Gravity support for building construction

A technology of building construction and gravity, which is applied to buildings, building structures, and on-site preparation of building components, etc., can solve the problems of inability to vibration and shock absorption, poor equipment effect, and inability to effectively help buildings, so as to improve the use effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

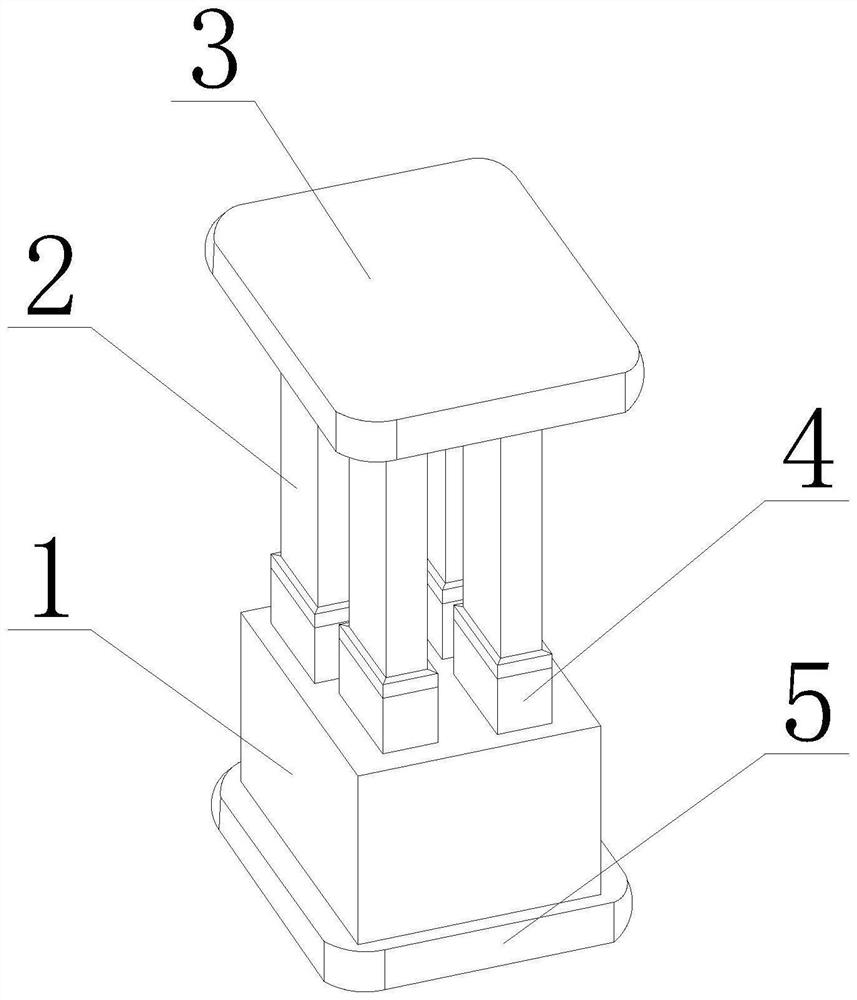

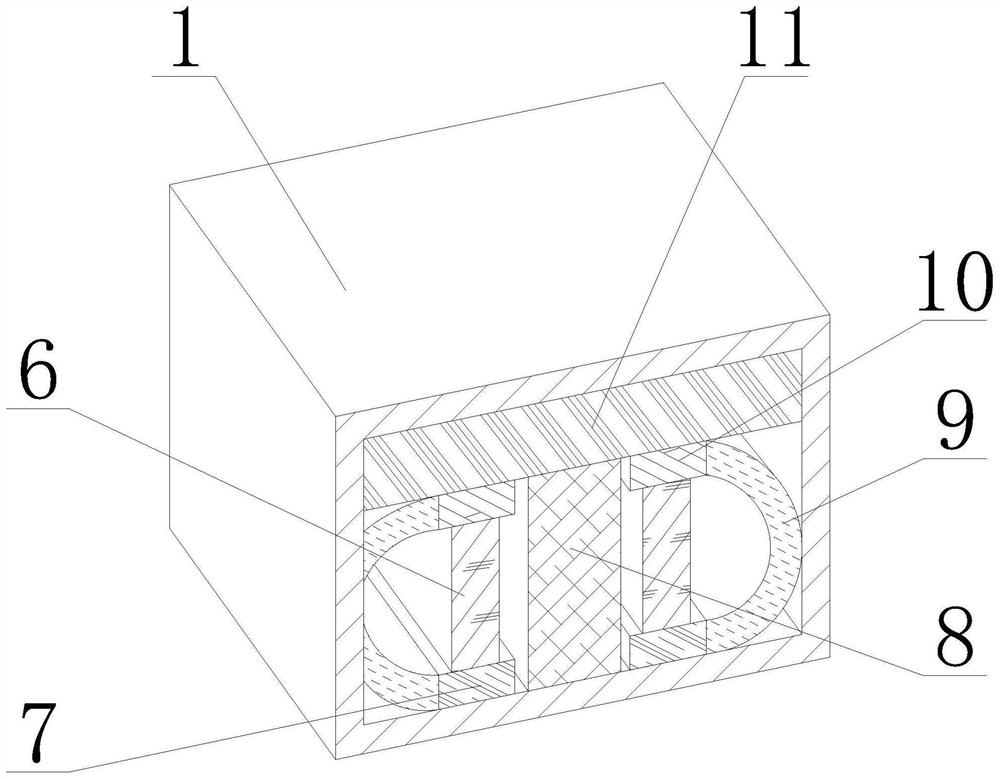

[0030] Such as Figure 1-Figure 5 As shown, the present invention provides a gravity support for building construction, comprising a gravity support main body 1, a telescopic support frame 2, a support top plate 3, a fixed support platform 4 and a main body base platform 5, and the top of the main body base platform 5 is fixedly installed on the gravity The bottom of the support main body 1, the bottom of the fixed support platform 4 is fixedly installed on the top of the gravity support main body 1, the surface of the telescopic support frame 2 is movably installed on the inner wall of the fixed support platform 4, and the bottom of the support top plate 3 is fixedly installed on the telescopic support frame 2, the bottom of the inner wall of the gravity support main body 1 is fixedly installed with a shock-absorbing fixed table 8, and the top of the inner wall of the gravity support main body 1 is fixedly installed with a solid main body support shaft 11, and the bottom of th...

Embodiment 2

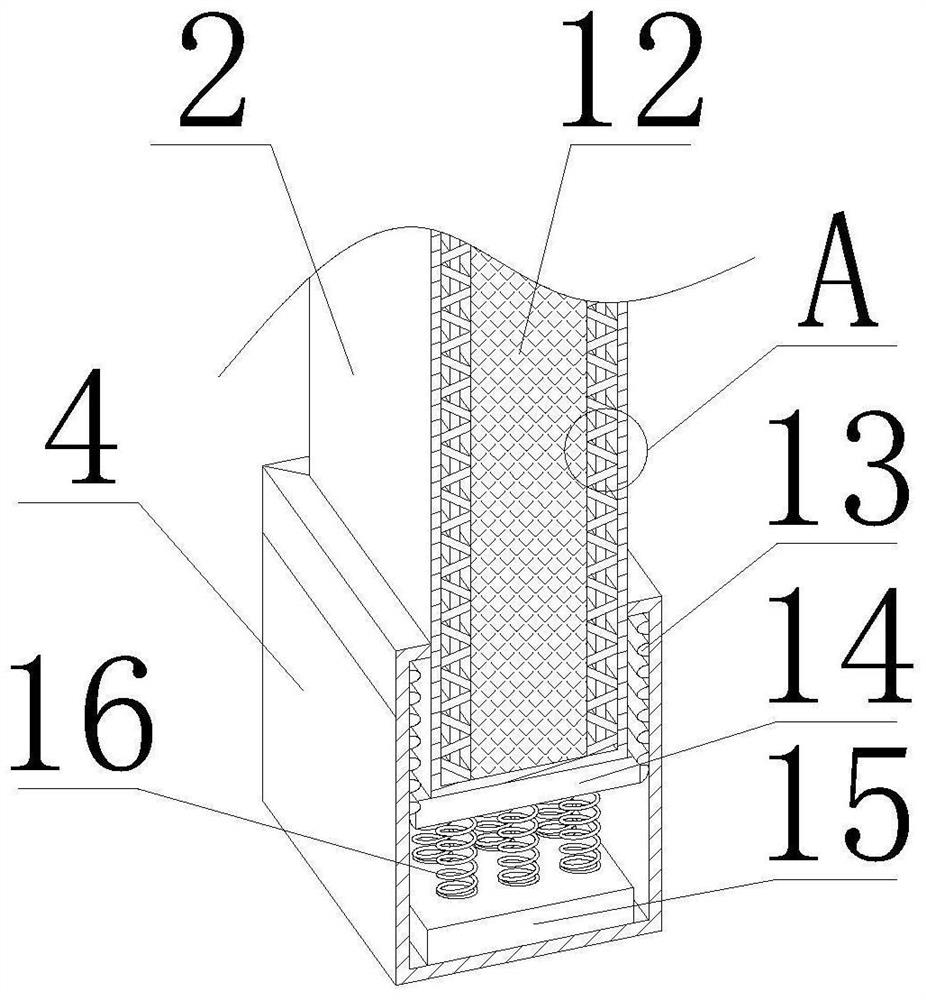

[0033] Such as Figure 1-5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the bottom of the solid body support shaft 11 and the left and right sides of the shock-absorbing fixed table 8 are fixedly installed with circular body pipe connectors 10, and the shock-absorbing semicircle One end of the body pipe 9 is fixedly installed on the outside of the round body pipe connector 10, the bottom of the round body pipe connector 10 is fixedly installed with a support transmission rod 6, and the bottom of the support transmission rod 6 is fixedly installed on the top of the transmission rod fixing table 7, telescopic The bottom of the inner wall of the support frame 2 is fixedly installed with a mixed cement center column 12, the upper and lower ends of the mixed cement center column 12 are fixedly installed on the inner wall of the telescopic support frame 2, and the bottom of the telescopic support frame 2 is fixedly installed with a lift...

Embodiment 3

[0036] Such as Figure 1-5 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the bottom end of the inner wall of the fixed support platform 4 is fixedly installed with a bottom connection fixing plate 15, and the top of the bottom connection fixing plate 15 is fixedly installed with The lifting connection spring 16, the top of the lifting connection spring 16 is fixedly installed on the bottom of the lifting bump baffle plate 14, the inner wall of the telescopic support frame 2 is fixedly installed with a connecting shaft steel bar 18, and the inner side of the connecting shaft steel bar 18 is fixedly installed on the mixing shaft. The cement central column 12, and the inner wall of the connecting shaft steel bar 18 are fixedly installed with a fixed shaft block 17, and the top of the inner wall of the supporting top plate 3 is fixedly installed with a gravity decompression plate 19, and the left and right sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com