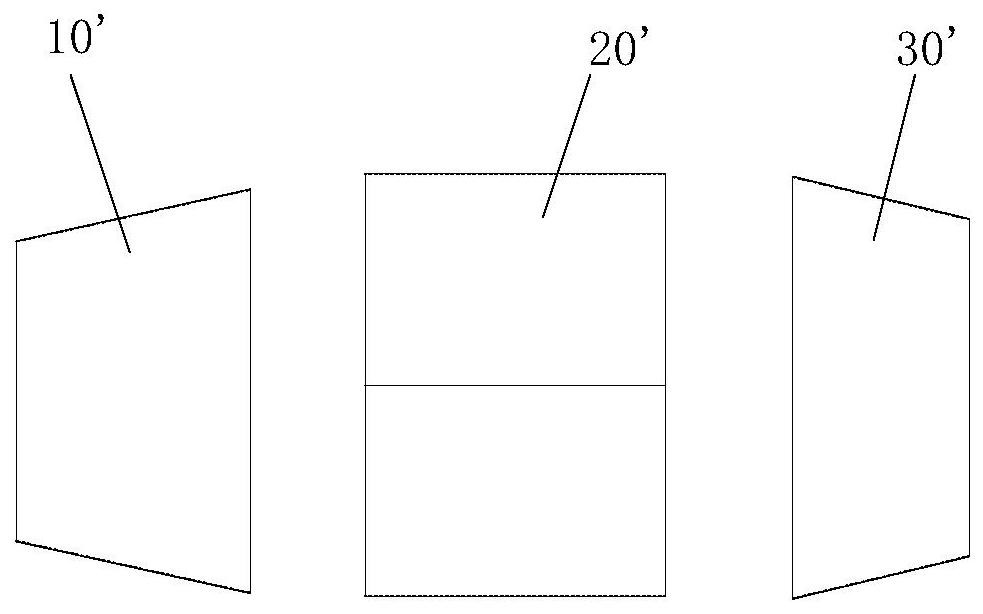

Automatic turnover device for shell rings of various concrete mixers

A technology of concrete mixer truck and turning device, which is applied in the directions of lifting device, hoisting device, transportation and packaging, etc., can solve the problems of low degree of automation, low efficiency, different length and width of cylinder sections, etc., and achieves good operability, High stability and easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

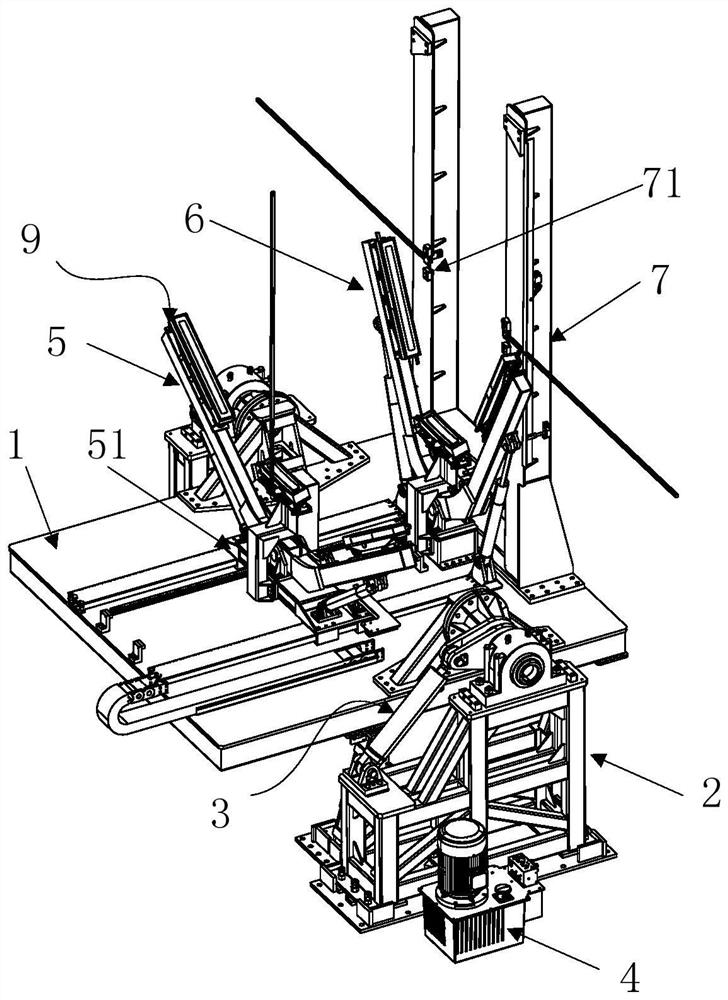

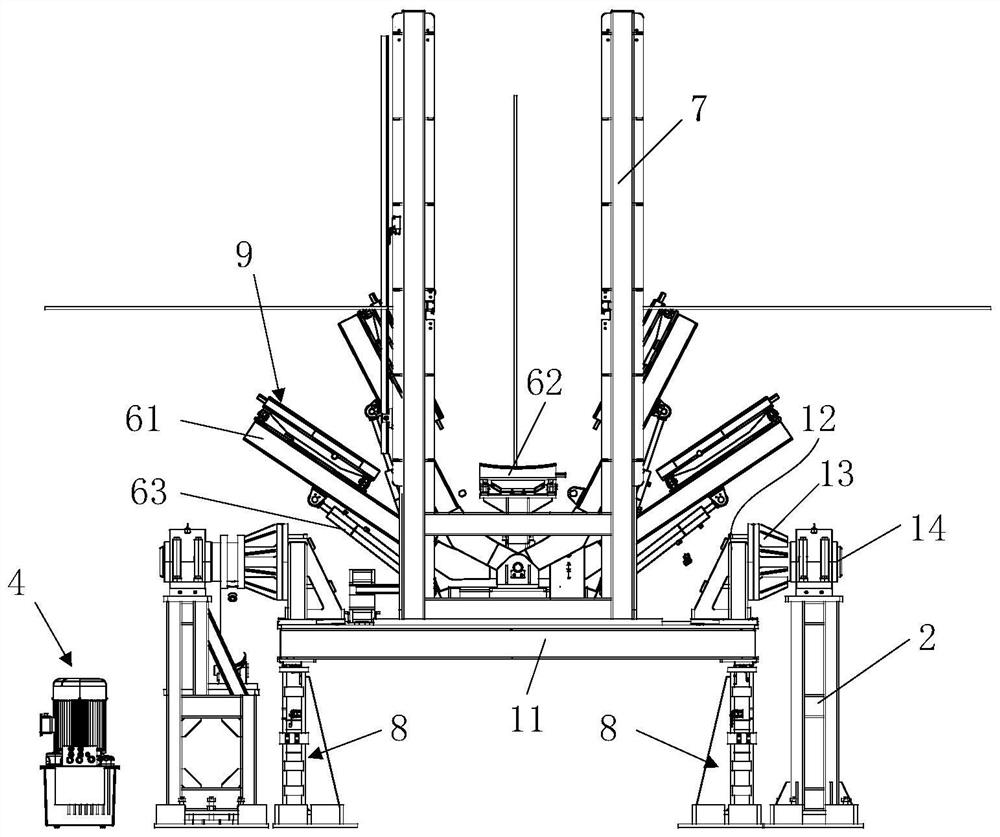

[0021] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0022] This equipment is mainly composed of turning platform 1, turning support 2, turning oil cylinder 3, hydraulic station 4, first supporting component 5, second supporting component 6, barrel end support 7, and platform positioning support 8.

[0023] The left and right sides of the turning platform 1 are supported on the turning support 2, wherein the turning platform 1 is mainly composed of a platform body 11, a hanger 12 arranged on the left and right sides of the platform body 11, a flange coupling cylinder 13, and a support shaft 14 Composition, the support shaft 14 is pivotally connected with the turning support 2 .

[0024] The flange connection cylinder 13 is connected to the hange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com