High vegetable protein soy sauce and production method thereof

A plant protein and production method technology, applied in the field of soy sauce, can solve the problem of low plant protein content and achieve the effect of increasing plant protein content, rich protein content, and high nitrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

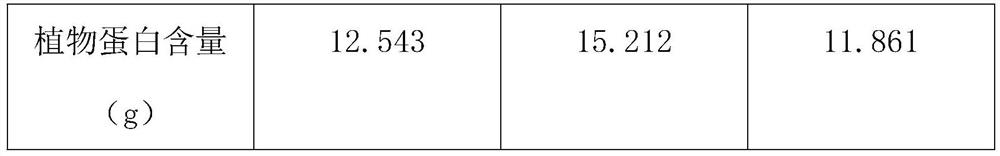

Embodiment 1

[0023] In the present embodiment, a kind of high vegetable protein soy sauce and production method thereof, concrete operation steps are:

[0024] S1: Raw material processing: dry and pulverize non-transgenic soybeans to 2-3 mm in diameter to make non-transgenic soybean flour, and dry and pulverize wheat until starch leaks out to make wheat flour;

[0025] S2: Preparation of koji species: Weigh 15 parts of non-transgenic soybean flour, 65 parts of wheat flour and 20 parts of corn steep liquor powder and mix them, add 100 parts of water and stir evenly, then pack and seal them in triangular flasks, divide Steam sterilize for 30 minutes after packaging, and add yeast extract while it is hot, and cultivate it in a constant temperature room at 28°C for 4 days;

[0026] S3: Preparation of seed koji: Weigh 82 parts of non-transgenic soybean flour, 8 parts of wheat flour and 10 parts of corn steep liquor powder and mix them as raw materials for preparation, add erythritol to water, a...

Embodiment 2

[0031] Different from Example 1, the specific operation steps are:

[0032] S1: Raw material processing: dry and pulverize non-transgenic soybeans to 2-3 mm in diameter to make non-transgenic soybean flour, and dry and pulverize wheat until starch leaks out to make wheat flour;

[0033] S2: Preparation of koji species: Weigh 15 parts of non-transgenic soybean flour, 65 parts of wheat flour and 20 parts of corn steep liquor powder and mix them, add 100 parts of water and stir evenly, then pack and seal them in triangular flasks, divide Steam sterilize for 30 minutes after packaging, and add yeast extract while it is hot, and cultivate it in a constant temperature room at 28°C for 4 days;

[0034] S3: Preparation of seed koji: Weigh 82 parts of non-genetically modified soybean flour, 9 parts of wheat flour and 9 parts of corn steep liquor powder and mix them as raw materials for preparation, add erythritol to water, and the weight ratio of water to erythritol is 98:2, and the p...

Embodiment 3

[0039] Different from Example 1, the specific operation steps are:

[0040] S1: Raw material processing: dry and pulverize non-transgenic soybeans to 2-3 mm in diameter to make non-transgenic soybean flour, and dry and pulverize wheat until starch leaks out to make wheat flour;

[0041] S2: Preparation of koji: Weigh 15 parts of non-genetically modified soybean flour, 70 parts of wheat flour and 15 parts of corn steep liquor powder and mix them, add 100 parts of water and stir evenly, then pack and seal them in triangular flasks, divide Steam sterilize for 30 minutes after packaging, and add yeast extract while it is hot, and cultivate it in a constant temperature room at 28°C for 4 days;

[0042] S3: Preparation of seed koji: Weigh 82 parts of non-transgenic soybean flour, 10 parts of wheat flour and 8 parts of corn steep liquor powder and mix them as raw materials for preparation, add erythritol to water, and the weight ratio of water to erythritol is 98:2, and the prepared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com