Dimension precision detection method and device, electronic equipment and storage medium

A technology of dimensional accuracy and detection method, which is applied in the direction of measuring devices, optical devices, image data processing, etc., can solve problems affecting production efficiency, achieve the effect of improving detection efficiency, avoiding the impact of detection efficiency and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

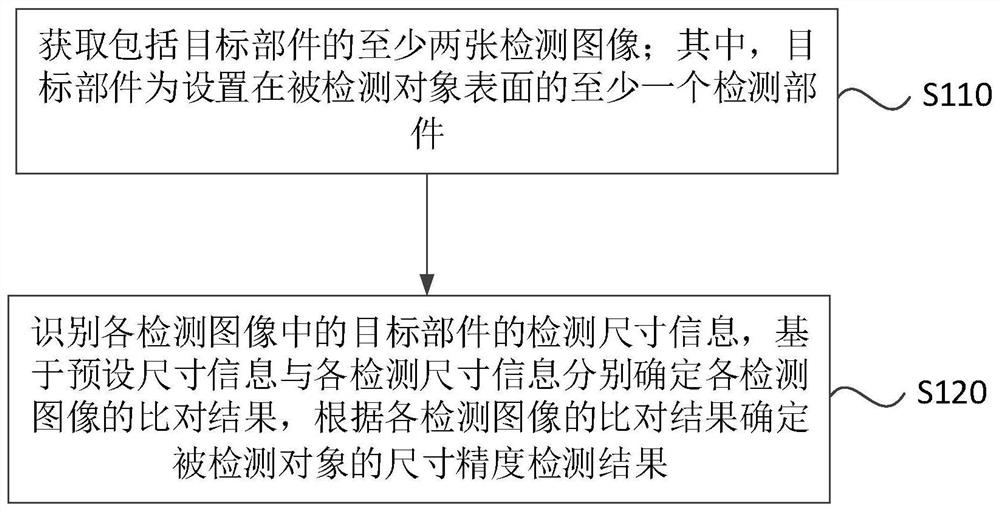

[0045] figure 1 It is a flow chart of a method for detecting dimensional accuracy provided by Embodiment 1 of the present invention. This embodiment is applicable to performance testing in software testing. The method can be executed by a measuring device for dimensional accuracy, and the device can be realized by means of software and / or hardware.

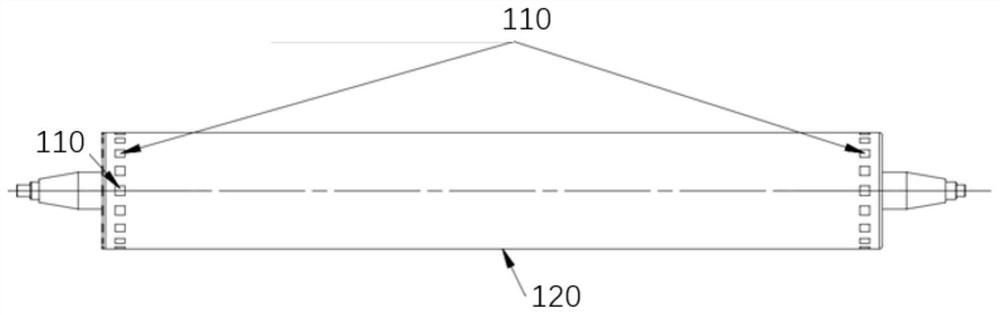

[0046] Before introducing the technical solutions of the embodiments of the present invention, the application scenarios of the embodiments of the present invention are first introduced as examples. Of course, the following application scenarios are only optional application scenarios, and the technical solutions of this embodiment can also be applied to other applications. Scenarios are not limited in this embodiment. Specifically, the application scenarios of this embodiment include: in the current lithium battery coating production process, it is necessary to test the dimensional accuracy of the production equipment before pro...

Embodiment 2

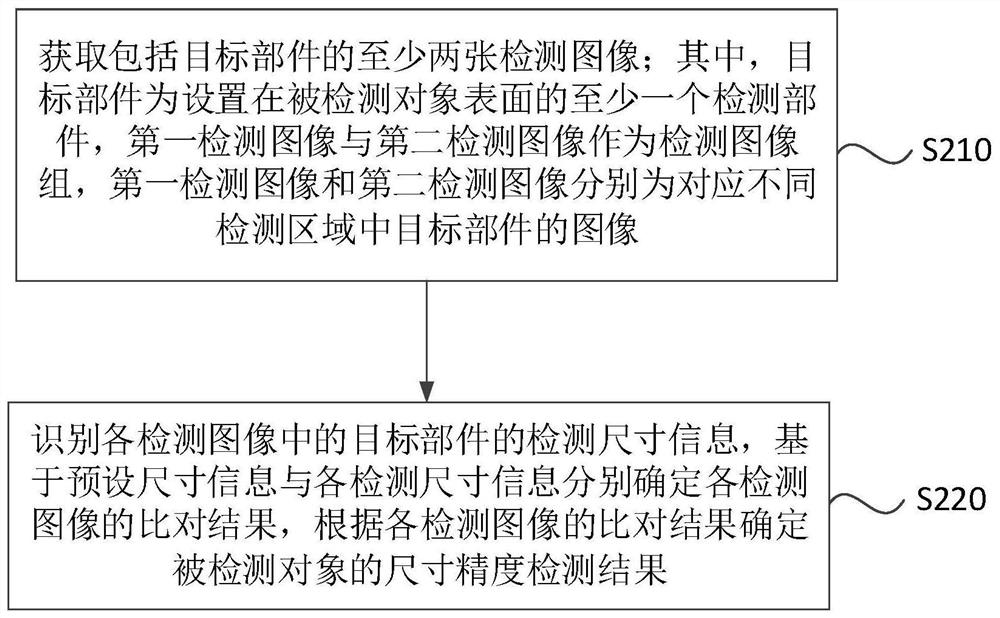

[0062] image 3 It is a flow chart of a dimensional accuracy detection method provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, in this embodiment, in the step "obtain at least two detection images including target components; wherein, the target components are On the basis of at least one inspection component set on the surface of the object to be inspected, "the first inspection image and the second inspection image are used as the inspection image group, and the first inspection image and the second inspection image respectively correspond to the target parts in different inspection areas. The image of ", where the explanations of terms that are the same as or corresponding to the above-mentioned embodiments will not be repeated here.

[0063] see image 3 , the detection method of the dimensional accuracy provided in this embodiment includes:

[0064] S210. Acquire at least two detection images including the target compon...

Embodiment 3

[0075] Figure 4 It is a schematic structural diagram of the detection device for dimensional accuracy provided by Embodiment 3 of the present invention, and this embodiment is applicable to performance testing in software testing. The specific structure of the detection device of the dimensional accuracy includes: a detection image acquisition module 310 and a detection result determination module 320; wherein,

[0076] A detection image acquisition module 310, configured to obtain at least two detection images including a target component; wherein, the target component is at least one detection component disposed on the surface of the detected object;

[0077] The detection result determination module 320 is used to identify the detected size information of the target component in each of the detected images, and determine the comparison result of each of the detected images based on the preset size information and each of the detected size information, and according to each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com