A metal door and window lock hole grinding device

A technology for metal doors, windows and keyholes, applied in metal processing equipment, grinding machines, grinding machine parts, etc., can solve the problems of inconvenience and poor adaptability, and achieve the effect of convenient use, small size, and avoiding excessive grinding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

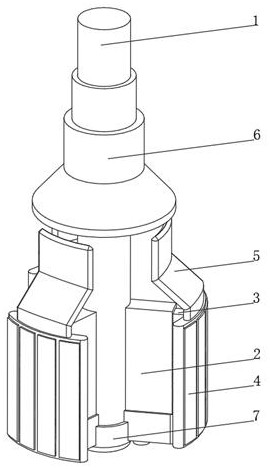

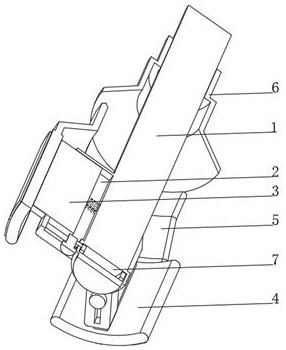

[0034] see Figure 1-4 , the present invention provides a technical solution: a metal door and window lock hole grinding device, specifically comprising:

[0035] A fixed column 1, one side of the fixed column 1 is fixedly connected with a fixed frame 2, the inner wall of the fixed frame 2 is slidably connected with a telescopic plate 3, and one side of the telescopic plate 3 extends to the outside of the fixed frame 2 and is fixedly connected with an arc-shaped grinding device 4;

[0036] Extrusion plate 5, this extrusion plate 5 is arranged on the top of arc grinding device 4, and extrusion plate 5 is provided with vertical and inclined two sections;

[0037] Squeeze the shrink tube 6, the squeeze shrink tube 6 is sleeved on the fixed column 1 and screwed with the fixed column 1, the shape of the squeezed shrink tube 6 matches the shape of the squeeze plate 5;

[0038] A control device 7, the control device 7 is arranged at the bottom of the fixed column 1 and fixedly conne...

Embodiment 2

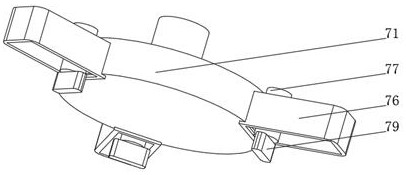

[0044] see Figure 1-5 On the basis of Embodiment 1, the present invention provides a technical solution: the arc-shaped grinding device 4 includes an arc-shaped mounting plate 41, and both ends of the arc-shaped mounting plate 41 are fixedly connected with an arc-shaped hinge plate 42, and the arc-shaped hinge plate 42 There are multiple groups and damping pads are provided at the joints between the two. The outer side of the arc-shaped installation plate 41 is provided with an installation groove 43. The inner wall of the installation groove 43 is provided with an arc-shaped grinding plate 44. One side of the arc-shaped installation plate 41 is connected to the telescopic The plate 3 is fixedly connected, and the inner wall of the installation groove 43 is connected with the side of the arc-shaped grinding plate 44 through the groove block.

[0045] An arc-shaped grinding device 4 is provided, and the inside of the arc-shaped grinding device 4 is provided with an arc-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com