Combined pneumatic precast concrete pavement paving method

A prefabricated concrete and pavement laying technology, applied to pavements, roads, roads and other directions paved with prefabricated blocks, can solve the problems of broken bricks, poor integrity, road erosion, etc., to reduce the possibility of water seepage and improve the use of Longevity, the effect of improving the flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

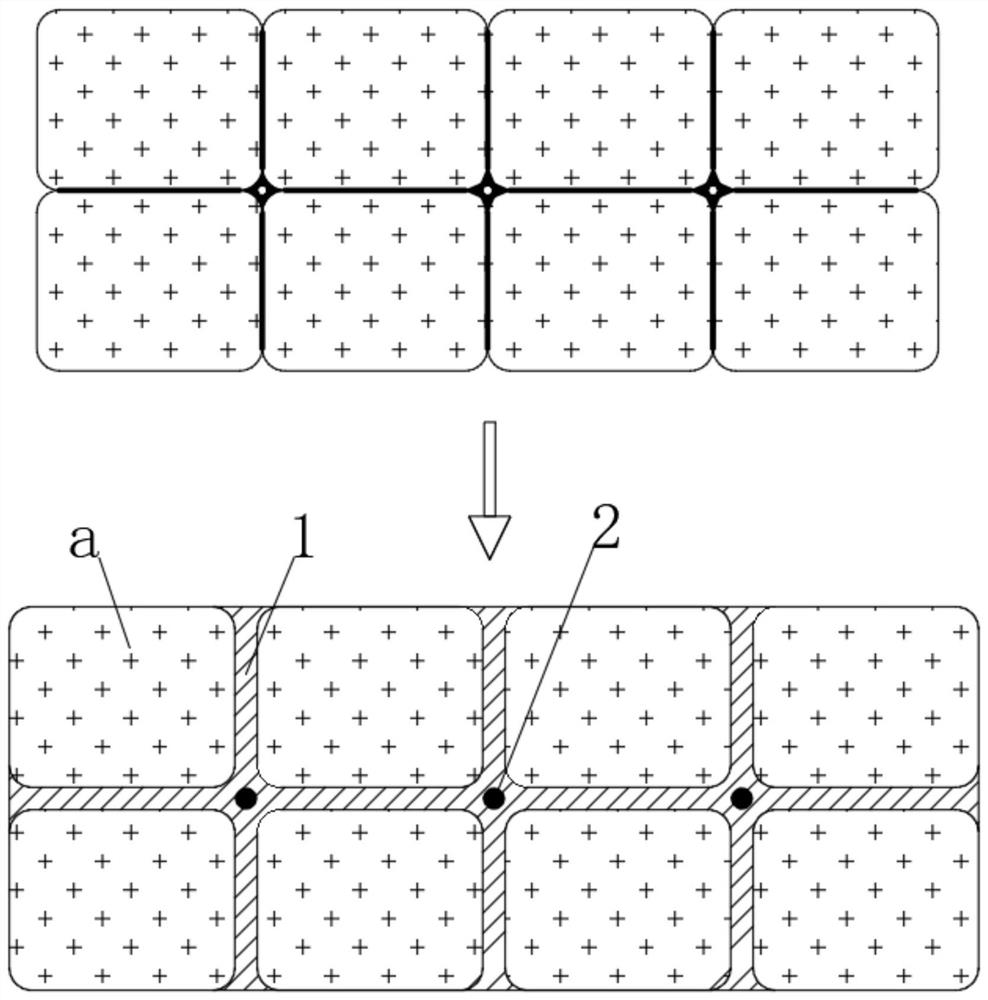

[0042] see figure 1 , a combined pneumatic type precast concrete pavement laying method, comprising the following steps:

[0043] S1. First, clean the road surface to be constructed, excavate trenches, lay the roadbed, and level the roadbed after laying;

[0044] S2. Lay the pneumatic soft trough frame on the roadbed, and set the limit plate at the edge of the pneumatic soft trough frame, and the limit plate is fixed and buried on the roadbed;

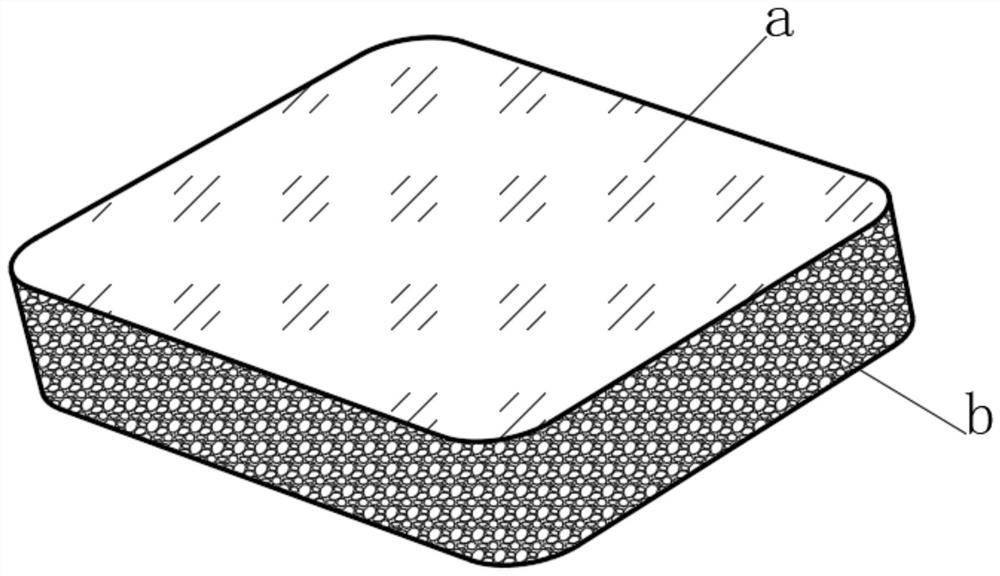

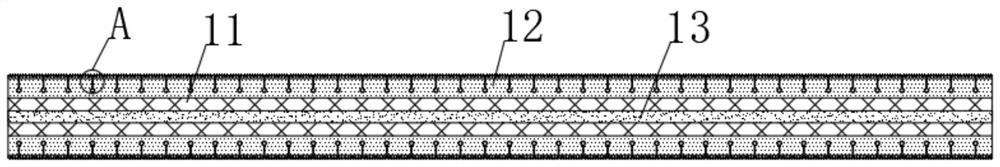

[0045] S3, coating the concrete layer on the bottom of the pneumatic soft trough frame, and then laying the prefabricated concrete bricks on the pneumatic soft trough frame one by one;

[0046] S4. Inflate the pneumatic soft groove frame, adjust the position of two adjacent concrete bricks and the flatness of the upper surface;

[0047] S5. After the adjustment, fill the inside of the pneumatic soft trough with fine stone concrete again until the pneumatic soft trough is fully stretched, and multiple concrete bricks are closely conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com