Printable anti-scratch anti-static protective film and preparation method thereof

An antistatic and anti-scratch technology, applied in the field of materials, can solve the problems of non-scratch-resistant PU protective film surface, no printing, anti-scratch, local anti-static instability, etc., to reduce the coating of anti-static film steps, excellent transferability, and the effect of preventing silicon transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

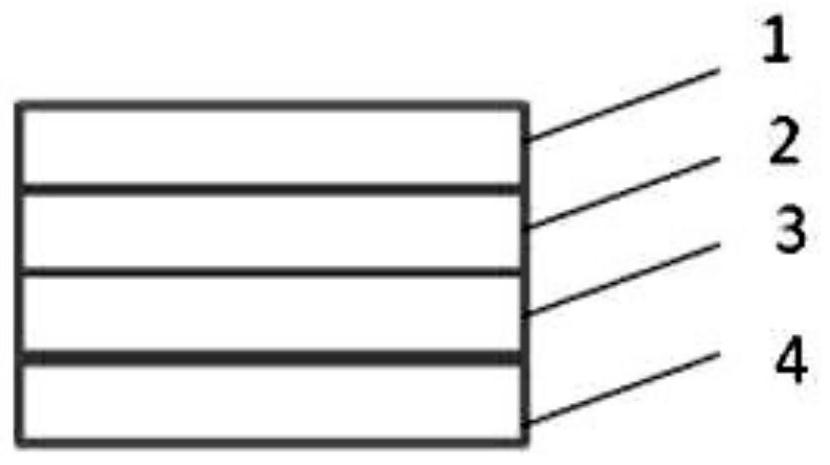

[0021] Such as figure 1 As shown, the present invention provides a printable anti-scratch antistatic protective film, which includes a printable anti-scratch coating 1, an optical PET substrate layer 2, a modified antistatic layer 3 and a non-silicon ionizer from top to bottom. Type film layer 4, the material of the printable anti-scratch coating 1 is polyurethane, and the modified antistatic layer 3 is an antistatic polyurethane adhesive layer. The thickness of the printable anti-scratch coating 1 is 2 μm, the thickness of the optical PET substrate layer 2 is 50 μm, the thickness of the modified antistatic layer 3 is 15 μm, and the thickness of the non-silicon release film layer 4 is 50 μm.

[0022] The invention provides a method for preparing a printable anti-scratch antistatic protective film, comprising:

[0023] Preparation of antistatic polyurethane glue: add polythiophene to polyurethane glue, the mass ratio of polythiophene to polyurethane glue is 3:97.

[0024] On ...

Embodiment 2

[0026] Such as figure 1 As shown, the present invention provides a printable anti-scratch antistatic protective film, which includes a printable anti-scratch coating 1, an optical PET substrate layer 2, a modified antistatic layer 3 and a non-silicon ionizer from top to bottom. Type film layer 4, the material of the printable anti-scratch coating 1 is polyurethane, and the modified antistatic layer 3 is an antistatic polyurethane adhesive layer. The thickness of the printable anti-scratch coating 1 is 4 μm, the thickness of the optical PET substrate 2 layer is 100 μm, the thickness of the modified antistatic layer 3 is 10 μm, and the thickness of the non-silicon release film layer 4 is 25 μm.

[0027] The invention provides a method for preparing a printable anti-scratch antistatic protective film, comprising:

[0028] Preparation of antistatic polyurethane glue: Add polythiophene to polyurethane glue, and the mass ratio of polythiophene to polyurethane glue is 10:90.

[002...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com