Micro-needle array with micro-pores, and preparation method thereof

A microneedle array and micropore technology, applied in the field of cosmetics, can solve the problems of limiting the rate and continuity of drug delivery, and the difficulty of making hollow microneedle polymer materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

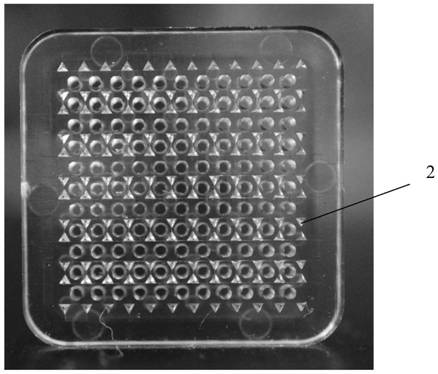

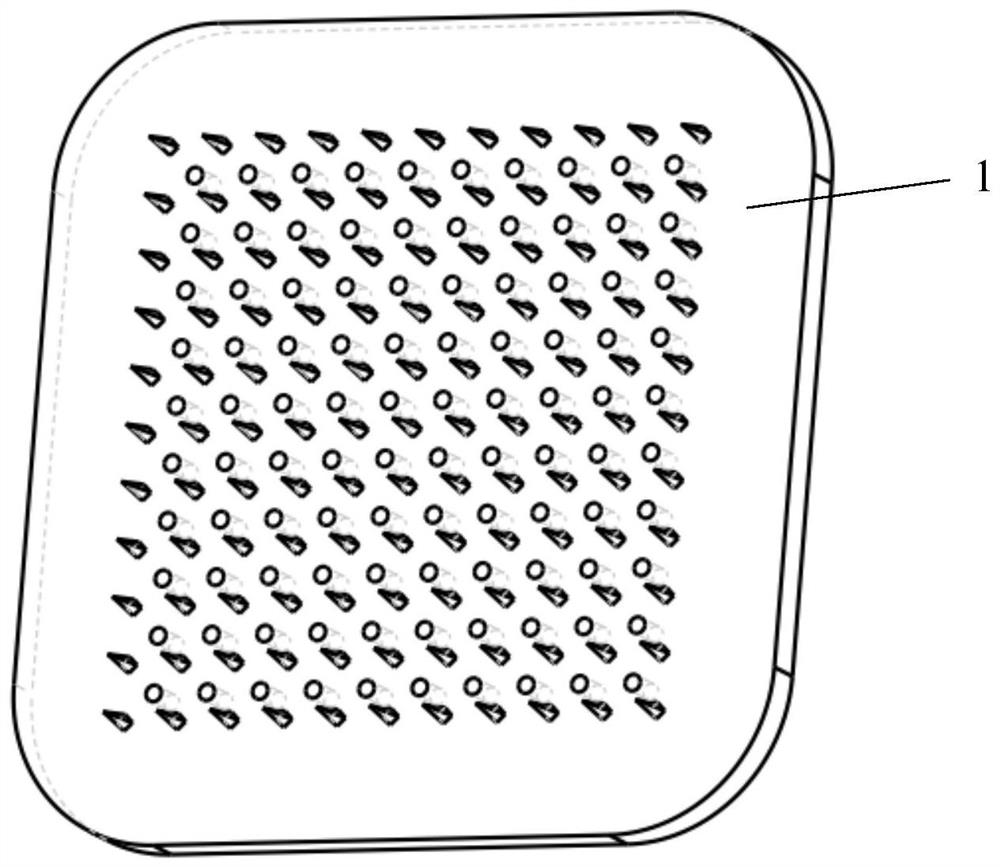

[0034] Fabrication of porous square microneedle arrays

[0035] a) Make a planarized base concave mold

[0036] Process the PCL polymer material with a laser to form a base die 42 with a flattened side 41 to form an upper mold 4, such as Figure 4 shown.

[0037] The base die is a square, and the side length of the square is 2 cm.

[0038] The height of the base die is 2 mm.

[0039] b) Etching to make a microneedle and microhole integrated mold

[0040] refer to Figure 4 , the selected laser model is: cnc-3020, staggered at intervals of 1 mm to form a square array of 11*11 microneedles and 10*10 microholes.

[0041] According to the requirements of the array, the laser is used to etch the microhole groove 43 on the upper mold at the corresponding position to prepare the microneedles; by controlling the laser, the microneedle array can be distributed in the entire array or at a specific position such as around the periphery of the array;

[0042] At the same time, the c...

Embodiment 2

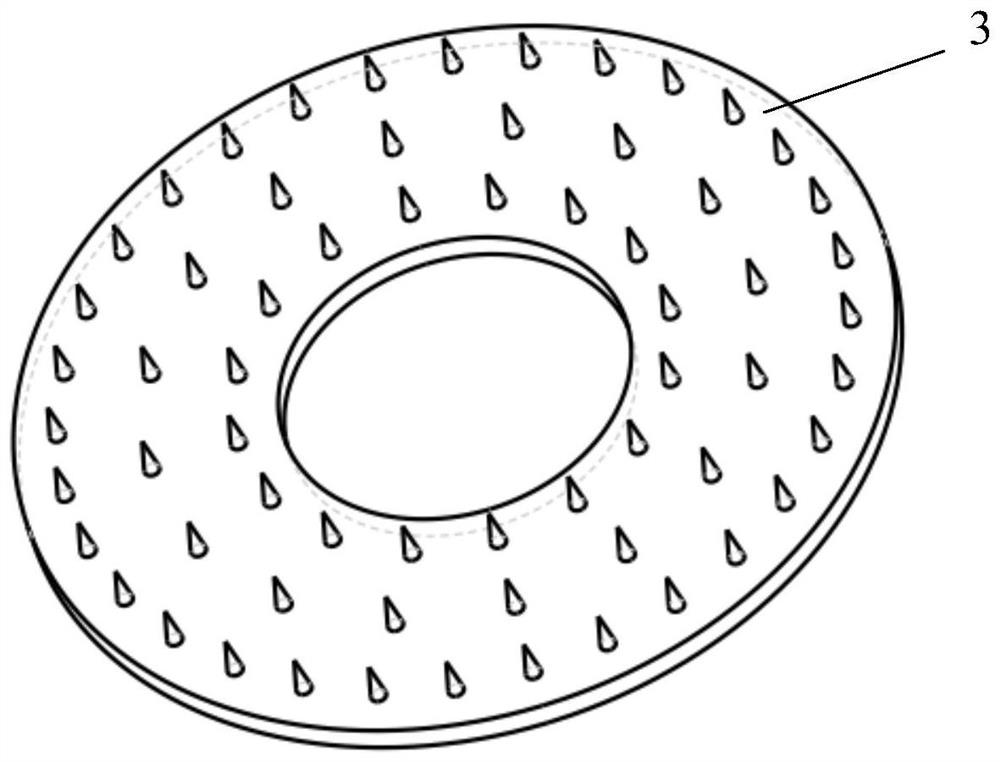

[0052] Fabrication of single-hole circular microneedle arrays

[0053] a) Make a planarized base concave mold

[0054] The PMA polymer material is processed with a laser to form a substrate cavity with flattened sides on the upper mold.

[0055]The base die of the upper mold is circular, and the diameter of the circle is 2cm.

[0056] The height of the base die is 2 mm.

[0057] b) Etching to make microneedle array mold

[0058] refer to image 3 , the selected laser model is: cnc-3020, and the three rings are arranged at equal intervals from the inside to the outside to form a circular array of 16, 16, and 32 microneedles.

[0059] According to the requirements of the array, the laser is used to etch the microhole groove on the upper mold at the corresponding position to prepare the microneedle; by controlling the laser, the microneedle array can be distributed in the entire array or at a specific position such as around the periphery of the array;

[0060] The etched up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

| Hole diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com