Groove-jumping type grooving process for dry-method paved ceramic tiles

A ceramic tile and paving technology, which is applied in the field of dry paving tile-hopping slotting process, can solve the problems of high technical requirements of operators, uneven levels of workers, and reduced paving effect, etc., so as to achieve firm paving and reduce The effect of labor cost and shortening on-site construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

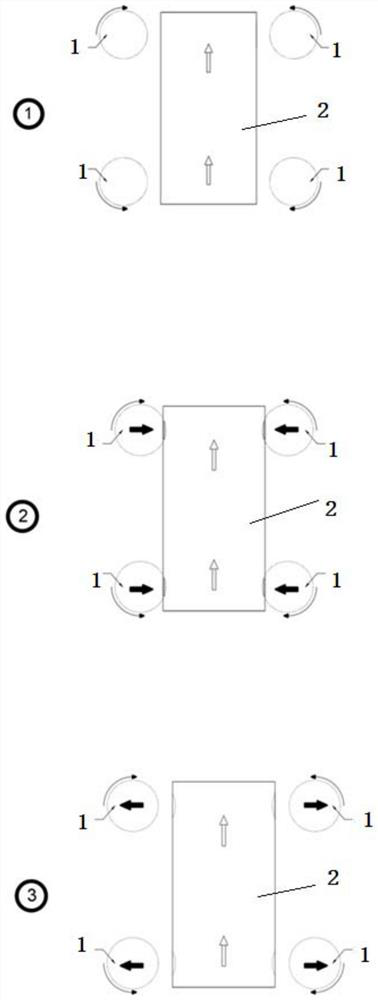

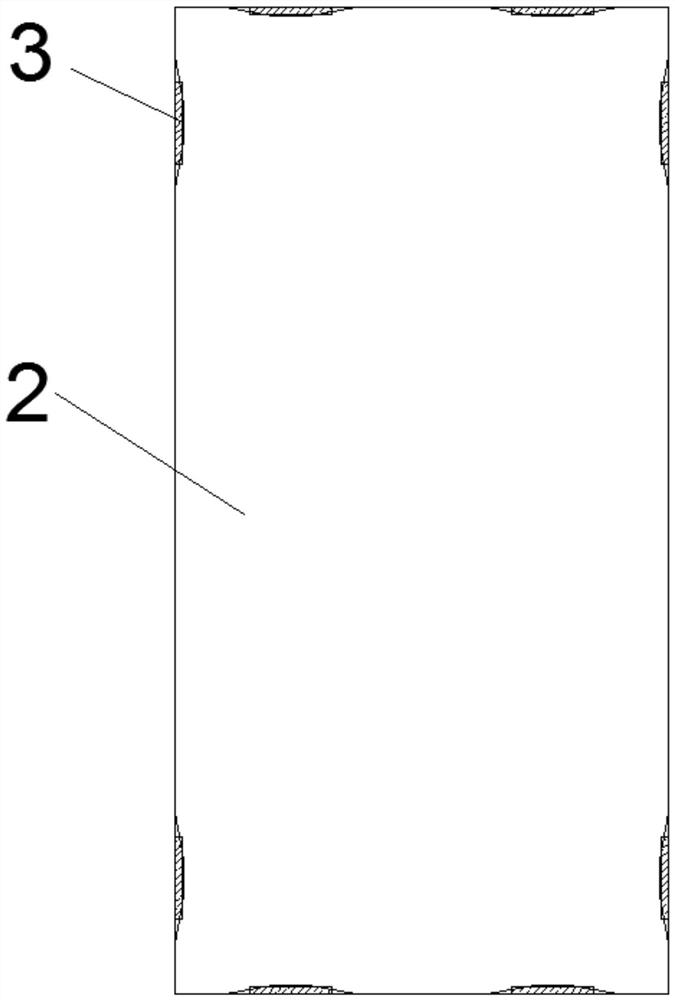

[0036] A dry method paving ceramic tile slot-hopping type slotting process, comprising the following steps:

[0037] S1, adjust the feeding width of the processing platform according to the tile width;

[0038] S2, start the processing platform, and start the tile conveying device;

[0039] S3, place the tiles to be grooved on the tile conveying device, and after conveying to the predetermined position, the pressure roller on the upper part of the tile conveying device presses and fixes the tiles, so as to prevent the tiles from swinging during processing and affect the processing accuracy;

[0040] S4, the tiles are conveyed to the processing position set by the processing platform, and the tiles stop conveying;

[0041] S5, the slotting motors set at intervals on both sides of the tile start, the water spray device above the tool starts to spray water on the surface of the tool continuously, so as to avoid the overheating of the tool during processing and reduce the service...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com