High-precision center fine-adjustment grinding machine tailstock

A high-precision, tailstock technology, which is applied to the parts of the grinding machine tool, the grinding workpiece support, the grinding drive device, etc., can solve the problems of large adjustment force, poor coaxiality, and large sliding friction. Reduced adjustment force, easy operation, and sensitive adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following description provides many different embodiments, or examples, for implementing various features of the invention. The elements and arrangements described in the following specific examples are only used to express the present invention in a concise manner, and are only used as examples rather than limiting the present invention.

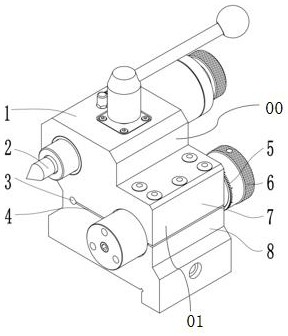

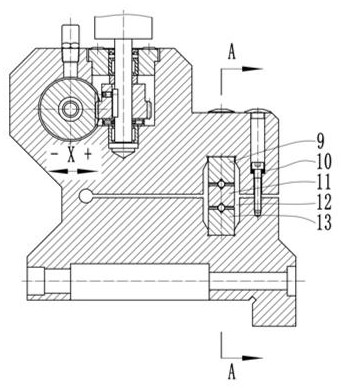

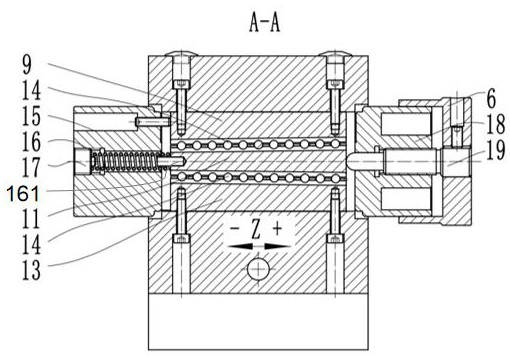

[0032] A high-precision fine-tuning grinder tailstock, such as Figure 1-2 As shown, the body 1 includes a first body 00 and a second body 01; the top 2 and other structures are arranged on the first body 00, which is a conventional structure in the field and will not be repeated here.

[0033] A through hole 3 and a horizontal slit 4 are provided in the first body 00; the through hole 3 is parallel to the axis of the tip; those skilled in the art can understand that the through hole is a hole penetrating from one end of the body 00 to the other end, such as figure 1 shown.

[0034] The horizontal slit 4 connects the through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com