Mining suspension movable type intelligent grouting system

A grouting system and mobile technology, applied in mining equipment, mixers, wellbore linings, etc., can solve the problems of uncontrollable initial setting and final setting time, high labor intensity of operators, low transportation efficiency, etc., to achieve automation Control and refined management, reduce labor intensity of employees, and simplify the effect of grouting operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The application will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain related inventions, rather than to limit the invention. It should also be noted that, for ease of description, only parts related to the invention are shown in the drawings.

[0034] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present application will be described in detail below with reference to the accompanying drawings and embodiments.

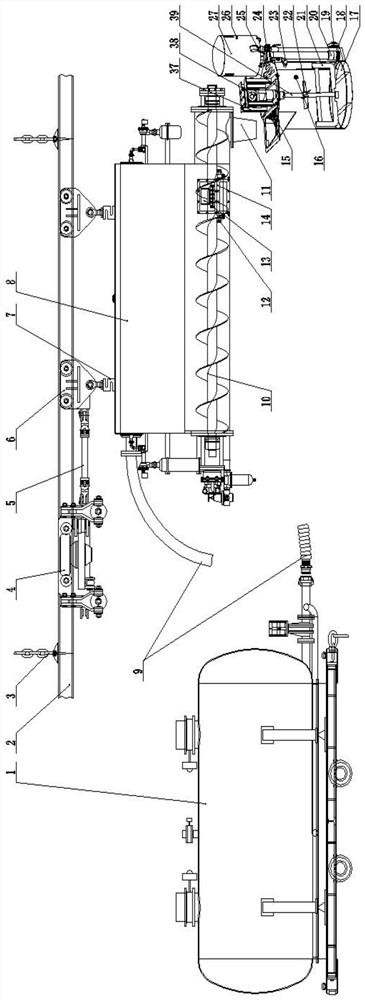

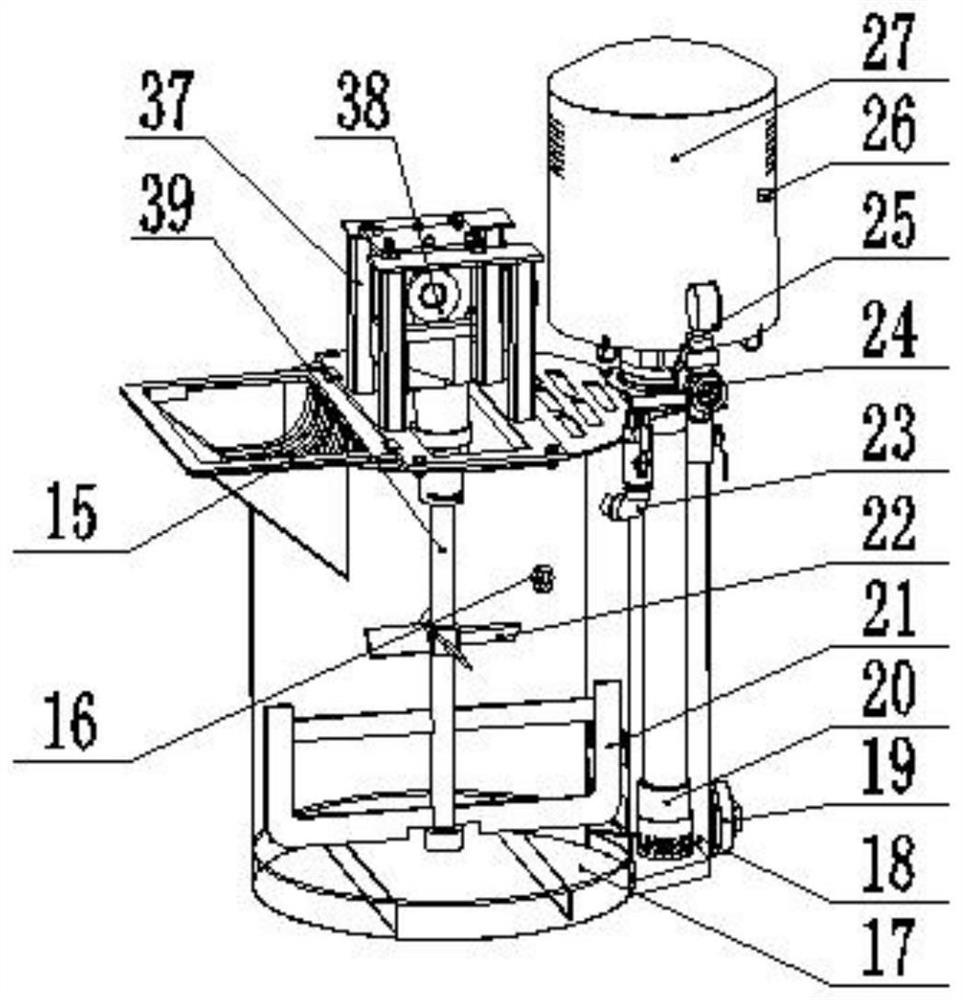

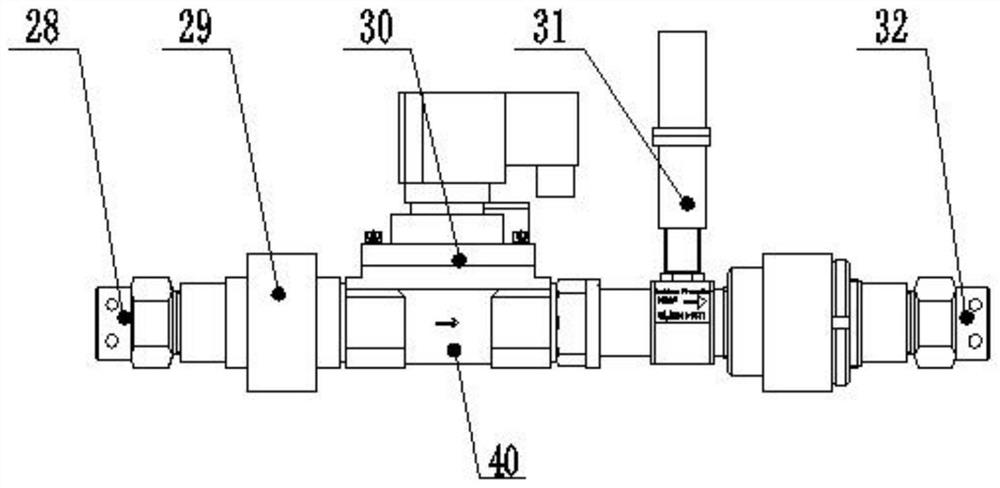

[0035] like figure 1 As shown, the present invention discloses a suspension mobile intelligent grouting system for mines, which can realize remote pneumatic conveying of powder materials, free movement and stop of the mobile silo along the track, quantitative feeding, automatic proportioning of wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com