Screening and crushing all-in-one machine for coal mining

An all-in-one machine and screening technology, which is applied in the direction of solid separation, magnetic separation, chemical instruments and methods, etc., can solve the problems of coal block retention and low iron removal efficiency, and achieve the goal of increasing the iron removal area and improving iron removal efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

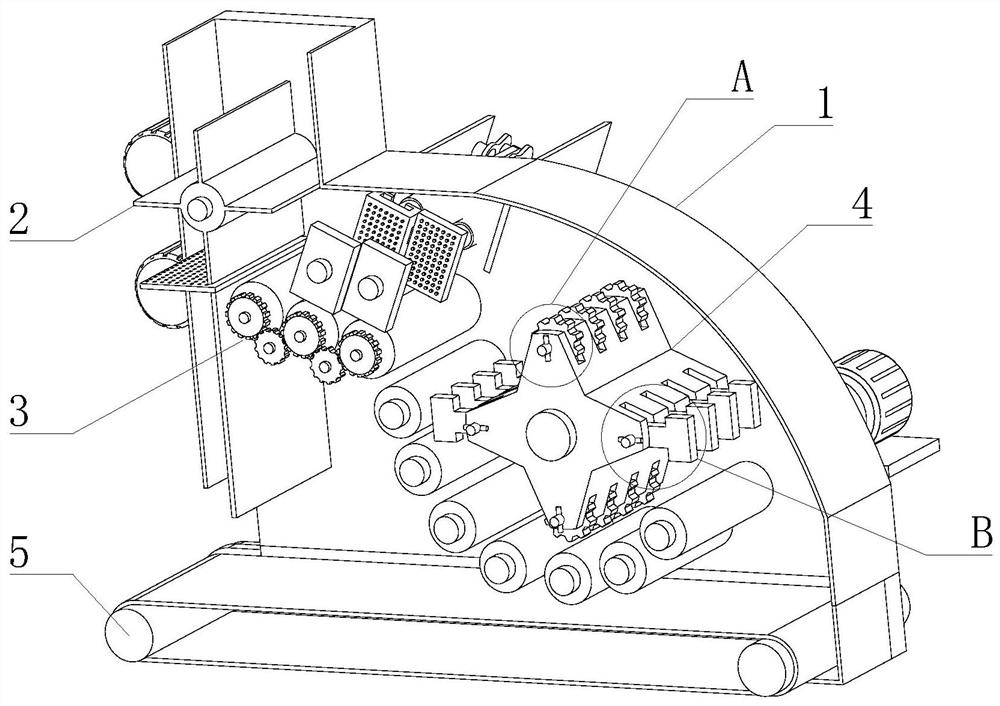

[0053] like Figure 1-16 As shown, the present invention provides a screening and crushing integrated machine for coal mine development, which includes a cabinet 1, an iron removal device 2 is fixedly installed at the left end of the cabinet 1, and a primary screen is fixedly installed inside the cabinet 1 and on the right side of the iron removal device 2 In the sub-crushing device 3, a secondary screening and crushing device 4 is fixedly installed inside the cabinet 1 and on the right side of the primary screening and crushing device 3, and a transport device 5 is fixedly installed at the lower end of the cabinet 1.

[0054] In this embodiment, the iron removal device 2 can remove the iron lumps mixed in the coal lumps to prevent the iron lumps from causing damage to the internal equipment, and the primary screening and crushing device 3 is responsible for transporting the coal lumps to the rear equipment and performing initial Crushing reduces the volume of the coal block, ...

Embodiment 2

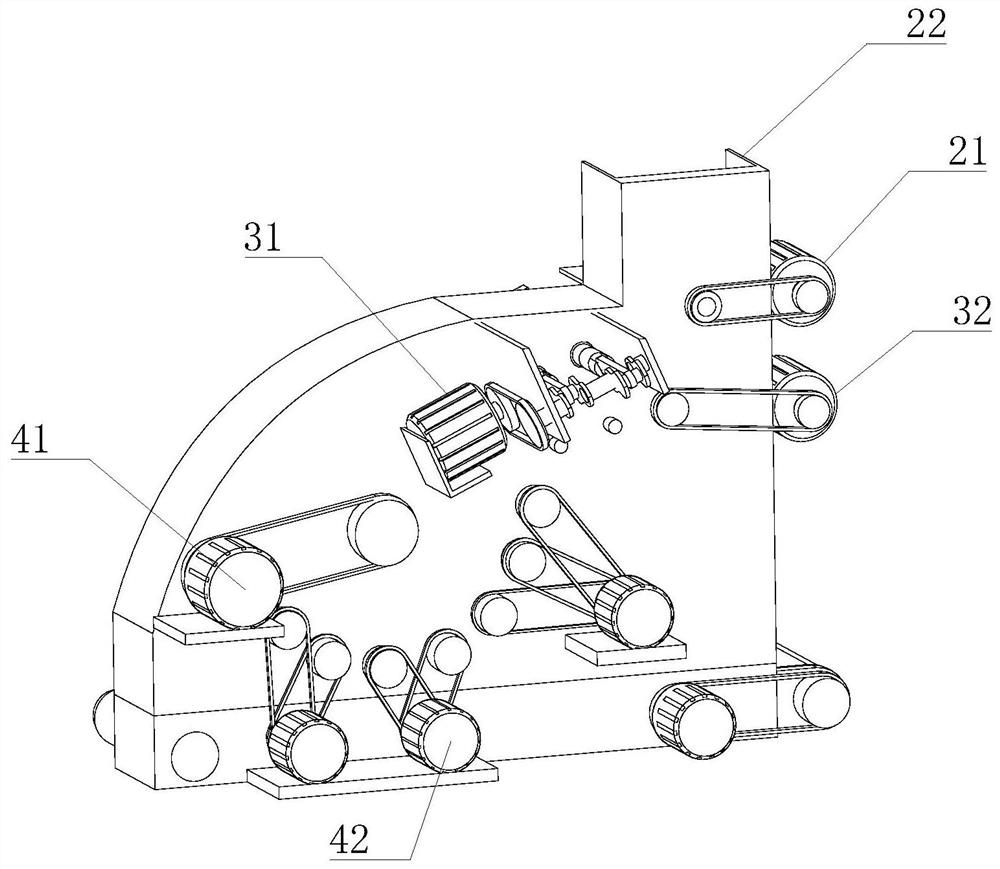

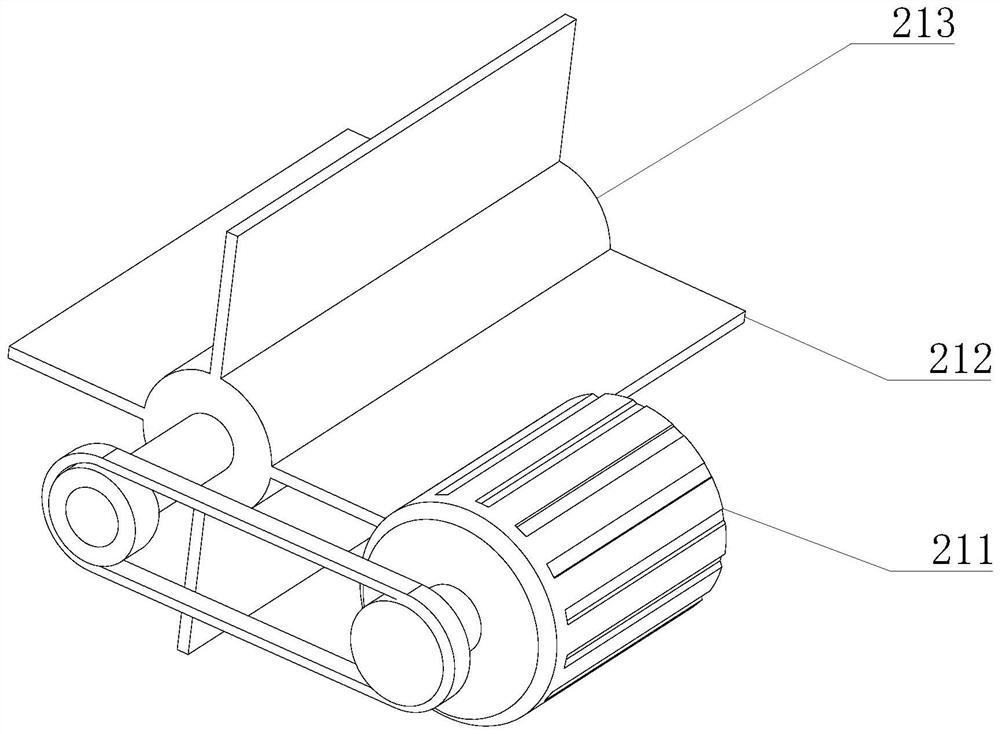

[0058] like Figure 1-16 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the iron removing device 2 includes a rotating iron removing device 21 and a filtering device 22, and the rotating iron removing device 21 is fixedly installed at the left end inside the cabinet 1 Below the feed inlet, the filter device 22 is fixedly installed inside the cabinet 1 and below the rotary iron removal device 21. The rotary iron removal device 21 includes a rotating motor 211, which is fixedly installed on the outer surface of the left side of the cabinet 1, and the rotating motor 211 A fixed shaft 213 is connected by a belt, and the fixed shaft 213 is movably installed on the rear wall of the cabinet 1. The outer surface of the fixed shaft 213 is fixedly equipped with iron removing plates 212, and the iron removing plates 212 are distributed in a circular array around the fixed shaft 213, filtering The device 22 includes a filter plate ...

Embodiment 3

[0060] like Figure 1-16 As shown, on the basis of Example 1, the present invention provides a technical solution: preferably, the primary screening and crushing device 3 includes a primary crushing device 31 and a transmission device 32, and the primary crushing device 31 is fixedly installed in the cabinet 1 On the front and rear surfaces, the transmission device 32 is fixedly installed inside the cabinet 1 and below the primary crushing device 31. The primary crushing device 31 includes a primary crushing motor 311, which is fixedly installed on the upper surface of the motor frame 11. The motor 311 is connected to the crankshaft 312 through a belt, and the internal shaft of the crankshaft 312 is movably connected to a connecting rod 313, and the other end of the connecting rod 313 is movably connected to a propulsion column 314, and the propulsion column 314 is movably connected to a sleeve 315, which is fixedly installed in the chassis 1. On the rear surface, a square gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com