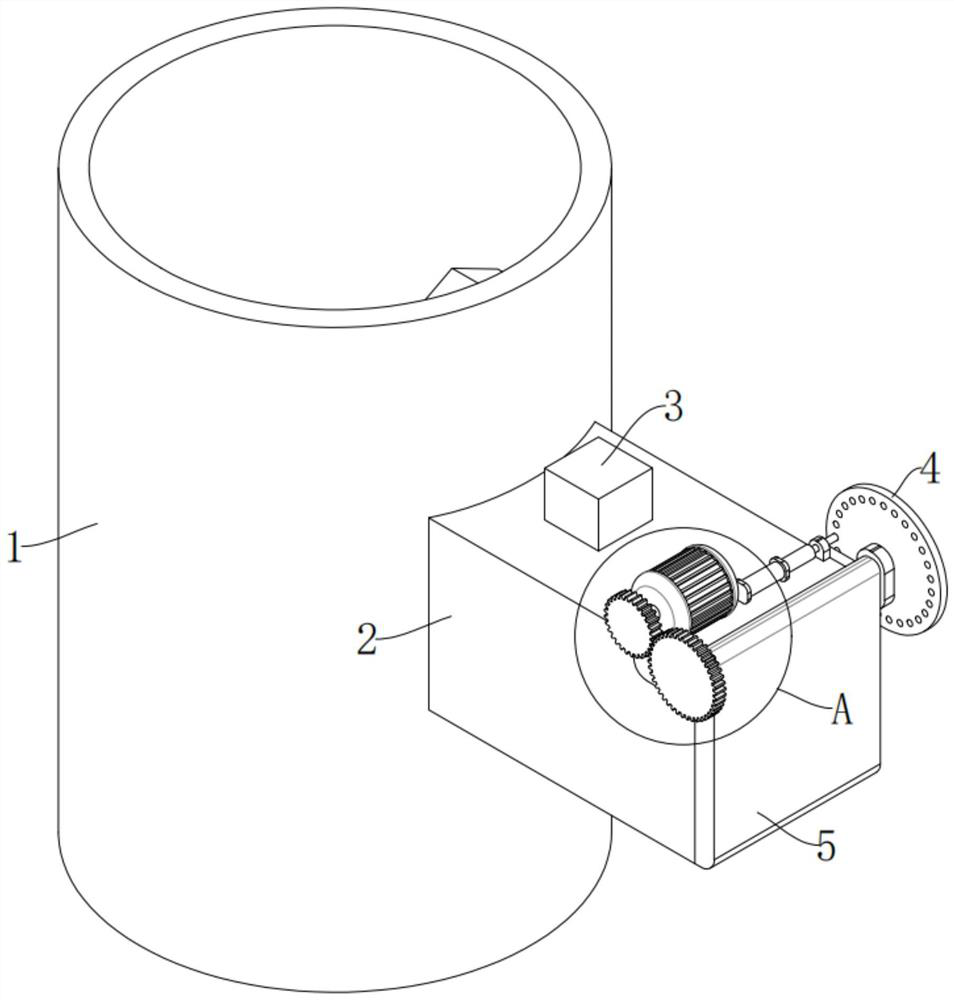

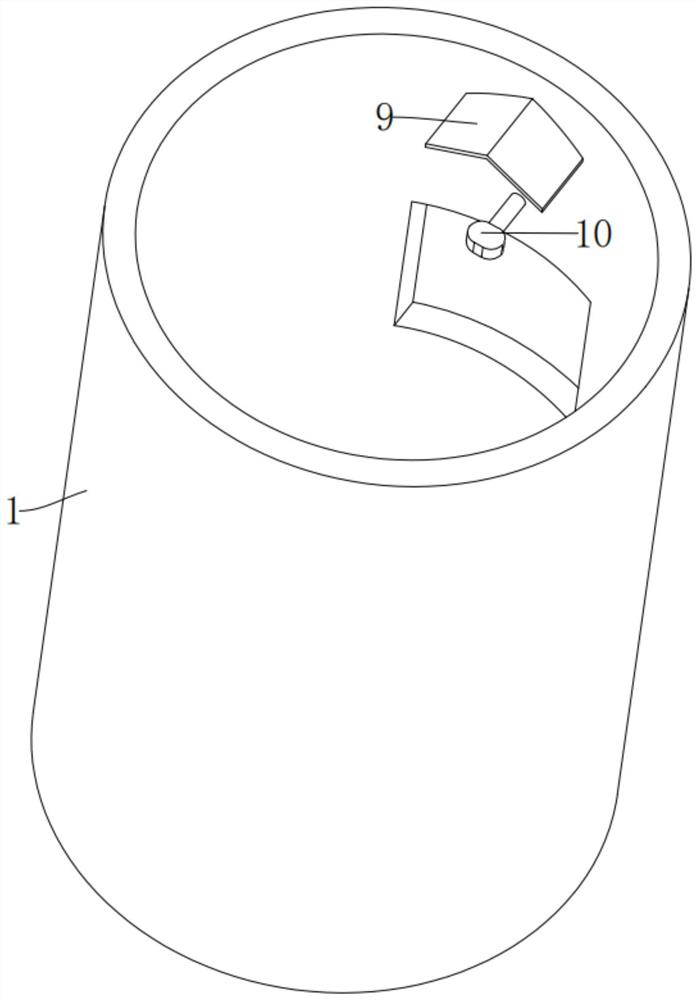

[0034] see Figure 1-5 , the technical solution provided by this embodiment is as follows:

[0035] A power plant boiler dry slag discharge air leakage control device, comprising:

[0036] Slag discharge pipe 1;

[0037] Exhaust pipe 2, the exhaust pipe 2 is fixedly connected to the circumferential surface of the slag discharge pipe 1, and the exhaust pipe 2 communicates with the slag discharge pipe 1;

[0038] The installation mechanism is arranged on the exhaust pipe 2;

[0039] The baffle 5, the baffle 5 is installed on the installation mechanism through the rotation of the rotating shaft 15;

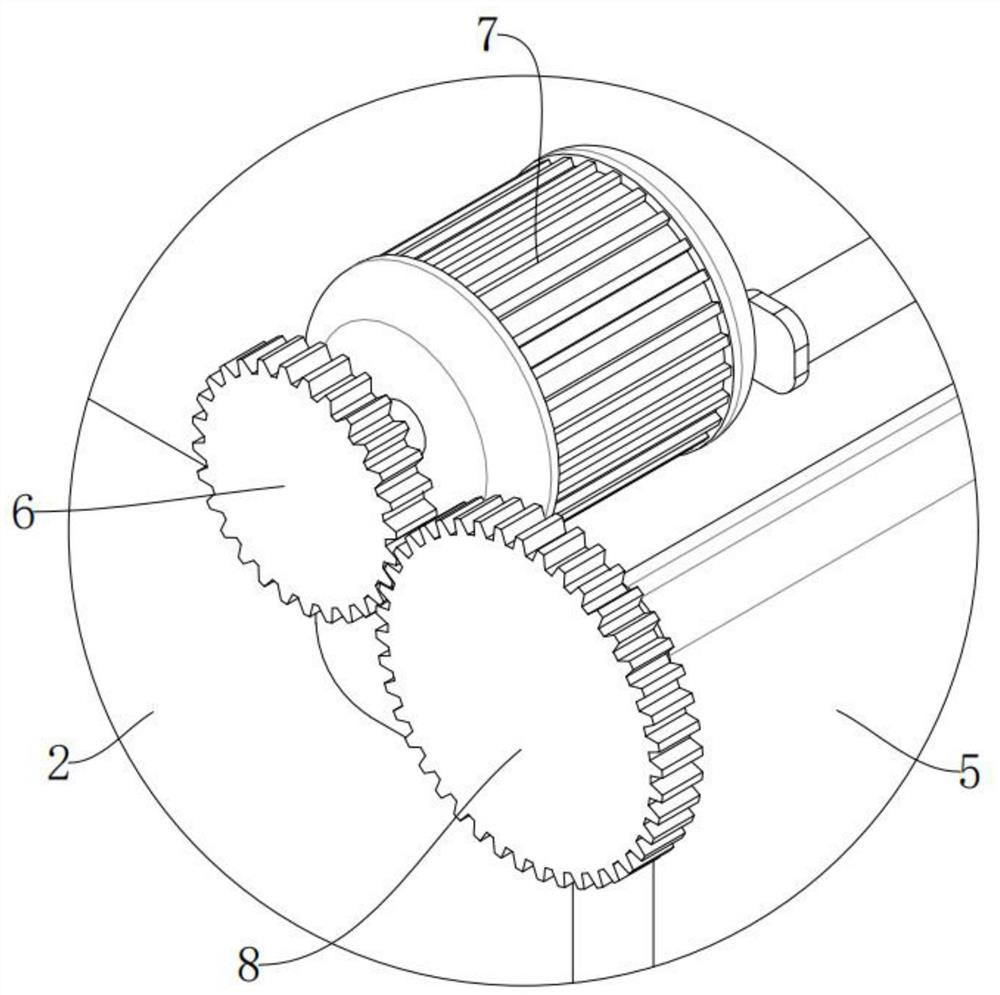

[0040] The servo motor 7 is fixedly connected to the upper end of the exhaust pipe 2;

[0041] Transmission mechanism, the transmission mechanism is arranged on the output end of the servo motor 7, and the transmission mechanism is also connected with the rotating shaft 15 to realize the rotation of the rotating shaft 15;

[0042] A limit mechanism, the limit mechanism is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com