A waste gas discharge pipe for petroleum smelting

A technology for exhaust gas emission and petroleum smelting, which is applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc. It can solve the problems of damaged pipeline joints, loose pipeline joints, and difficult repairs, so as to reduce damage and reduce safety. hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

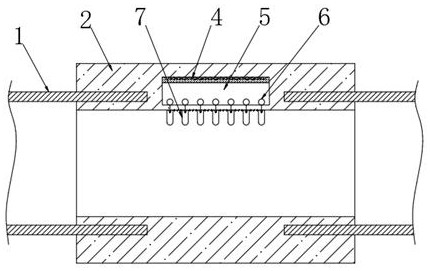

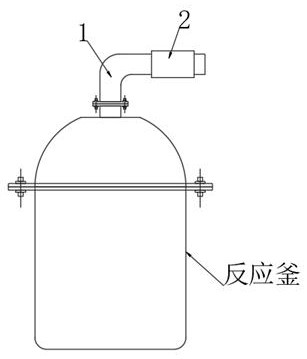

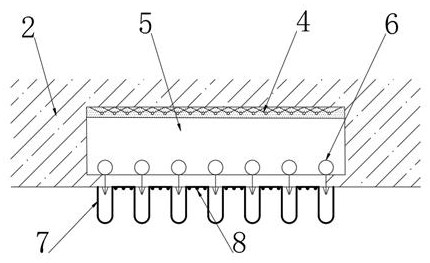

[0037] see Figure 1-3 , a waste gas discharge pipeline for petroleum smelting, including an exhaust pipe 1 installed on the exhaust port of a reaction kettle for petroleum production, a color change tube 2 is connected to the middle of the exhaust pipe 1, and an early warning color change cavity is dug inside the upper end of the color change tube 2 5. The top of the early warning discoloration cavity 5 is fixedly connected with the color change layer 4, and the inner bottom of the early warning discoloration cavity 5 is provided with a plurality of evenly distributed transfer chromospheres 6, and the color change tube 2 is dug with a plurality of transfer chromospheres respectively connected with multiple transfer chromospheres 6 corresponds to the through hole, the end of the transfer chromosphere 6 moves through the through hole and is fixedly connected with the inner wall of the color change tube 2, and the inner wall of the color change tube 2 is fixedly connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com