Distillers' soluble treatment method, table vinegar and preparation method of table vinegar

A processing method and technology for distiller's grains, applied in the field of distiller's grains processing method, vinegar and preparation thereof, can solve the problems of resource waste, environmental pollution and the like, and achieve the effect of prolonging the storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107] A method for processing distiller's grains, comprising the steps of:

[0108] 1) Soak the distiller's grains with alcohol, stir the distiller's grains every other day, and stop stirring after 2 weeks, so as to separate the chaff and cortex in the distiller's grains, and the remaining substances in the distiller's grains are mixed with the distiller's grains The leaching solvent forms an elution suspension;

[0109] 2) filtering and separating the chaff, the cortex and the eluting suspension in the distiller's grains;

[0110] 3) Ethanol in the eluted suspension is distilled off to obtain a distillation residue. Wherein, the weight percent of alcohol in the distillation residue is 5%.

Embodiment 2

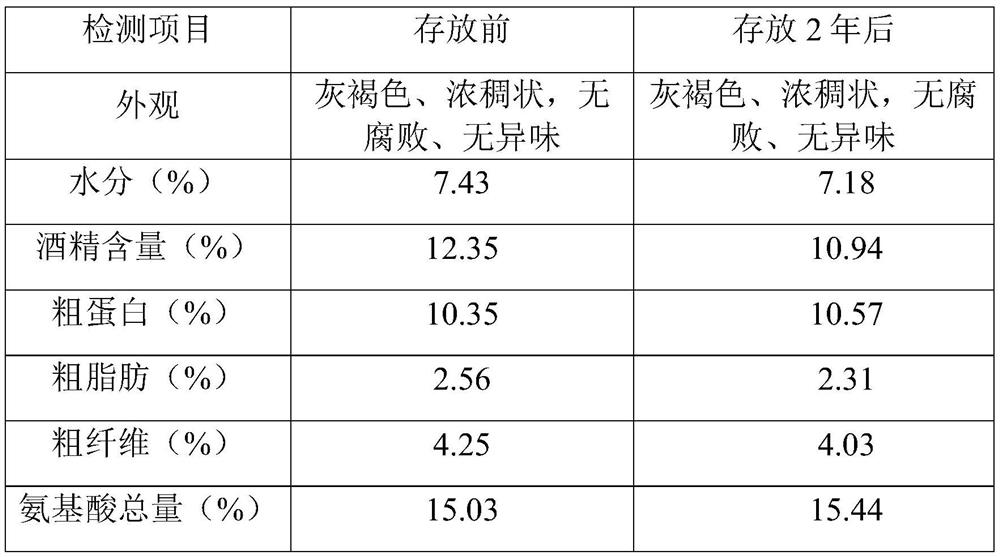

[0112] The distillation residue obtained in Example 1 was subjected to detection analysis and storage time experiment. Store the distillation residue in an airtight container at room temperature. The corresponding indicators were measured before storage and after 2 years of storage, and the results are shown in Table 1.

[0113] As can be seen from the results, after the distillation residue is preserved for 2 years, its appearance has no difference, and there is no spoilage; the nutrient content it contains has no obvious change, and it can be seen that the distiller's grains after the treatment of Example 1 can be stored for at least 2 years. Affect the later high-value utilization.

[0114] Table 1

[0115]

Embodiment 3

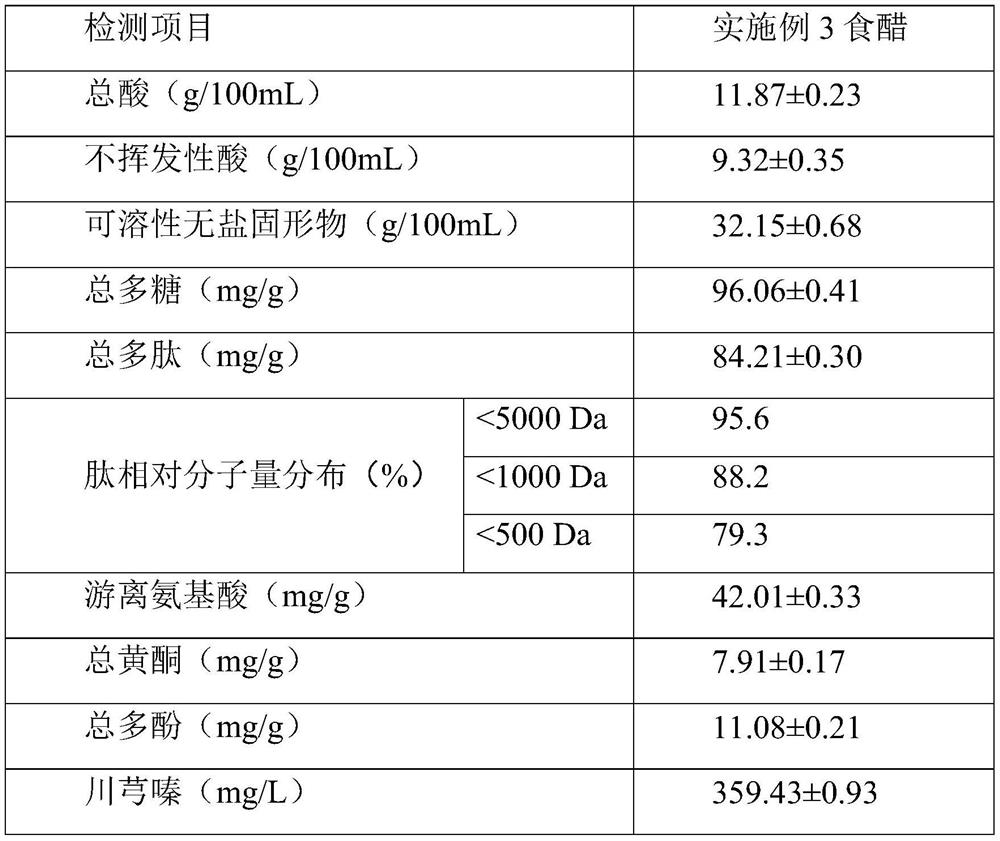

[0117] A method for preparing vinegar from distiller's grains, comprising the following steps:

[0118] The distillation residue and chaff obtained in Example 1 are placed in a fermentation device, the weight ratio of the distillation residue and the chaff is 1:0.4, and Jiuqu balsam ester vinegar with 150% of the weight of the distillation residue fermented for 6 to 8 days is added Vinegar unstrained spirits and 80% of the weight of the distillation residue are grain-processed skin substances, mixed evenly, and fermented for 12 days to obtain a fermented product;

[0119] Transfer the fermented product into a glass tank, compact and fill it up, tighten the lid with a sealing plug, and seal it with gypsum and glue to ensure a tight seal, and age the unstrained spirits for 180 days in an environment of 2°C to 25°C to obtain aged unstrained spirits product;

[0120] Take 50% of the aged unstrained spirits product and put it into a smoked unstrained spirits tank, heat it with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com