Organic solid waste wet oxidation treatment system and treatment process thereof

A wet oxidation and organic solid waste technology, which is applied in the direction of oxidation treatment of sludge, sludge treatment, sludge treatment, etc., can solve the problems of failure to make good use of pressure energy, control valve damage, poor heat transfer effect, etc. Achieve the effect of reducing the energy consumption of reaction sludge dehydration, saving sludge conditioning energy, and reducing the power consumption of injection pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

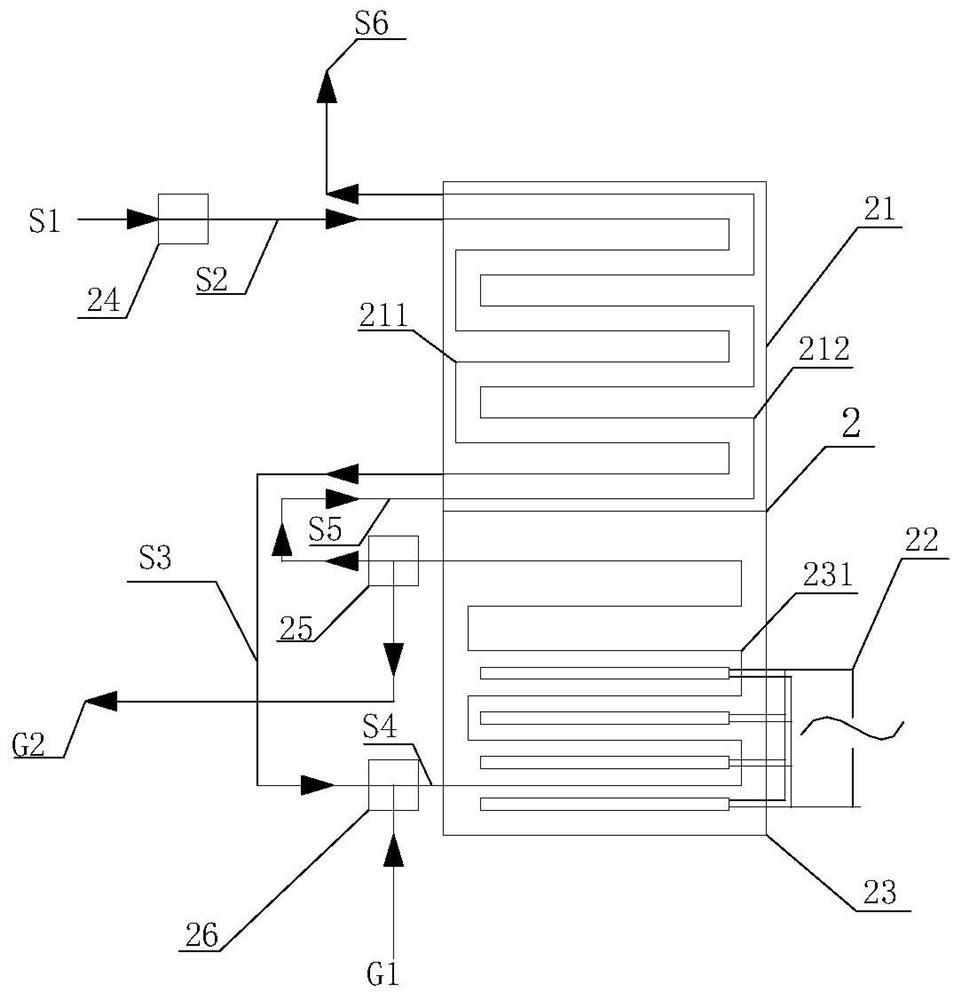

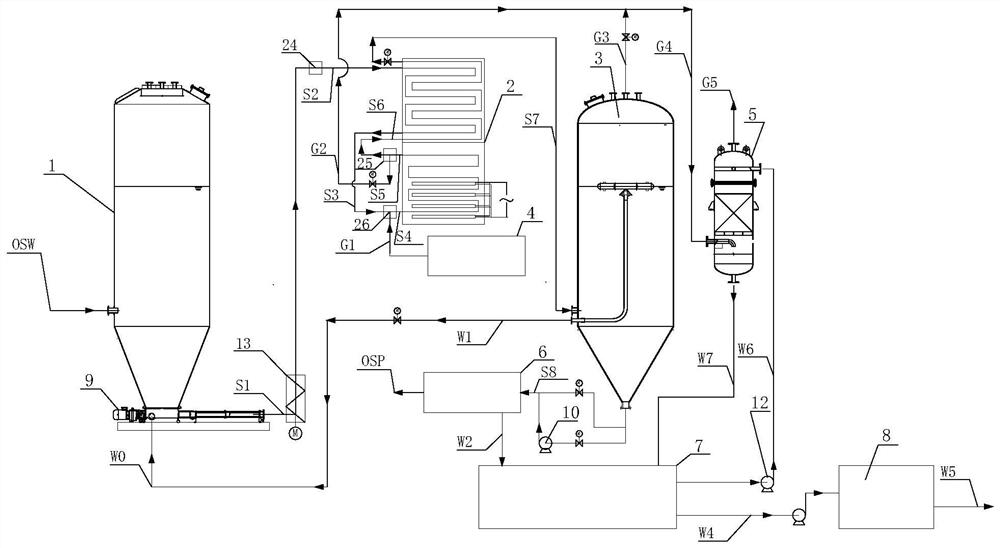

[0076] An organic solid waste wet oxidation treatment system of the present invention is as follows: figure 1 As shown, the main equipment includes sludge storage tank 1, pipeline self-heat exchange and reaction assembly assembly 2, reaction sludge pressure storage tank 3, oxygen-enriched air unit 4, reaction gas absorption tank 5, mechanical dehydration unit 6, sewage tank 7 and several pumping equipments, the pumping equipments include sludge pump 9, dewatering water pump 10, water injection pump 11, spraying water pump 12, in addition selectively set pulverizer 13 and sewage treatment unit 8 according to needs; Wherein, the pipeline type The self-heat exchange and reaction assembly assembly 2 includes a pipe-type sludge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com