Prefabricated assembly type ancient building reinforcing and mounting structure

A technology for prefabricated assembly and installation of structures, which is applied in the direction of building components, building reinforcements, building structures, etc., and can solve problems such as inclination offset, affecting the stability of connections, and blocking connecting steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

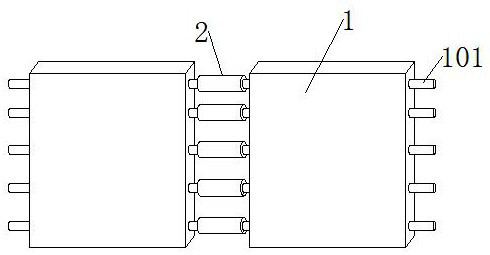

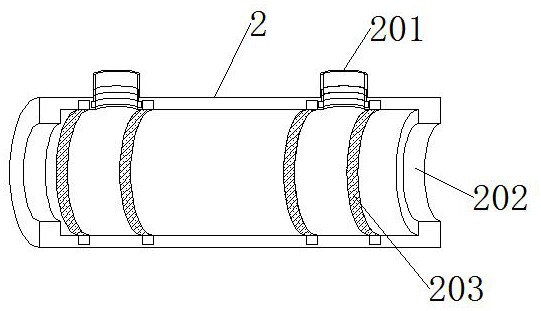

[0023] Please refer to Figure 1 to Figure 6

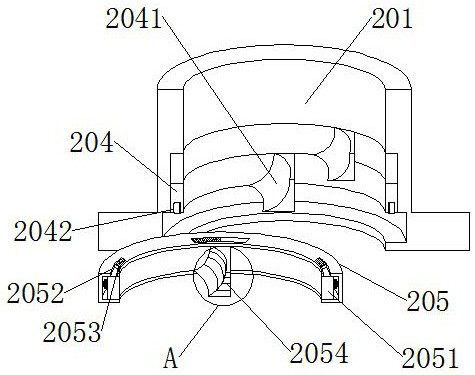

[0024] A prefabricated ancient building reinforcement installation structure, comprising: a main body 1, the main body 1 is connected together by connecting steel bars 101 protruding from the surroundings, and the connecting steel bars 101 face toward each other and one end of which is in contact with each other and the penetration part is carried out in the grouting sleeve 2 connection, the top of the grouting sleeve 2 is provided with a grouting port 201 on the top opening, and the two ends of the grouting sleeve 2 are fixedly connected with a sealing ring 202, and the agitation ring 204 and the transmission ring 205 are overlapped and arranged in the groove on the inner wall of the grouting port 201. The limiting ring 203 is a circular ring with one side threaded to fit the transmission ring 205;

[0025] Wherein, the grouting sleeve 2 includes a grouting port 201, a sealing ring 202, a limit ring 203, an agitation ring 204 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com