Attapulgite-containing water-based photocureable coating

A light-curing coating and attapulgite technology, applied in the coating field, can solve the problems of low hardness, wear resistance and poor gloss of the paint film, and achieve the effects of low cost, high adhesion and low equipment dependence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

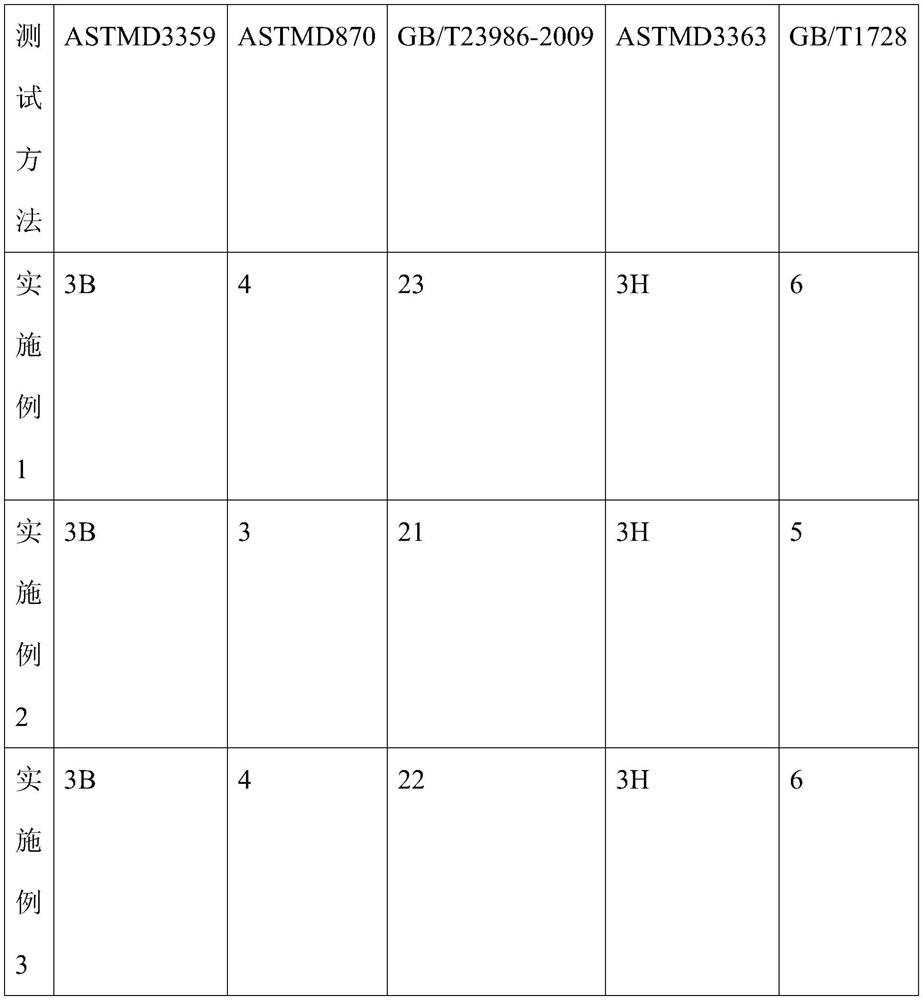

Embodiment 1

[0020] (1) Preparation of water-based prepolymer: Add 10 parts of hyperbranched water-based polyurethane acrylic resin and 10 parts of 4-toluene isocyanate into a three-necked bottle with a stirring device, and add 50 ml of high boiling point solvent hexamethylphosphorous triamide , feed inert gas or nitrogen, stir and react for 1 hour at 60 degrees Celsius, then add 5 parts of piperidine-1,4-dihydroxypropanesulfonic acid and 5 parts of 2,3-dihydroxypropyl methacrylate at 50 The water-based prepolymer was prepared by reacting for 1 hour at 100°C.

[0021] (2) The above prepared water-based prepolymer, 5 parts of modified attapulgite, 1 part of tributyl phosphate, 1 part of sodium lauryl sulfate, phenyl bis(2,4,6-trimethyl Benzoyl) phosphorus oxide water dispersion and solvent-type 1-hydroxycyclohexyl phenyl ketone 0.5 part: 0.5 part are mixed and added as a photoinitiator, stirred at 35 degrees to allow it to react for 1 hour, and then add dipropylene glycol methyl ether 1 1 ...

Embodiment 2

[0024] (1) Preparation of water-based prepolymer: Add 15 parts of hyperbranched water-based polyurethane acrylic resin and 15 parts of 4-toluene isocyanate into a three-necked bottle with a stirring device, and add 50 ml of high boiling point solvent hexamethylphosphorous triamide , feed inert gas or nitrogen, stir and react for 1 hour at 65 degrees Celsius, then add 7 parts of piperidine-1,4-dihydroxypropanesulfonic acid and 7 parts of 2,3-dihydroxypropyl methacrylate at 52 The water-based prepolymer was prepared by reacting for 1 hour at 100°C.

[0025] (2) The above prepared water-based prepolymer, 7 parts of modified attapulgite, 2 parts of defoamer Deqian 3100, 2 parts of sodium lauryl sulfate, phenyl bis(2,4,6-trimethyl Benzoyl) phosphorus oxide aqueous dispersion and solvent-type 1-hydroxycyclohexyl phenyl ketone 1 part: 1 part are mixed and added as a photoinitiator, stirred at 35 degrees and allowed to react for 1 hour, and then added 2, 2, 4 - 2 parts of trimethyl-1...

Embodiment 3

[0028] (1) Preparation of water-based prepolymer: Add 20 parts of hyperbranched water-based polyurethane acrylic resin and 20 parts of 4-toluene isocyanate into a three-necked bottle with a stirring device, and add 50 ml of high boiling point solvent hexamethylphosphonotriamide , feed inert gas or nitrogen, stir and react for 1 hour at 65 degrees Celsius, then add 10 parts of piperidine-1,4-dihydroxypropanesulfonic acid and 10 parts of 2,3-dihydroxypropyl methacrylate at 52 The water-based prepolymer was prepared by reacting for 1 hour at 100°C.

[0029] (2) The water-based prepolymer prepared above, 10 parts of modified attapulgite, 3 parts of defoamer defoamer BYK088, 3 parts of alkyl diphenyl ether disulfonate, phenyl bis(2,4 , 6-trimethylbenzoyl) phosphorus oxide aqueous dispersion and solvent-type 1-hydroxycyclohexyl phenyl ketone 1.5 parts: 1.5 parts are mixed and added as a photoinitiator, stirred at 35 degrees to allow it to react for 1 hour, and then Add 3 parts of 3...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap