Simple sample vacuum device for intense laser damage experiment

A vacuum device and strong laser technology, applied in measuring devices, material analysis through optical means, instruments, etc., to achieve high vacuum, low cost, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

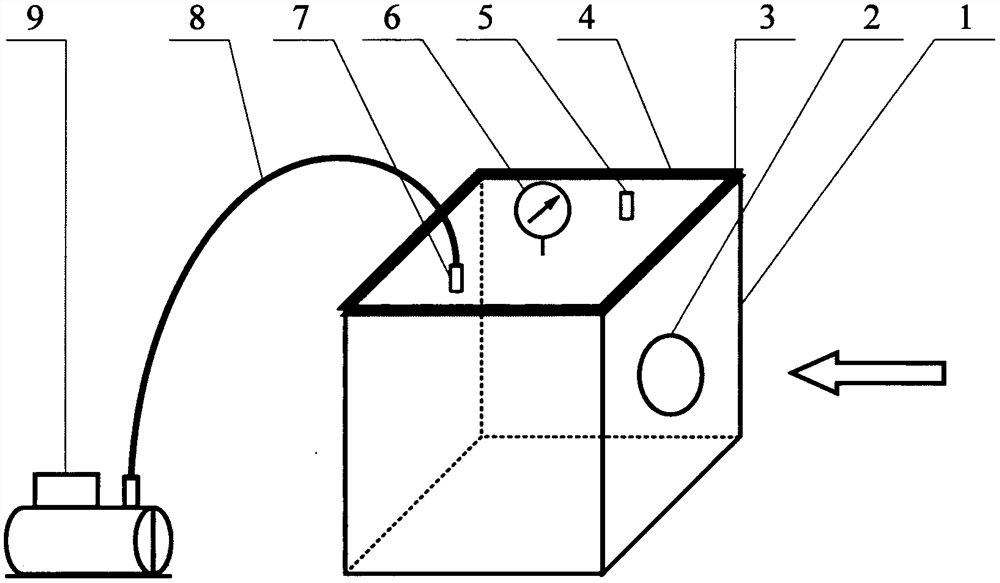

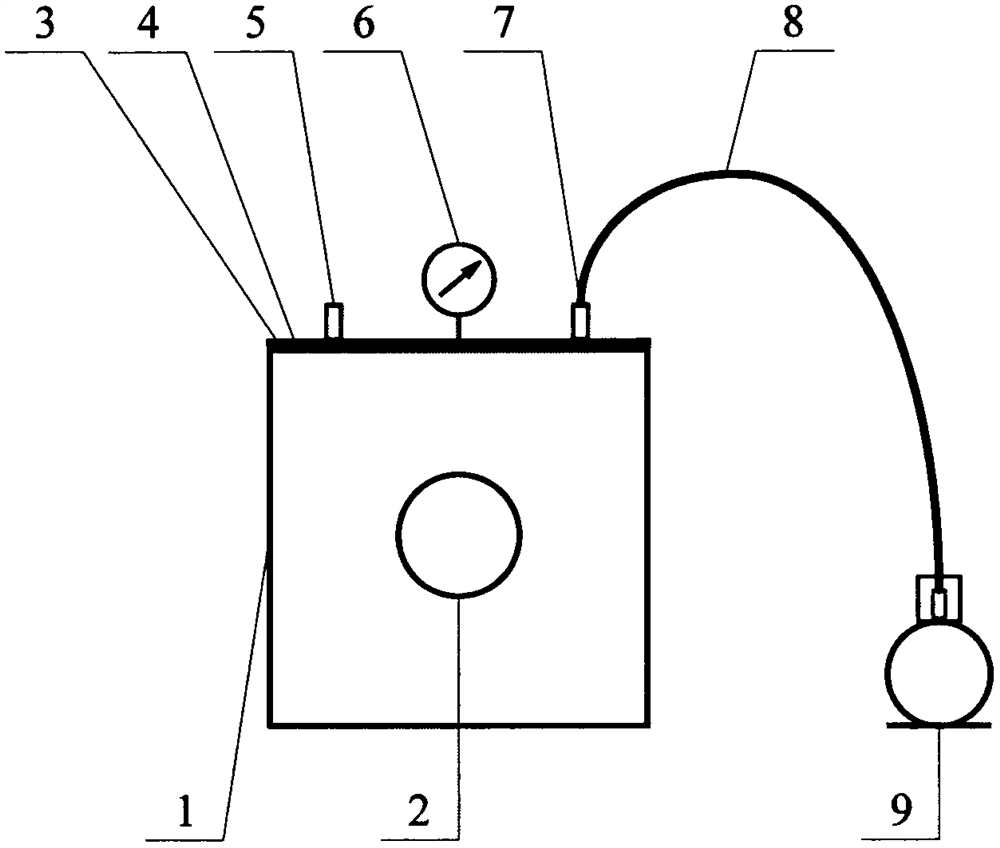

[0023] like figure 1 As shown, a simple sample vacuum device for strong laser damage experiments, including: lower housing-1, laser incident window-2, upper housing-3, rubber gasket-4, air return valve-5, air pressure Meter-6, exhaust valve-7, vacuum tube-8 and mechanical vacuum pump-9.

[0024] Among them: one side of the lower housing-1 is horizontally equipped with a laser incident window-2, the lower housing-1 and the upper housing-3 are fastened and connected by a buckle mechanism, and there is a rubber gasket-4 between the two housings to ensure the tightness , the sample to be damaged can be placed inside the vacuum box by opening the upper casing-3; the upper part of the upper casing-3 is installed with a return valve-5, a barometer-6 and an exhaust valve-7, and an exhaust valve-7 It is connected to the mechanical vacuum pump-9 through the matching vacuum tube-8; the strong laser is incident on the sample to be damaged inside the box through the laser incident window-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com