Calcium-containing gangue combined inhibitor for scheelite flotation as well as preparation method and application method thereof

A technology combining inhibitors and scheelite, which is applied in flotation, process efficiency improvement, solid separation, etc., can solve serious environmental pollution and other problems, achieve the effects of less dosage, improved flotation effect, and enhanced inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment 1

[0023] A combined calcium-containing gangue depressant for scheelite flotation. The components are sodium lignosulfonate, humic acid and carboxylated chitosan, and the contents are respectively 40%, 50% and 10%.

[0024] A preparation method of the calcium-containing gangue combined inhibitor for scheelite flotation, comprising: 40% sodium lignosulfonate, 50% humic acid, 10% carboxylated chitosan %, mixed to prepare the calcium-containing gangue combined inhibitor DWC for scheelite flotation, then heated to 80°C, added water until the mass concentration of the inhibitor DWC was 20%, and stirred at a high speed of 1000r / min After 10 minutes, an aqueous solution of the inhibitor DWC was prepared, which was further diluted to a 2% solution for later use.

[0025] A method for flotation scheelite using the above combined inhibitor, comprising:

[0026] (1) Grind the scheelite through a ball mill to -74 microns and account for 70%; the adopted scheelite contains tungsten (WO 3 ) ...

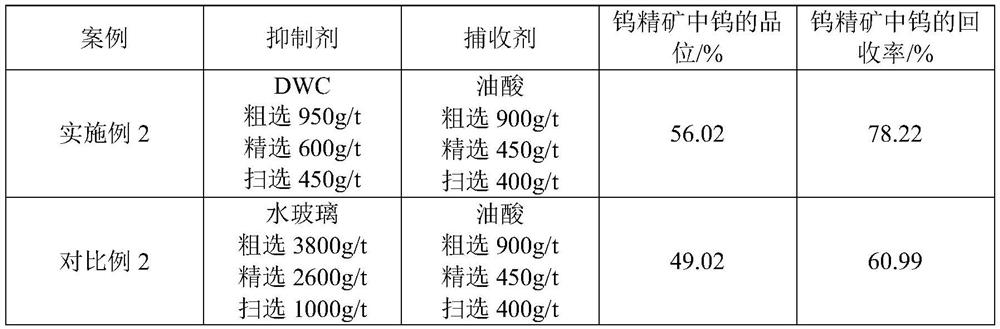

Embodiment 2

[0034] A combined calcium-containing gangue depressant for scheelite flotation. The components are sodium lignosulfonate, sodium humate and carboxylated chitosan, and the contents are respectively 40%, 55% and 5%. A preparation method of the calcium-containing gangue combined inhibitor for scheelite flotation, comprising: 40% sodium lignosulfonate, 55% sodium humate, carboxylated chitosan 5%, mixed to prepare the calcium-containing gangue combined inhibitor DWC for scheelite flotation, then heated to 80°C, added water until the mass concentration of the inhibitor DWC was 30%, at a high speed of 1500r / min Stir for 15 minutes to prepare an aqueous solution of the inhibitor DWC, which is further diluted to a 2% solution for later use.

[0035] A method for flotation scheelite using the above combined inhibitor, comprising:

[0036] (1) Grind the scheelite through a ball mill to -74 microns and account for 75%; the adopted scheelite contains tungsten (WO 3 ) is about 0.54%, CaO ...

Embodiment 3

[0044] A combined calcium-containing gangue depressant for scheelite flotation. The components are sodium lignosulfonate, sodium humate, and carboxylated chitosan, and the contents are respectively 35%, 60%, and 5%.

[0045] A preparation method of the calcium-containing gangue combined inhibitor for scheelite flotation, comprising: 35% sodium lignosulfonate, 60% sodium humate, carboxylated chitosan 5%, mixed to prepare the calcium-containing gangue combined inhibitor DWC for scheelite flotation, then heated to 80°C, added water until the mass concentration of the inhibitor DWC was 25%, at a high speed of 1200r / min Stir for 10 min to prepare an aqueous solution of the inhibitor DWC, which is further diluted to a 2% solution for later use.

[0046] A method for flotation scheelite using the above combined inhibitor, comprising:

[0047] (1) Grind the scheelite through a ball mill to -74 microns and account for 75%; the adopted scheelite contains tungsten (WO 3 ) is about 0.36%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com