Waste gas treatment device for powder spraying production line

A technology for waste gas treatment device and production line, which is applied in gas treatment, dispersed particle filtration, membrane technology, etc., and can solve the problems of inconvenient replacement or cleaning of parts, poor filtration effect, and incomplete filtration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

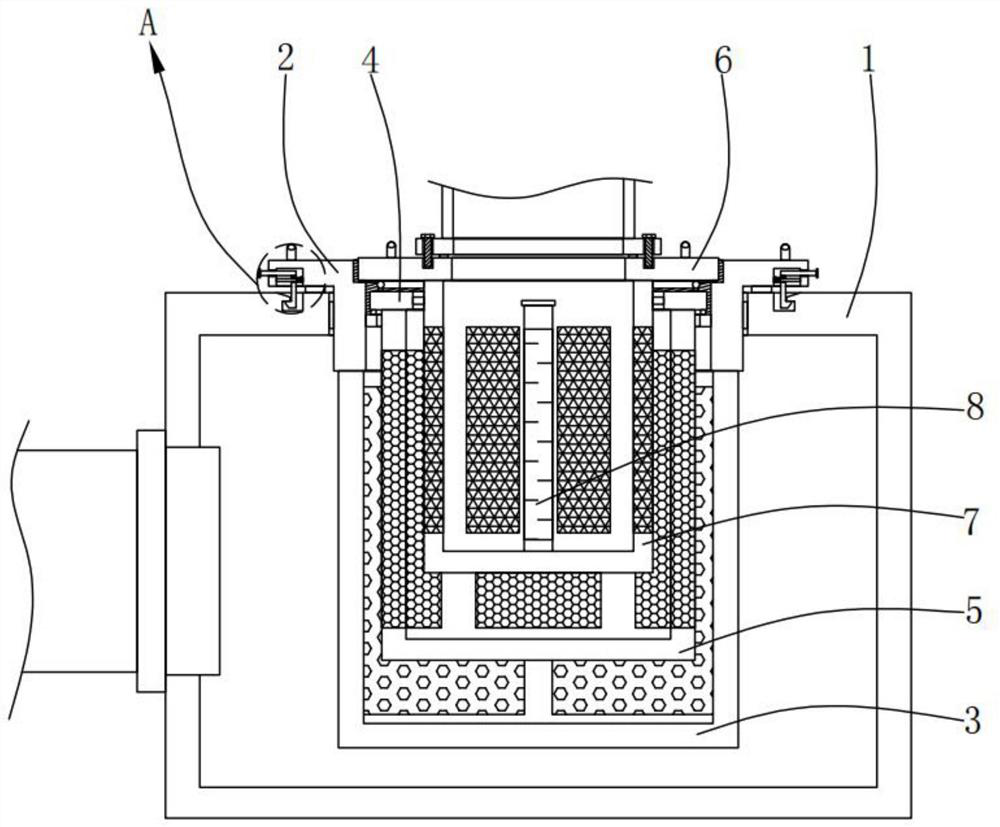

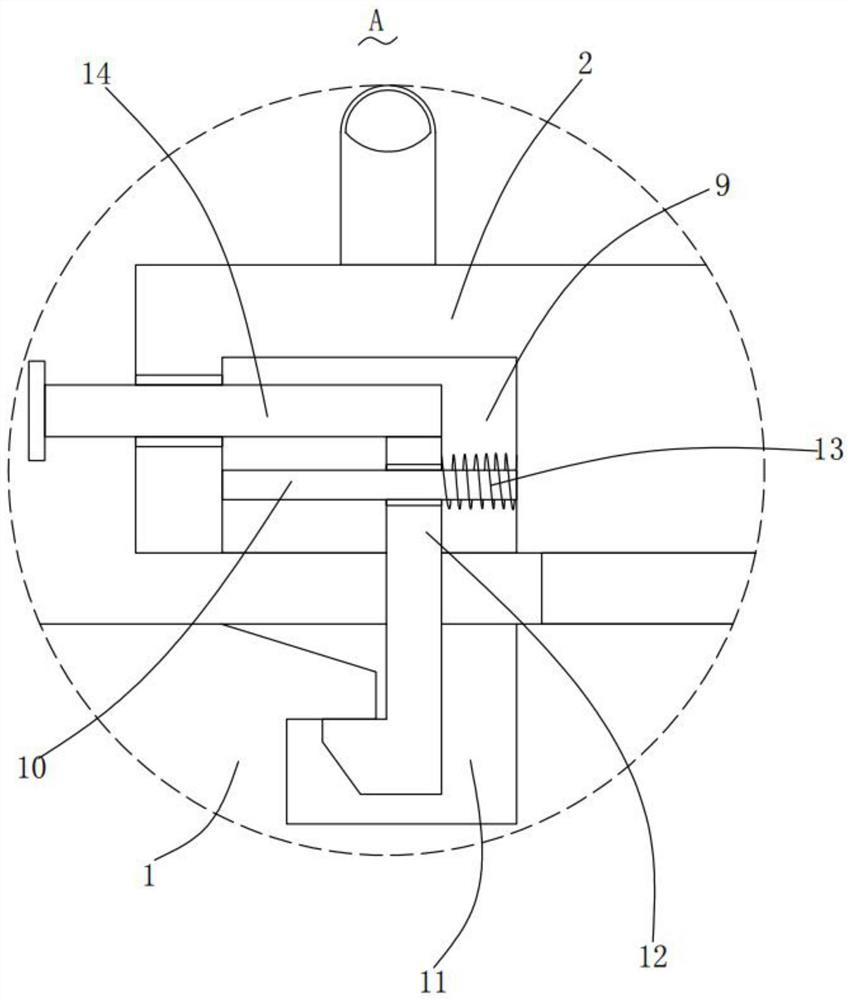

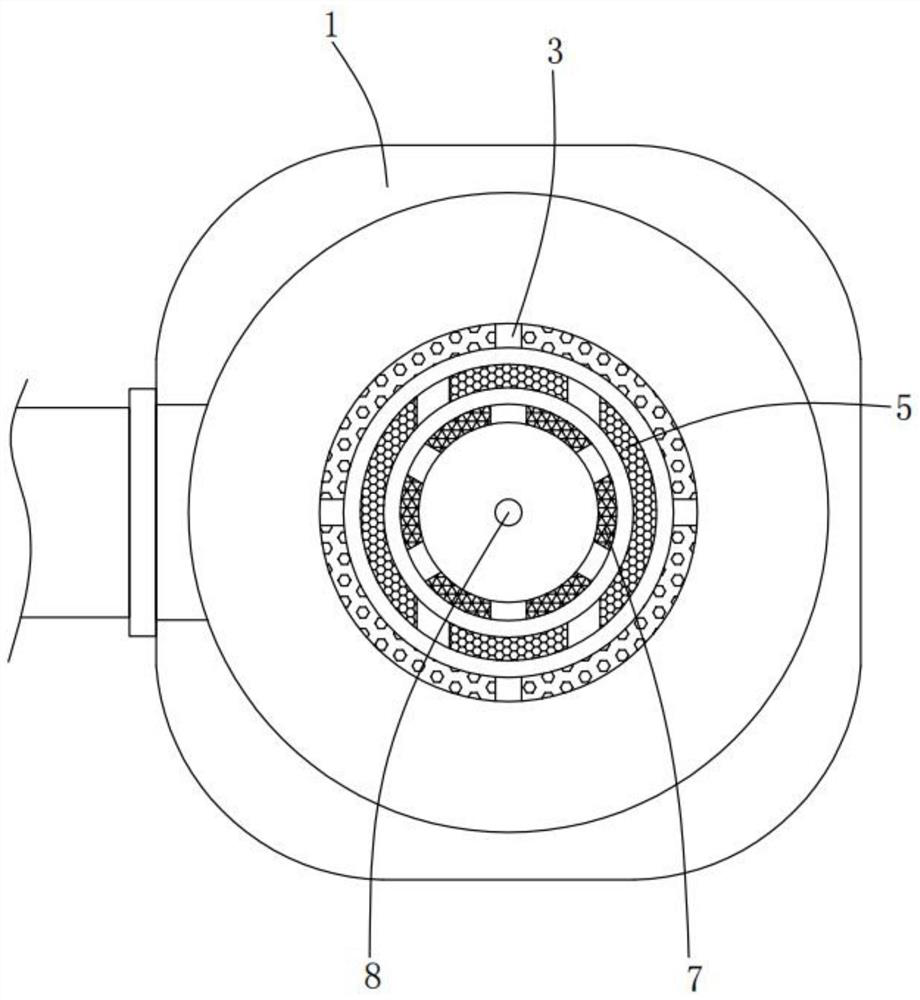

[0024] Please refer to Figure 1-3 , in the first embodiment of the present invention, the exhaust gas treatment device for the powder spraying production line includes: a housing 1; The bottom end of the bottom extends into the housing 1; the first filter barrel 3, the first filter barrel 3 is fixedly installed on the bottom of the screw 2; the first threaded ring 4, the first threaded ring 4 is installed in a sealed thread In the threaded member 2; the second filter barrel 5, the second filter barrel 5 is fixedly installed on the bottom of the first threaded ring 4; the second threaded ring 6, the second threaded ring 6 is installed in a sealed thread In the threaded part 2; the third filter bucket 7, the third filter bucket 7 is fixedly installed on the bottom of the second threaded ring 6; the high-strength ultraviolet lamp tube 8, the high-strength ultraviolet lamp tube 8 is fixedly installed on the The third filter barrel 7.

[0025] The threaded part 2 is symmetricall...

no. 2 example

[0035] Based on the waste gas treatment device for a powder spraying production line provided in the first embodiment of the present application, the second embodiment of the present application proposes another waste gas treatment device for a powder spraying production line. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0036] The second embodiment of the present invention will be further described below in conjunction with the drawings and implementation methods.

[0037] Please refer to Figure 4 , the exhaust gas treatment device for the powder spraying production line also includes an installation shell 15, the installation shell 15 is fixedly installed on the bottom of the housing 1, and the bottom of the first filter barrel 3 is rotatably installed with a rotating column 16, and the rotating column Two push rods 17 are sym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com