Automobile engine valve locking plate grinding equipment

A technology of automobile engine and valve lock plate, which is applied in grinding/polishing equipment, grinding feed motion, grinding drive device, etc., can solve the problems of difficult operation, low processing efficiency, time-consuming and laborious, etc., and achieve high-efficiency automation Processing process, the effect of inclination adjustment, and reliable mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

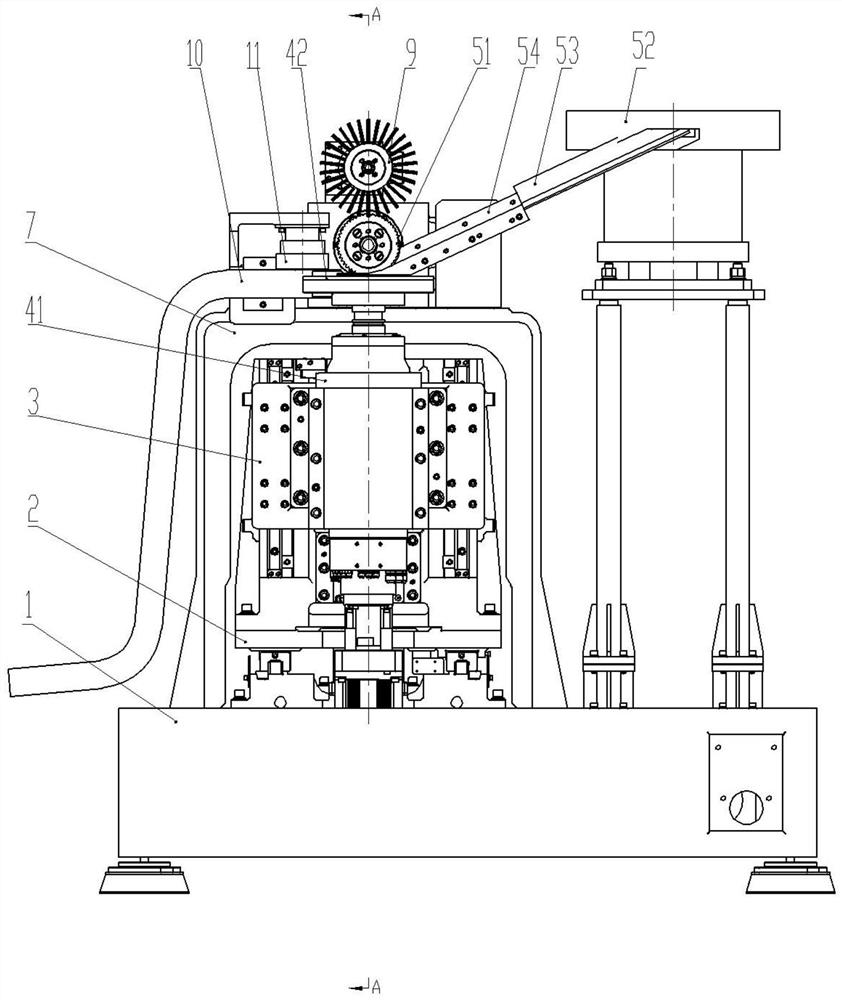

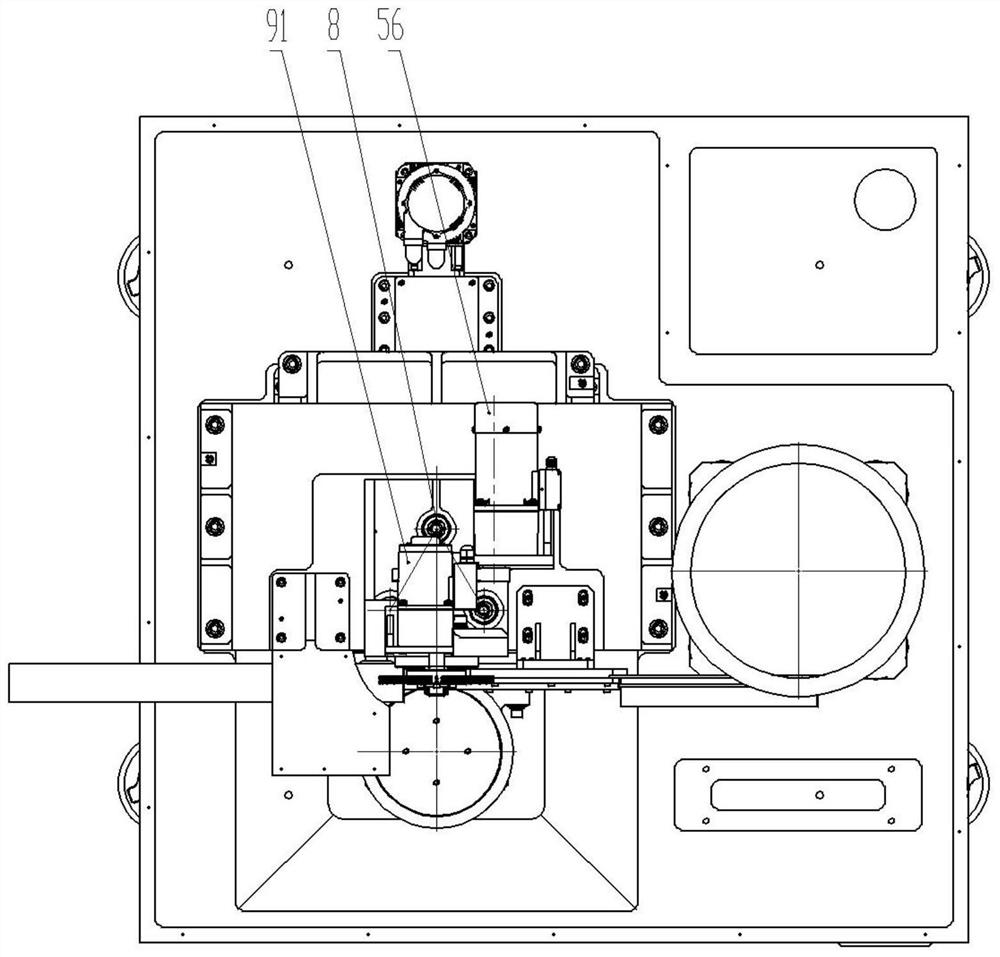

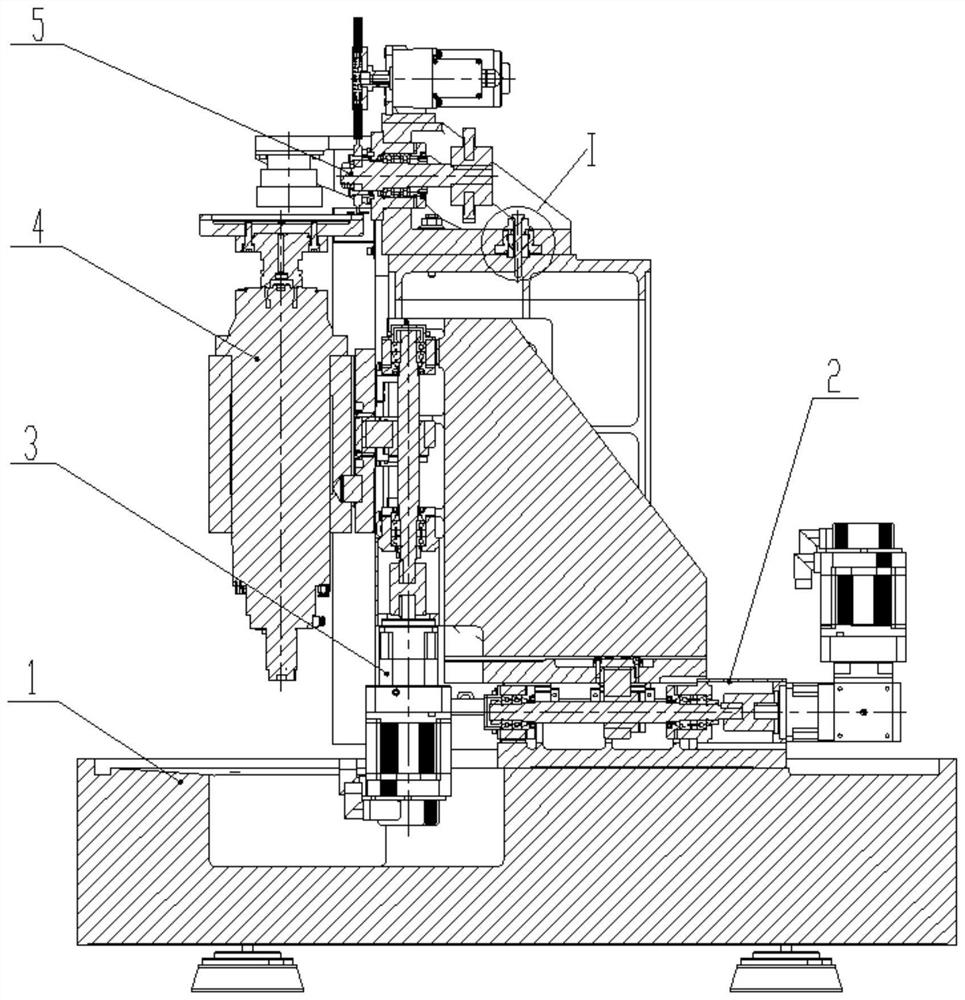

[0032] Such as Figure 1-3 As shown, this embodiment includes a bed 1, a horizontal movement mechanism 2, a vertical movement mechanism 3 and a grinding mechanism 4 provided on the bed 1, and the grinding mechanism 4 includes an electric spindle 41 and a CBN grinding wheel 42. A feeding mechanism 5 is provided above the grinding mechanism 4, and the feeding mechanism 5 clamps the workpiece with the feeding profiling wheel 51 as a fixture and transports it to the emery wheel 52 for grinding. The feeding mechanism 5 is provided with an inclination adjustment mechanism 6. The power source of the feeding mechanism 5 is the first speed-regulating motor 56, which can control the speed of the profiling feeding wheel 51 through the deceleration of the precision gear pair 57.

[0033] Such as Figure 7 As shown, the body of the feeding profi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com