Polygonal heating furnace and using method thereof

A polygonal heating furnace technology, applied in the field of heating furnaces, can solve the problems of large floor space, lax furnace door closing, heavy workload, etc., and achieve the effects of convenient installation and disassembly, convenient installation and disassembly, and fast heating speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

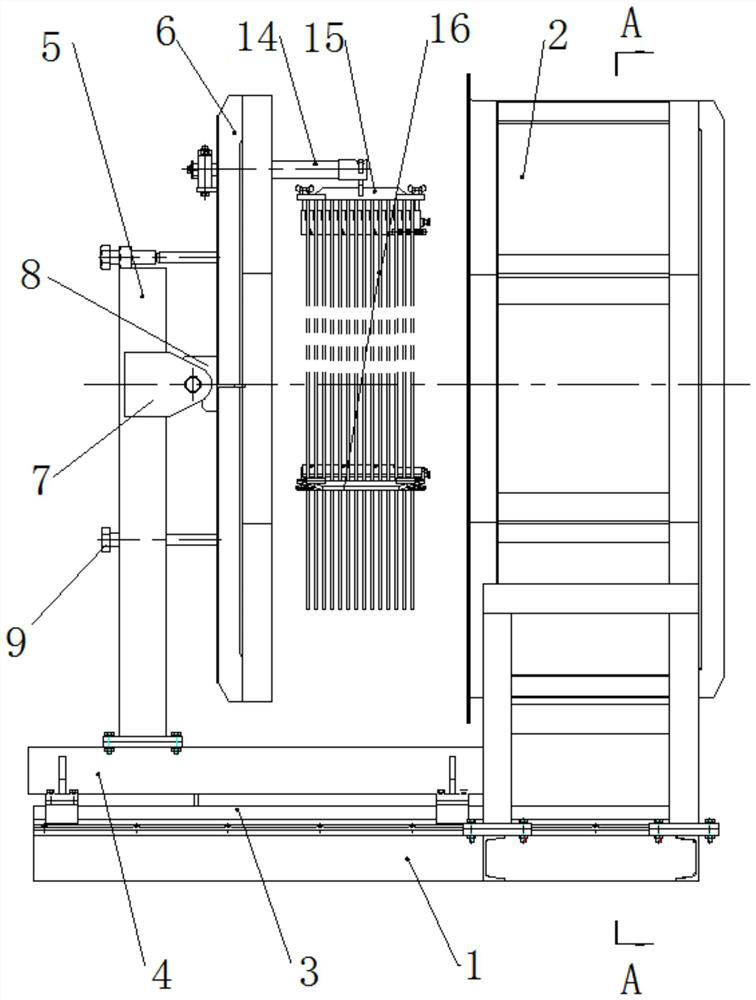

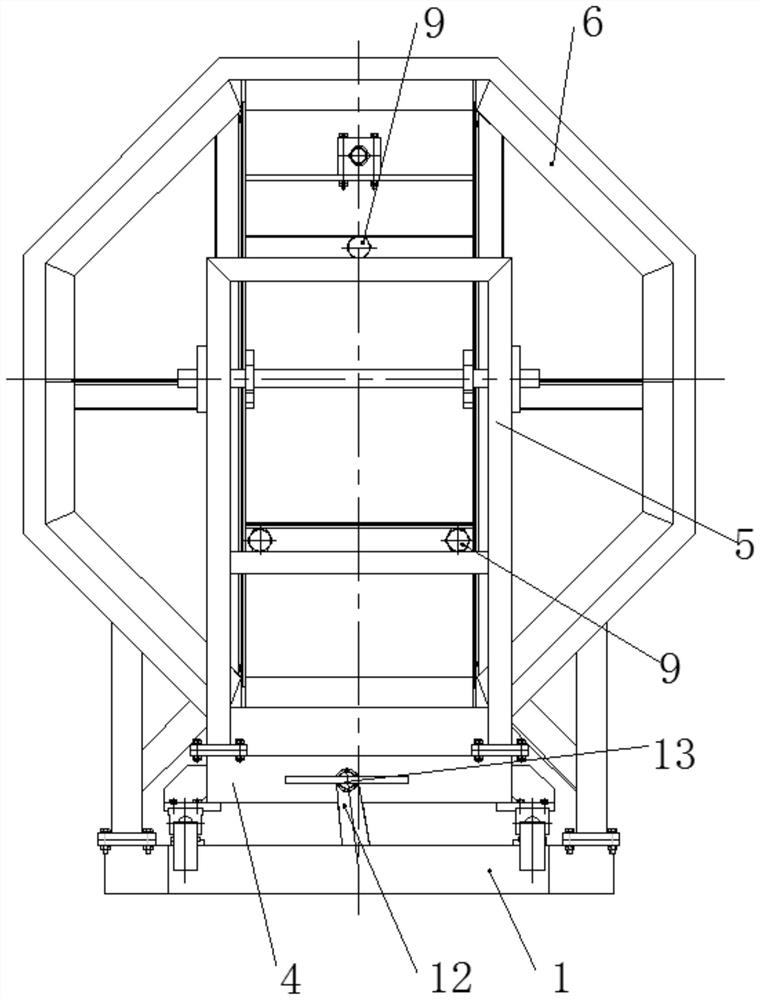

[0035] Such as Figure 1-3 As shown, a polygonal heating furnace includes a furnace base 1, two linear guide rails 3 are arranged on the upper side of the furnace base 1, and a polygonal furnace 2 is arranged on one end of the upper side of the linear guide rail 3, and the linear guide rail 3 is arranged along the axis of the furnace 2 The other end of the upper side of the linear guide rail 3 is provided with a sliding furnace door seat 4, and both sides of the lower end of the furnace door seat 4 are fixed with sliding seats. The sliding seat moves along the linear guide rail 3, and the lower end of the furnace 2 is fixed with a bracket. The bracket is fixedly connected with the furnace base 1 , and the lower end of the furnace 2 and the upper side of the linear guide rail 3 are spaced apart to provide space for the movement of the furnace door seat 4 .

[0036] The upper end of the furnace door seat 4 is fixed with a furnace door bracket 5, which is connected to a polygonal...

Embodiment 2

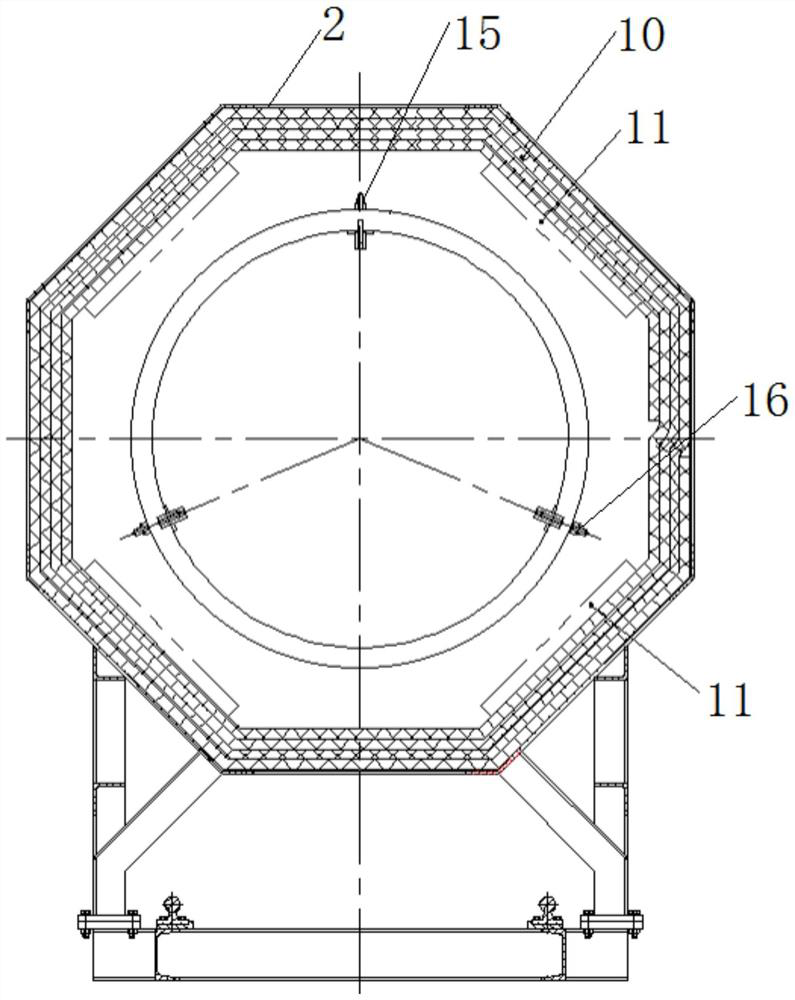

[0041] This embodiment is basically the same as Embodiment 1, the difference is that, as figure 1 and 4 As shown, the workpiece mounting mechanism includes a mounting rod 14 and a fixed-distance gripper, and the fixed-distance gripper includes a first-type gripper 15 and several second-type grippers 16, and the mounting rod 14 is fixed on the furnace door 6 Above, the first-type clamper 15 is suspended on the mounting rod 14, and the first-type clamper 15 and several second-type clampers 16 are evenly distributed along the circumferential direction of the sheet-shaped annular workpiece.

[0042] Such as Figure 5 and 6 As shown, the first-type clamper 15 and the second-type clamper 16 both include two comb-shaped positioning plates 15-1 arranged at intervals, and a comb-shaped clamping plate is slidingly arranged between the two comb-shaped positioning plates 15-1 15-2, the comb-shaped positioning plate 15-1 includes a first strip-shaped body 15-3, the upper end of the firs...

Embodiment 3

[0050] A method for using a polygonal heating furnace, comprising the following steps:

[0051] (1) Install the workpiece on the workpiece mounting mechanism, move the furnace door 6 to the furnace 2 along the linear guide rail 3, and at the same time, the furnace door 6 drives the workpiece into the furnace 2;

[0052] (2) Then turn 3 adjusting bolts to make the furnace door 6 fully contact with the sealing surface of the furnace 2, and complete the closing of the furnace door 6;

[0053] (3) After the heating of the workpiece is completed, the furnace door 6 is reversely moved along the linear guide rail 3, and then the workpiece is removed from the workpiece mounting mechanism.

[0054] Further, in step (1), the workpiece is mounted on the workpiece mounting mechanism, and the specific steps are as follows:

[0055] 1) First install the fixed-distance holder: pass the comb-shaped positioning plate 15-1 through the shaft holes of multiple sheet-shaped ring workpieces, and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com