Rice mill provided with antibacterial rice sieve

A rice mill and antibacterial rice technology, applied in the field of rice mills, can solve the problems of easy growth of mold in internal functional parts, complicated work process, time-consuming and laborious, etc., achieve efficient and convenient screening treatment, prevent the growth of mold, and improve antibacterial properties. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

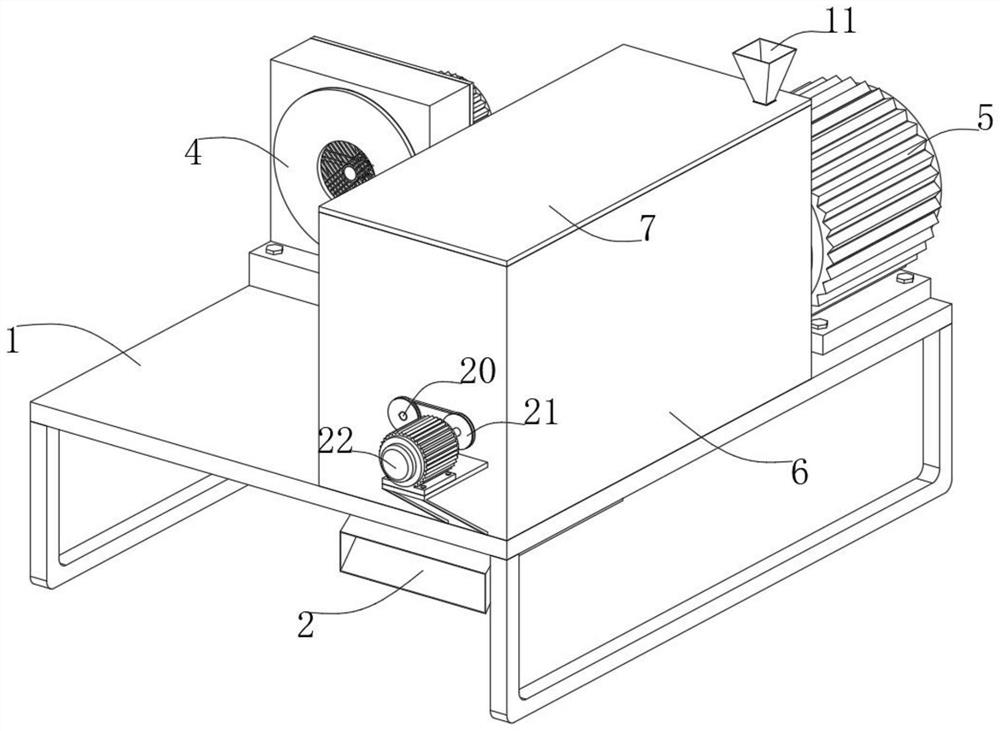

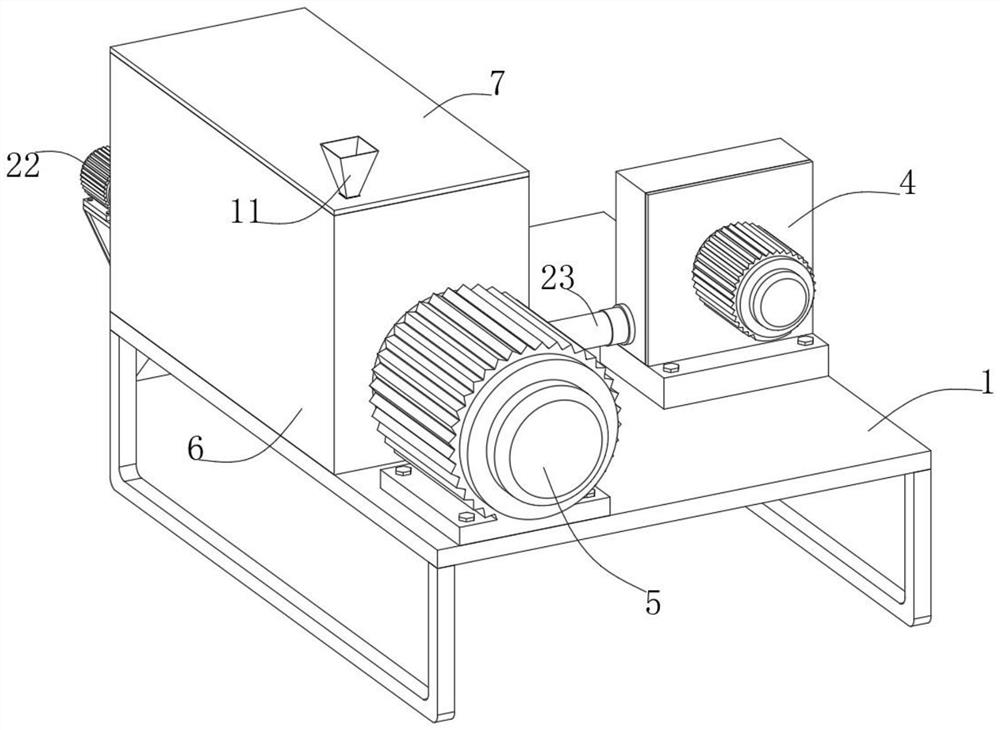

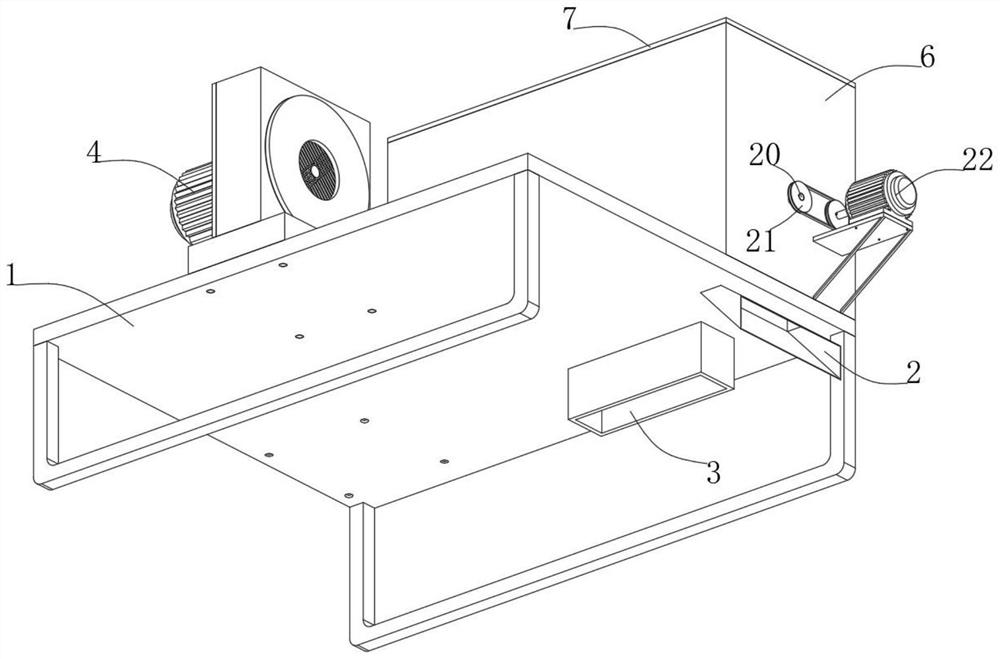

[0029] Embodiment one, with reference to Figure 1-8: A rice milling machine with an antibacterial rice sieve, including a base 1, a protective cover 7 and a limit block 18, the establishment of the base 1 provides the basis for the installation of other functional parts of the equipment, and at the same time enables the equipment to be placed firmly on the specified The place of use is to realize the efficient due function. The establishment of the protective cover 7 is to ensure that the internal functional parts of the equipment can normally realize the due function without being affected by the external environment. The establishment of the limit block 18 is effective in conjunction with the rotating frame 17 The rice sieve 19 is installed and fixed so that the equipment can efficiently sieve white rice. A motor 5 is arranged near a corner on the top of the base 1. The model of the motor 7 is YL, and the motor 5 is set up to effectively drive the rice milling. The machine ...

Embodiment 2

[0030] Embodiment two, refer to Figure 8-11 : the outer surface of the grinding tube 9 is provided with a connection port near the edge of one end, the connection port is set up to facilitate the installation of the feed pipe 10, and the inside of the connection port is welded with the feed pipe 10, the feed pipe 10 is set up for It can effectively transport the appropriate amount of rice inside the material injection frame 11 to the grinding tube 9, one end of the material guide tube 10 extends to the inside of the material injection port, and the inside of the material guide tube 10 is slidably embedded with a material injection frame 11. The establishment of the material injection frame 11 is In order to facilitate the effective input of paddy, so that the equipment can efficiently carry out the realization of due functions, the outer surface of one side of the air guide support block 8 is provided with an air guide pipe mouth 28 near the edge of one side. The establishment...

Embodiment 3

[0031] Embodiment three, refer to Figure 1-8 : the inner bottom surface of the screening chamber 6 is located below the first collecting port and is provided with a second collecting port. The second collecting port is set up to facilitate the collection of separated white rice. The front surface of the screening chamber 6 is welded near a corner. The support platform, the establishment of the support platform is to facilitate the installation of the small motor 22, and the top of the support platform is provided with a small motor 22. The rotating frame 17 is effectively driven to rotate, and the center of the outer surface of the small motor 22 slides through a second rotating shaft. The belt pulley 2 is sleeved, and the outer surface of the two pulleys 21 is covered with a belt. The belt is set up to cooperate with the pulley 21 so that the small motor 22 can effectively drive the rotating frame 17 to rotate. The bottom of the base 1 is located below the second collection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com