Preparation method of single-cell microgel

A microgel, single-cell technology, applied in the direction of immobilization on/in an organic carrier, can solve the problems of high manufacturing cost and use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

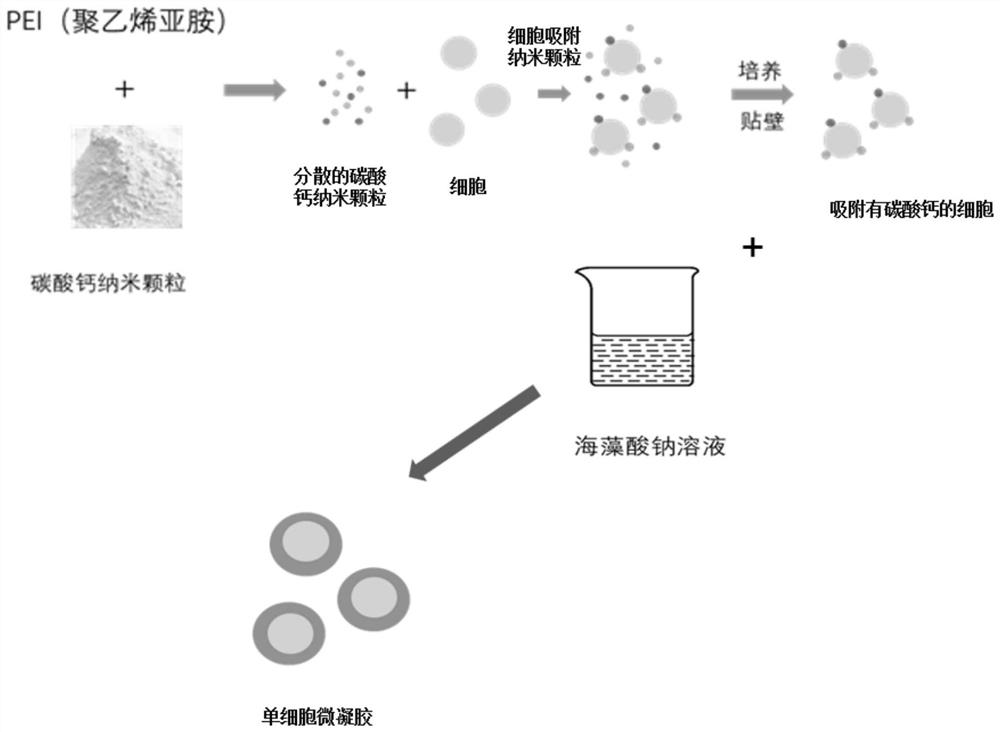

Method used

Image

Examples

preparation example Construction

[0062] The preparation method of the above-mentioned single-cell microgel has at least the following advantages:

[0063] (1) Low cost: the raw materials are at least one of calcium carbonate nanoparticles and barium carbonate nanoparticles, alginate and polycation compounds, the raw materials are easy to obtain and cheap, and the preparation method of the above-mentioned single-cell microgel Do not rely on expensive microfluidic chips, low cost.

[0064] (2) Easy to operate: The above-mentioned single-cell microgel preparation method can realize the preparation of single-cell microgel by solid-liquid mixing and solid-liquid separation, and the operation is simple; and, the traditional single-cell microgel prepared by microfluidic chip Microgels are not easy to collect, separate and process. However, when the single-cell microgels are prepared by the above-mentioned single-cell microgel preparation method, they can be collected, separated and processed by centrifugation. In a...

Embodiment 1

[0071] (1) Sample and reagent preparation:

[0072] Sodium alginate solution: Mix sodium alginate, sodium alginate marked with FITC (FITC sodium alginate) and water evenly to prepare a sodium alginate solution. In the sodium alginate solution, the mass percentage of sodium alginate is 1% sodium alginate, the mass percentage of FITC-sodium alginate is 0.05%, and the cells are Hela cells;

[0073] Polyethyleneimine dispersion: 0.0008g polyethyleneimine (Aladdin E107079, weight average molecular weight 10000) and 1mL deionized water were dispersed under 80kHz ultrasonic for 3 minutes to prepare polyethyleneimine dispersion; In the solution, the concentration of polyethyleneimine is 0.8mg / mL;

[0074] It is standby to take by weighing 0.0099g median particle diameter to be the calcium carbonate nanoparticle of 20nm;

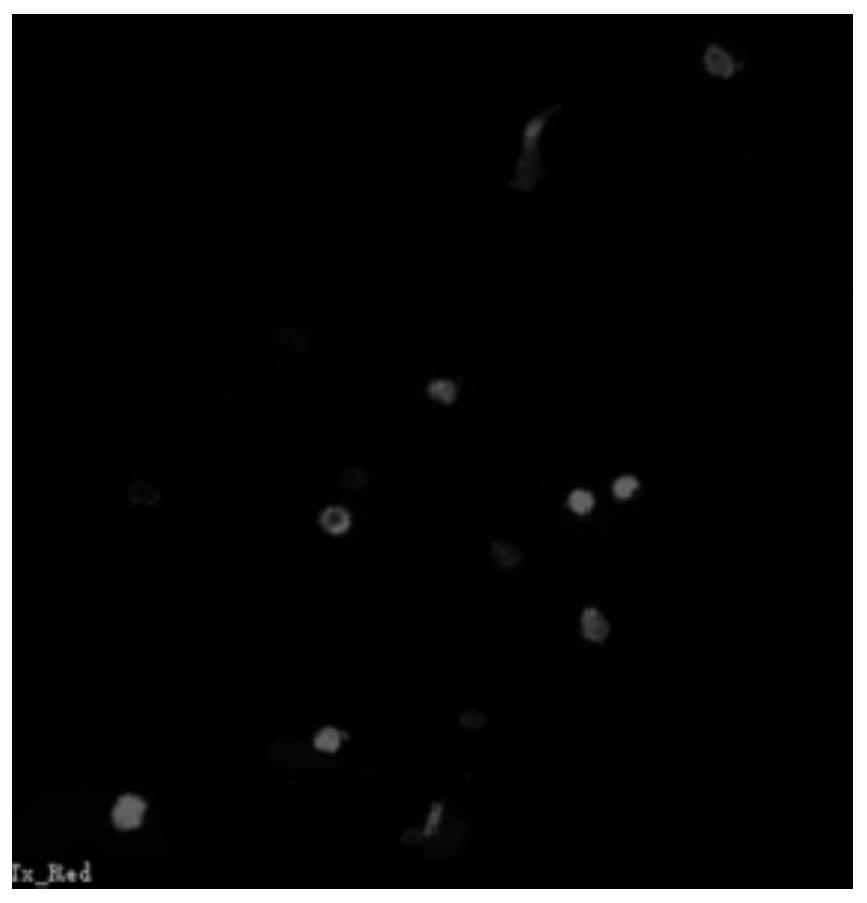

[0075] Cell suspension: 1mL cell suspension whose cell membrane is labeled with red probe (DID), the cell density is 1×10 6 cells / mL; Electron micrographs of cell...

Embodiment 2

[0085] The preparation method of the single-cell gel in this example is roughly the same as the preparation method of the single-cell gel in Example 1, the difference is that in this example, the concentration of polyethyleneimine in the polyethyleneimine dispersion is 0.6 mg / mL, the potential of positively charged calcium carbonate nanoparticles in water is 14.1mV.

[0086] The single-cell gel prepared according to the preparation method of this example is as follows: Figure 9 to Figure 11 shown. Figure 9 is the image under the red channel; Figure 10 is the image under the green channel; Figure 11 is the image under the merged channel.

[0087] Depend on Figure 9 to Figure 11 It can be seen that the single-cell microgel of this example was successfully prepared, there was gel on the cell surface, and there was fluorescence under the red and green channels. Through the fluorescence of the combined channel, it was found that the encapsulation rate of the single-cell m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com