Automatic welding tool for automobile grille decorating part

A technology for automatic welding and decorative parts, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor grid, poor welding consistency, and low welding efficiency, and achieve simple structure, convenient operation, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

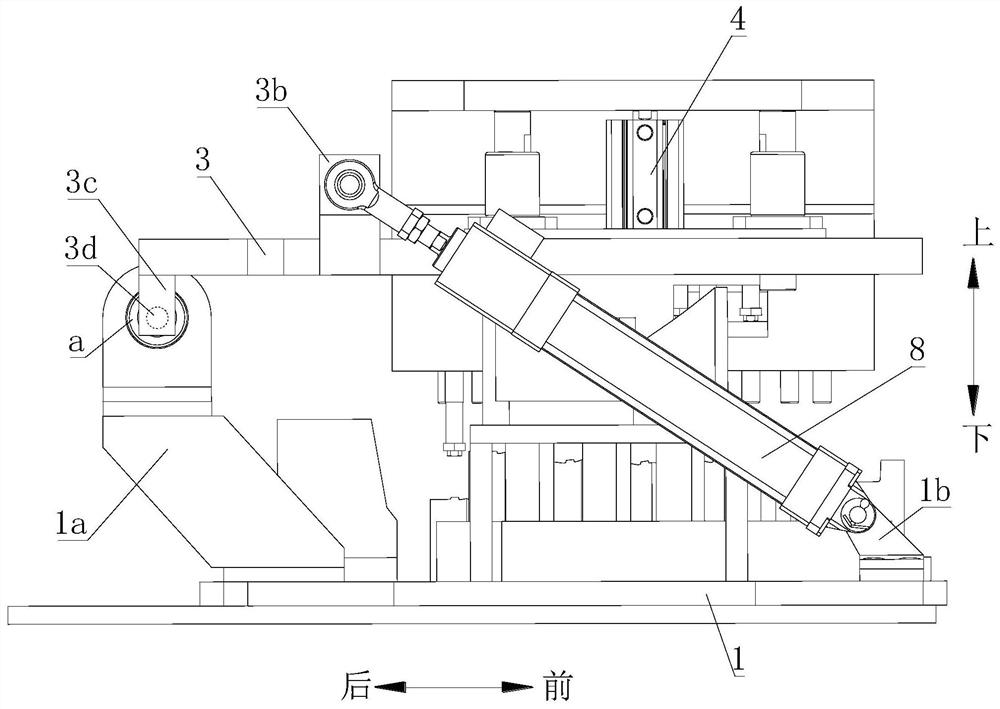

[0026] For the description of the directions "front, back, up, and down" in this embodiment, please refer to image 3 shown.

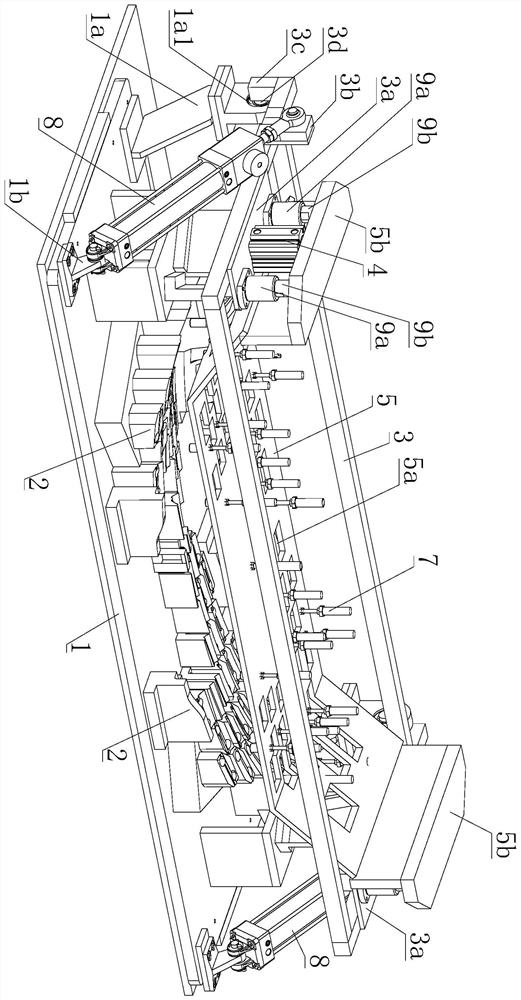

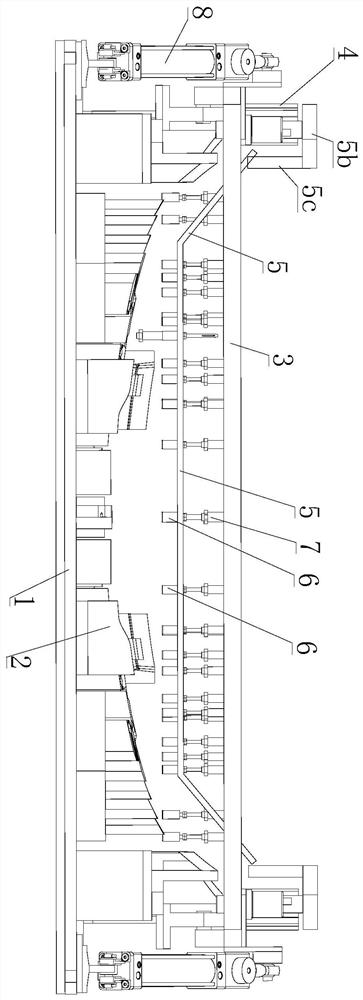

[0027] Such as figure 1 with 2 As shown, an automatic welding tool for automobile grille decoration, the tool includes a base 1, the upper surface of the base 1 is distributed with a number of protruding profiling blocks 2, the upper surface of each profiling block 2 and The outer contour of the grille A is adapted so that the grille A can be placed on the tooling smoothly. An upper mold frame 3 is movable above the base 1, and the assembly relationship between the two is: the rear end of the base 1 is provided with an upwardly extending bracket 1a, and the rear end of the upper mold frame 3 is rotatably assembled on the bracket 1a. And the third air cylinder 8 is installed between the upper die surrounding frame 3 and the base 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com