Aerosol generating assembly and aerosol generating system

An aerosol generation and aerosol technology, which is applied to tobacco and other directions, can solve the problems of low atomization effect of aerosol generation substrates and inability to identify aerosol generation substrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

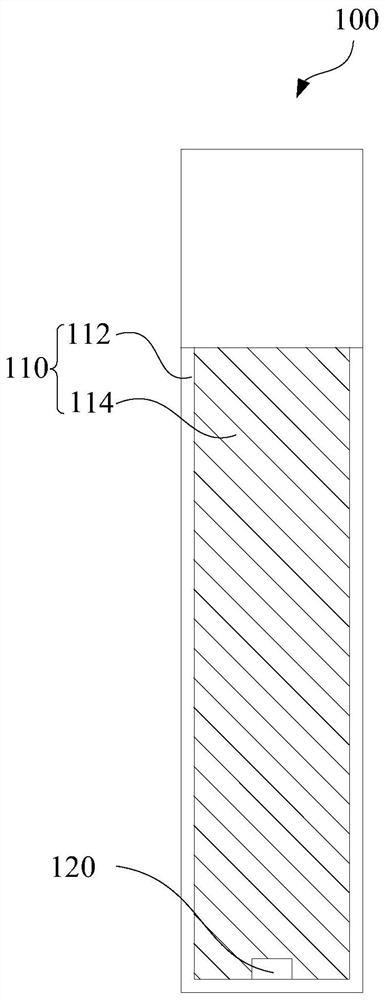

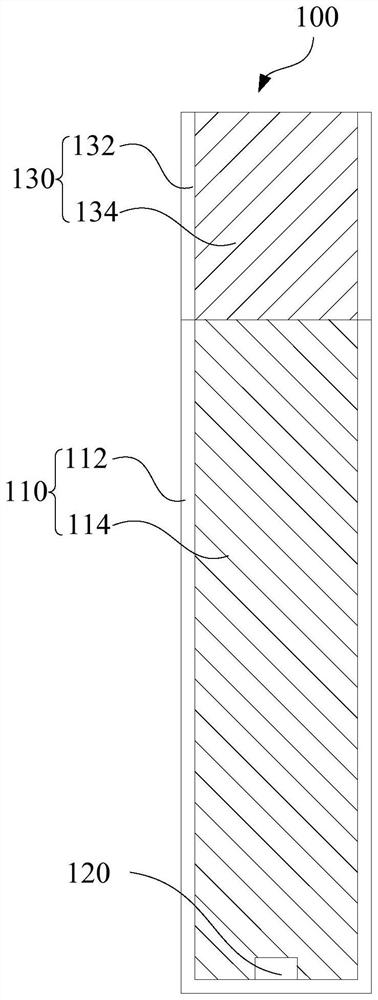

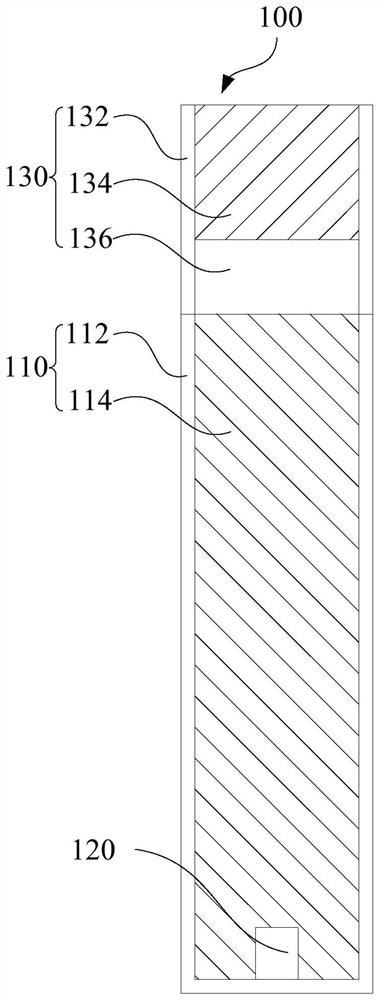

[0087] Such as figure 1 As shown, the first embodiment of the present application provides an aerosol generating assembly 100 , including: an aerosol generating substrate segment 110 and an identification member 120 .

[0088] Wherein, the aerosol-generating substrate segment 110 includes a first packaging layer 112 and an aerosol-generating substrate 114, the first packaging layer 112 forms a hollow first cylinder, and the aerosol-generating substrate 114 is accommodated in the first cylinder;

[0089] The identification part 120 is fixed on the aerosol generating matrix segment 110, and the identification part 120 is made of a wave-transparent material.

[0090] The aerosol generating assembly 100 provided in the embodiment of the present application includes an aerosol generating substrate segment 110 and an identification member 120 . The aerosol-generating substrate section 110 includes a first packaging layer 112 and an aerosol-generating substrate 114 disposed in the f...

Embodiment 2

[0143] Such as figure 1 with Figure 10 As shown, the second embodiment of the present application provides an aerosol generating system 200 , including: an aerosol generating device 210 and an aerosol generating assembly 100 .

[0144] Wherein, the aerosol generating device 210 includes an atomization chamber and a microwave assembly 212, and the microwave assembly 212 is used to feed microwaves into the atomization chamber;

[0145] At least part of the aerosol generating assembly 100 is located in the atomization chamber, and the aerosol generating assembly 100 is selected as the aerosol generating assembly 100 in any of the above-mentioned embodiments.

[0146]The embodiment of the present application provides an aerosol generating system 200 , and the aerosol generating system 200 includes an aerosol generating device 210 and an aerosol generating assembly 100 . The aerosol generating device 210 includes an opening, an atomizing chamber and a microwave assembly 212, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com