Waterproof spraying liquid for down jacket and preparation method of waterproof spraying liquid

A technology for down jackets and spraying liquid, applied in the field of down jackets, can solve the problems such as poor air permeability of down jackets, achieve good waterproof protection effect, avoid insufficient filling, outstanding surface activity and lubricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

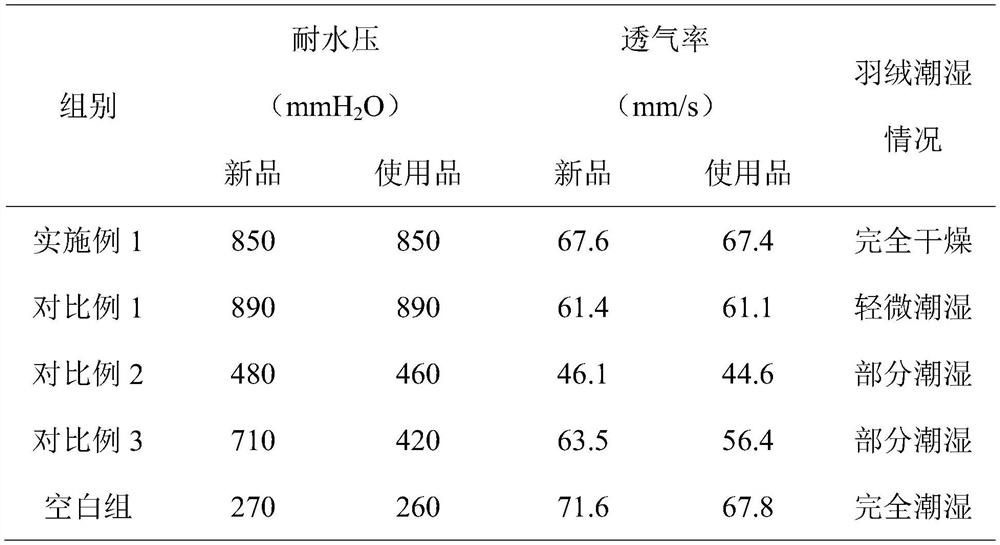

Examples

Embodiment 1

[0022] A waterproof spraying solution for down jackets, comprising A component and B component, and the A component is sprayed on the outer surface of the B component during spraying. Wherein, the A component includes a binder, a porous framework material and a water-absorbing swelling agent filled in the pores of the porous framework material, the binder is vinyltrimethoxysilane, and the amount added is the porous framework material and the water-absorbing swelling agent 5% of the total weight, the porous framework material is macroporous titanium dioxide, and the pore median diameter is 80nm, the volume filling rate of the water-absorbing swelling agent is 5%, and the water-absorbing swelling agent is composed of modified bentonite and alginic acid, modified The median diameter of the bentonite is 5nm, and the weight ratio of the modified bentonite to alginic acid is 3:1; the B component includes a porous separator, and the porous separator is a porous polyurethane resin.

...

Embodiment 2

[0028] A waterproof spraying solution for down jackets, comprising A component and B component, and the A component is sprayed on the outer surface of the B component during spraying. Among them, the A component includes a binder, a porous framework material and a water-absorbing swelling agent filled in the pores of the porous framework material. 10% of the total weight of the agent, the porous framework material is macroporous silica, and the pore median diameter is 250nm, the volume filling rate of the water-absorbing swelling agent is 12%, and the water-absorbing swelling agent is composed of modified bentonite and alginic acid , the median diameter of the modified bentonite is 30nm, and the weight ratio of the modified bentonite to alginic acid is 7:1; the B component includes a porous separator, and the porous separator is a porous polyurethane resin.

[0029] The preparation method of this waterproof spray liquid, the step comprises:

[0030] (1) Preparation of compone...

Embodiment 3

[0034] A waterproof spraying solution for down jackets, comprising A component and B component, and the A component is sprayed on the outer surface of the B component during spraying. Wherein, the A component includes a binder, a porous framework material and a water-absorbing swelling agent filled in the pores of the porous framework material, the binder is vinyltrimethoxysilane, and the amount added is the porous framework material and the water-absorbing swelling agent 20% of the total weight, the porous framework material is macroporous silica, and the pore median diameter is 500nm, the volume filling rate of the water-absorbing swelling agent is 20%, and the water-absorbing swelling agent is composed of modified bentonite and alginic acid, The median diameter of the modified bentonite is 50nm, and the weight ratio of the modified bentonite to alginic acid is 10:1; the B component includes a porous separator, and the porous separator is a porous polyurethane resin.

[0035...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com