Rapid polymerized hydrogel material as well as preparation method and application thereof

A hydrogel, fast technology, applied in medical science, bandages, etc., can solve the problems of restricting the development of biological tissue dressings, lack of anti-bacterial infection ability, complex production process, etc. fast healing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Take deionized water as solvent, take 10mL of deionized water, add 0.005mol of NaHCO 3 , stir well. Then add 0.01g of sodium carboxymethylcellulose and stir thoroughly; after the solution is completely clarified, add 0.08g of glucose again and stir evenly to obtain solution A; in 10mL of deionized water, add glacial acetic acid to make the concentration of glacial acetic acid reach 0.1mol / L, stir well and then add 0.04g chitosan, stir well to solution B. The two solutions of solution A and B were mixed uniformly at 37°C at a volume ratio of 1:1, and no gel was formed after 10s.

Embodiment 2

[0041] Take deionized water as solvent, take 10mL of deionized water, add 0.005mol of NaHCO 3 , stir well. Then add 0.1g of sodium carboxymethylcellulose, stir well, add 0.08g of glucose again after the solution is completely clarified, and stir evenly to obtain solution A; in 10mL of deionized water, add glacial acetic acid to make the concentration of glacial acetic acid reach 0.1mol / L, stir well and then add 0.04g chitosan, stir well to solution B. The two solutions of solution A and B were mixed uniformly at 37°C at a volume ratio of 1:1. After 10 seconds, the sodium carboxymethylcellulose solution was layered, and the layer was still layered after thorough stirring. The two solutions could not form a gel after mixing.

Embodiment 3

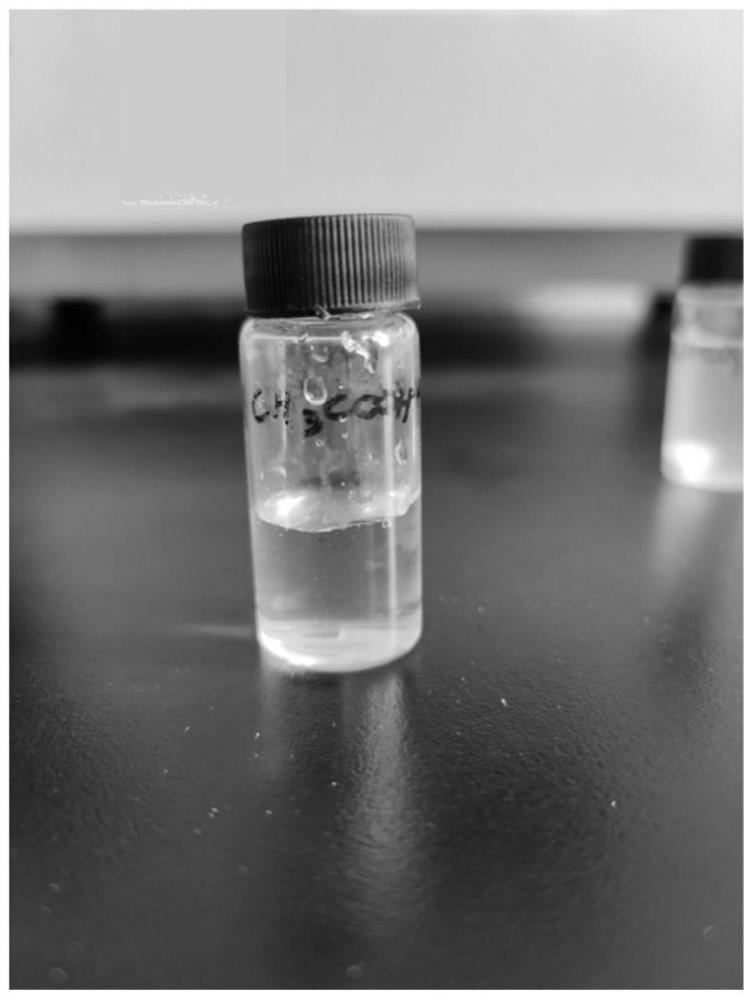

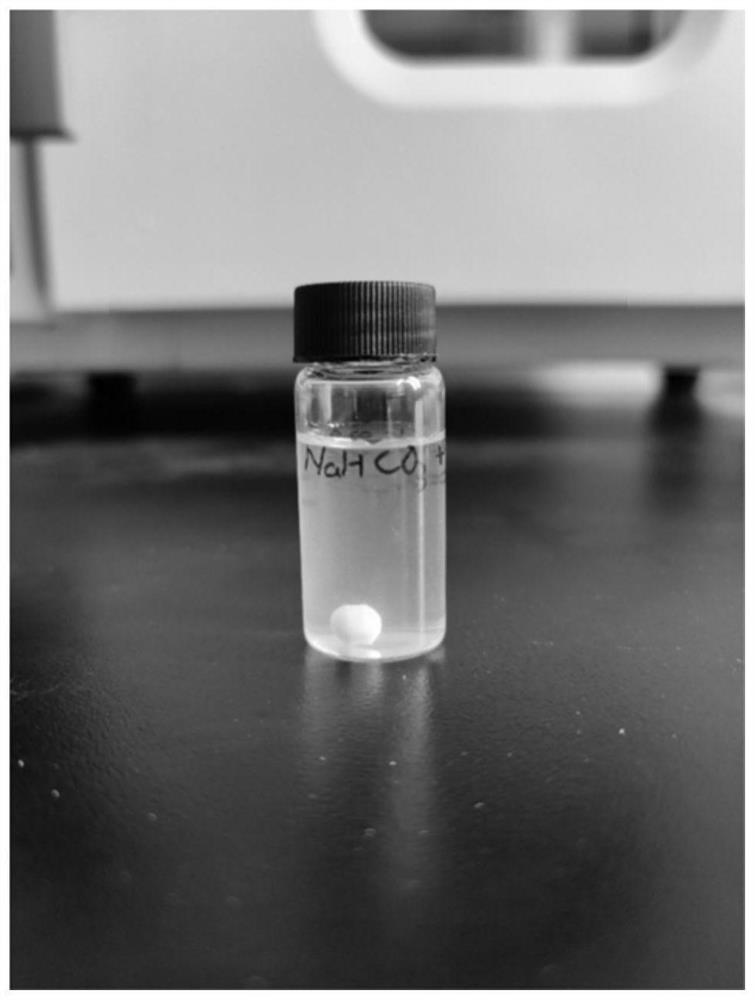

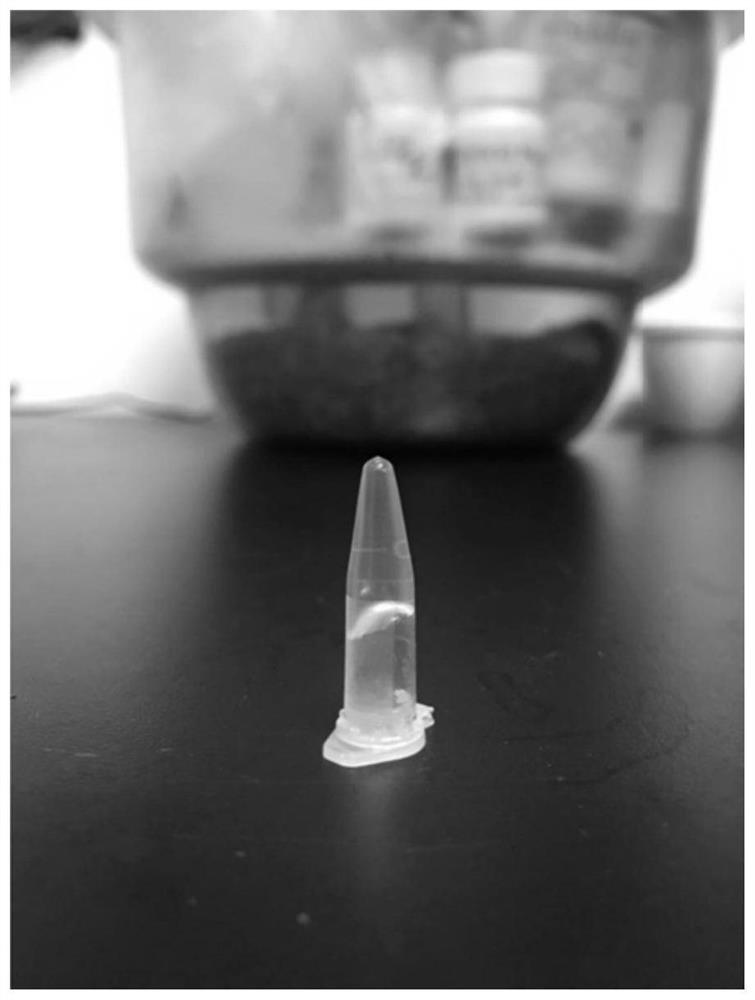

[0043] Take deionized water as solvent, take 10mL of deionized water, add 0.005mol of NaHCO 3 , stir fully; then add 0.05g of sodium carboxymethyl cellulose, and stir fully; after the solution is completely clarified, add 0.08g of glucose again, and stir evenly to obtain solution A; in 10mL deionized water, add glacial acetic acid to make the solution glacial acetic acid When the concentration reaches 0.1mol / L, stir evenly and then add 0.04g chitosan, stir evenly to get solution B. The two solutions of solution A and B were mixed uniformly at 37°C at a volume ratio of 1:1, and a gel was formed after 10 seconds. Such as Figure 1-3 As shown, chitosan has been completely dissolved in glacial acetic acid solution, and there is no layered solution to mix evenly; each component of sodium carboxymethyl cellulose, glucose, and sodium bicarbonate solution has been completely dissolved to form a uniform and stable colloidal solution; Cross-linking occurred after mixing the two soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com