Preparation method and application of snowflake-shaped crystallized ceramic glaze

A ceramic glaze and snowflake-shaped technology, which is applied in the field of preparation of snowflake-shaped devitrification ceramic glaze, can solve the problems of pollution, insufficient innovation, explosive environment, etc., and achieve the effect of simple firing equipment, low firing cost and low raw material price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

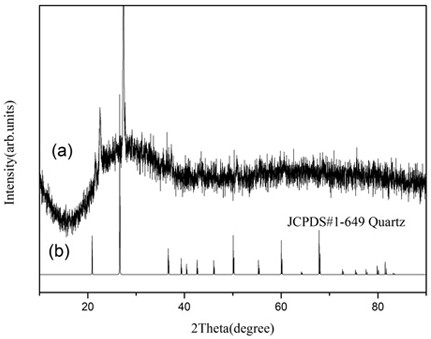

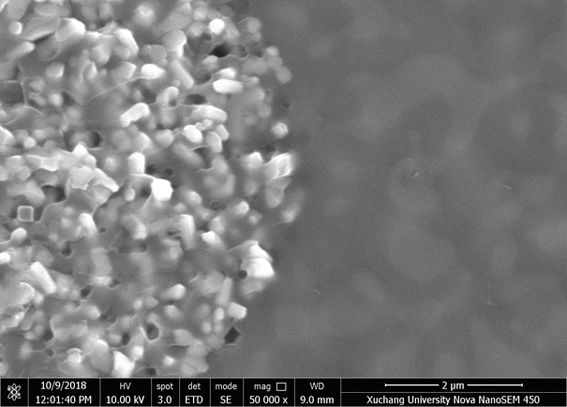

[0039] A preparation method and application of a snowflake-like devitrified ceramic glaze, comprising the following steps:

[0040] Step 1, egg shell calcined powder, barium carbonate, quartz, dredged bottom mud dry powder, nano-alumina powder are according to each mass ratio (egg shell calcined powder: barium carbonate: quartz: dredged bottom mud dry powder: nano-alumina powder=( 30: 25: 35: 3.0: 7) were weighed and prepared as JS glaze; among them, egg shell calcined powder was obtained by mechanically crushing egg shells and calcining at high temperature at 650°C for 1.5 h; dredging The dried sediment powder is obtained by passing the dredged sediment through a 200-mesh sieve and fully drying it in a blast drying oven. The drying temperature is 220 °C and the drying time is 5 h; the particle size of the nano-alumina powder is 100 nanometers .

[0041] Step 2. Mix JS glaze, water, and agate balls in a mass ratio of 1.0:1.6:1.6, and then use a planetary ball mill for ball mi...

Embodiment 2

[0047] A preparation method and application of a snowflake-like devitrified ceramic glaze, comprising the following steps:

[0048]Step 1, egg shell calcined powder, barium carbonate, quartz, dredged bottom mud dry powder, nano-alumina powder are according to each mass ratio (egg shell calcined powder: barium carbonate: quartz: dredged bottom mud dry powder: nano-alumina powder=( 40: 20: 30: 3.0: 7)) were weighed and prepared as JS glaze; among them, calcined egg shell powder was obtained by mechanically crushing egg shells and calcining at high temperature at a calcining temperature of 500°C and a holding time of 3 h; The dry powder of the dredged sediment is obtained by passing the dredged sediment through a 200-mesh sieve and fully drying it in a blast drying oven. The drying temperature is 180 °C and the drying time is 8 h; the particle size of the nano-alumina powder is 10 Nano.

[0049] Step 2. Mix JS glaze, water, and agate balls in a mass ratio of 1.0:1.6:1.6, and the...

Embodiment 3

[0055] A preparation method and application of a snowflake-like devitrified ceramic glaze, comprising the following steps:

[0056] Step 1, egg shell calcined powder, barium carbonate, quartz, dredged bottom mud dry powder, nano-alumina powder are according to each mass ratio (egg shell calcined powder: barium carbonate: quartz: dredged bottom mud dry powder: nano-alumina powder=( 35: 23: 35: 1.5: 5.5) were weighed and prepared as JS glaze; among them, egg shell calcined powder was obtained by mechanically crushing egg shells and calcining at high temperature at 600 °C for 2 h; dredging The dry sediment powder is obtained by passing the dredged sediment through a 200-mesh sieve and fully drying it in a blast drying oven. The drying temperature is 200 °C and the drying time is 7 h; the particle size of the nano-alumina powder is 40 nanometers .

[0057] Step 2. Mix JS glaze, water, and agate balls in a mass ratio of 1.0:1.6:1.6, and then use a planetary ball mill for ball mill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com