Efficient dashboard assembly safety air bag installation and detection mechanism

An airbag and detection mechanism technology, applied in the field of high-efficiency instrument panel assembly airbag installation detection mechanism, can solve the problems of increased failure rate of motor and rotating shaft, heavy weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

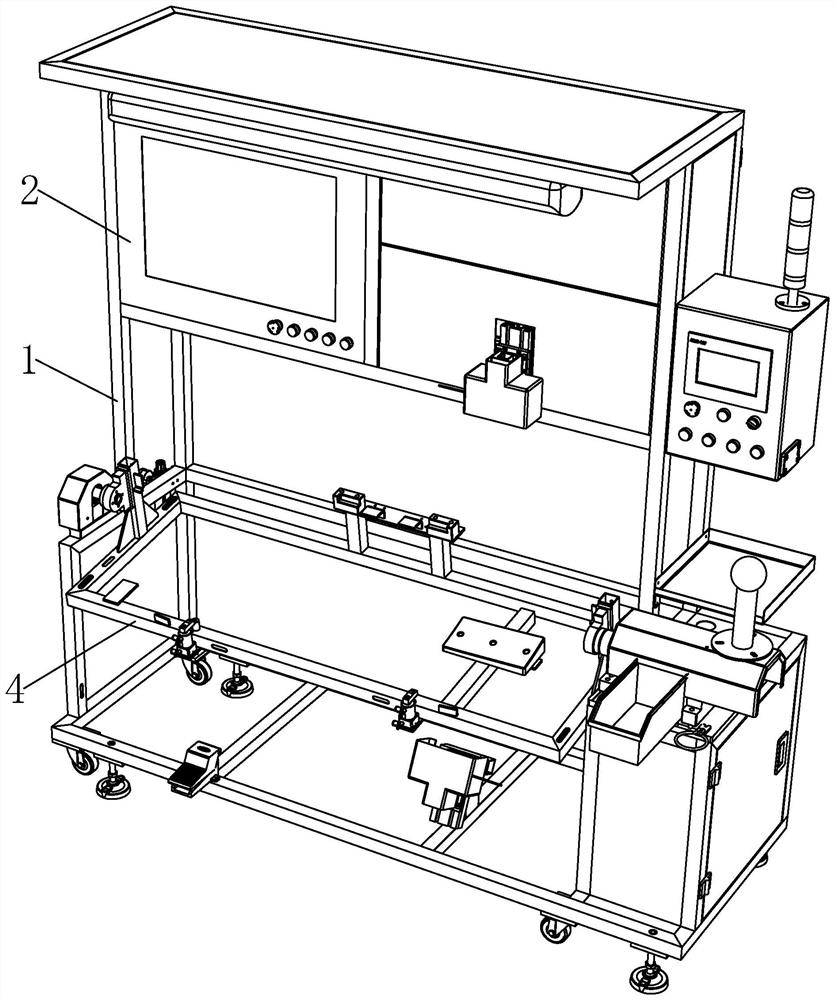

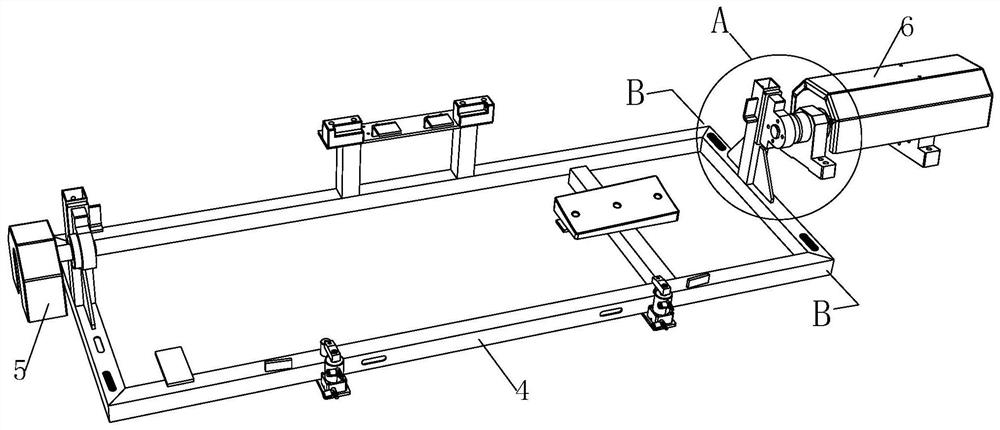

[0035] see image 3 , Figure 4 , Figure 5 as well as Figure 12 , a booster mechanism used for instrument panel assembly safety airbag installation detection, used to automatically boost the movement of the movable mechanism 4, including a bearing seat 5, a motor 6 and a rotating shaft 11 installed on the power output end of the motor 6, the rotating shaft 11 and the bearing housing 5 are rotatably connected with the moving mechanism 4 through a connecting mechanism, and also include a path recording mechanism for recording the moving path of the moving mechanism 4. The path recording mechanism includes a signal generating mechanism, a signal receiving and detecting mechanism, and a signal receiving and detecting mechanism. The single-chip processor 3 electrically connected to the mechanism; the booster mechanism body, which can accurately plan the boosting direction according to the moving path of the movable mechanism 4 .

[0036] Please refer to 3-5, the shaft 11 betwe...

Embodiment 2

[0043] Unlike Example 1, see Figure 9 with Figure 10 The signal generating mechanism includes a plurality of signal transmitting modules 19 fixedly arranged on the convex plate 12, and the signal receiving and detecting mechanism includes a signal receiving module 20 also fixedly arranged on the positioning seat 15; a plurality of signal transmitting modules 19 are equidistantly distributed and The signals sent out are different, and as the rotating shaft 11 drives the convex plate 12 to rotate, the signal receiving module 20 can be aligned with a plurality of signal transmitting modules 19 in sequence; the signal receiving module 20 converts the received different signals into different electric signals The signal is then transmitted to the single-chip processor 3.

[0044] In this embodiment, the signal transmitting module 19 and the signal receiving module 20 can be of various types, for example: an ultrasonic transmitting module and an ultrasonic receiving module, an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com