Steam stripping cooling equipment and method for regenerated catalyst

A technology for regenerating catalysts and cooling equipment, applied in chemical instruments and methods, catalyst regeneration/reactivation, physical/chemical process catalysts, etc., can solve problems such as difficult implementation, increase tank diameter, etc., achieve less equipment investment and reduce impurities content, the effect of reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

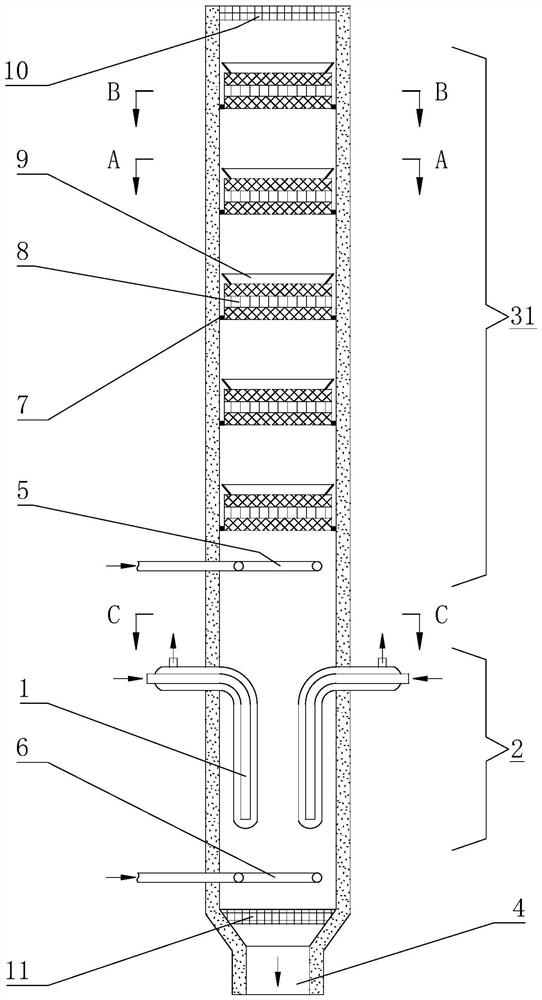

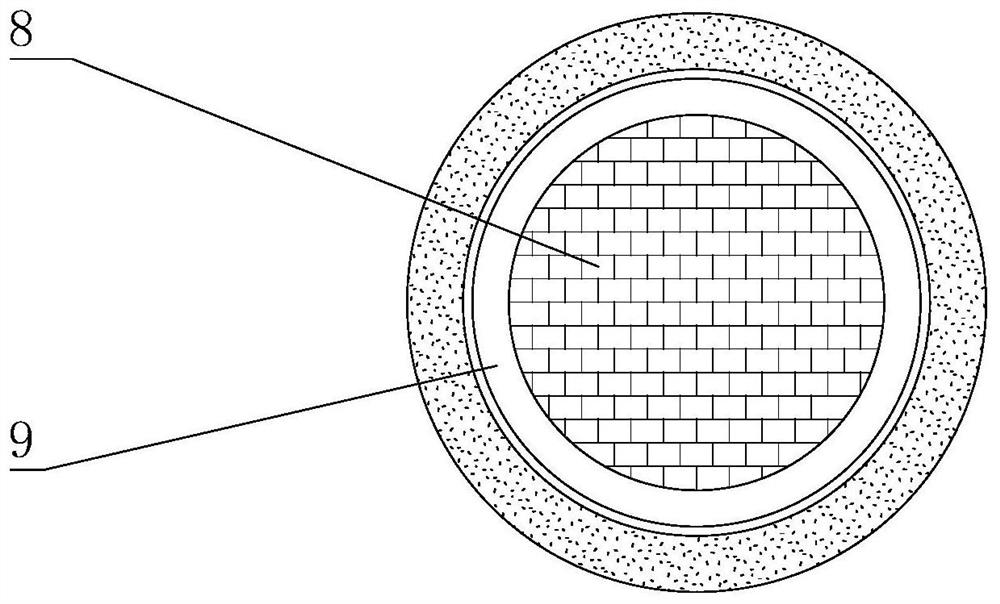

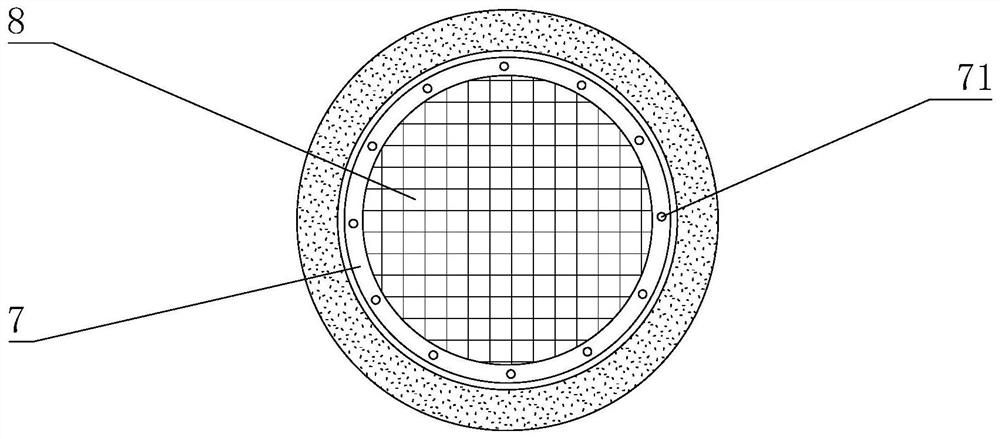

[0022] see figure 1 , figure 2 , image 3 with Figure 4 , The stripping and cooling equipment for the first regenerated catalyst of the present invention (abbreviated as equipment) includes a first stripping section 31 and a cooling section 2 arranged in the cylinder of the stripping and cooling equipment. The cylinder of the stripping cooling equipment is cylindrical, including a metal cylinder and a heat-insulating and wear-resistant lining. The catalyst inlet and the catalyst outlet 4 are respectively located at the top and bottom of the cylinder of the stripping cooling device. The catalyst inlet is connected with the regenerator, and the catalyst outlet 4 is connected with the regeneration conveying pipe through the regeneration standpipe and the regeneration slide valve. An inlet grid baffle 10 is provided at the catalyst inlet, and a bottom grid baffle 11 is provided above the catalyst outlet 4 to prevent the heat-insulating and wear-resistant lining of the cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com