Ignition gun

A technology for ignition guns and conveying pipes, applied in the field of ignition guns, can solve the problems of difficult ignition, difficulty in reaching combustion-supporting air, accurate ratio of gas fuel, poor anti-interference ability of flames, etc., and achieve the effect of slender flames

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

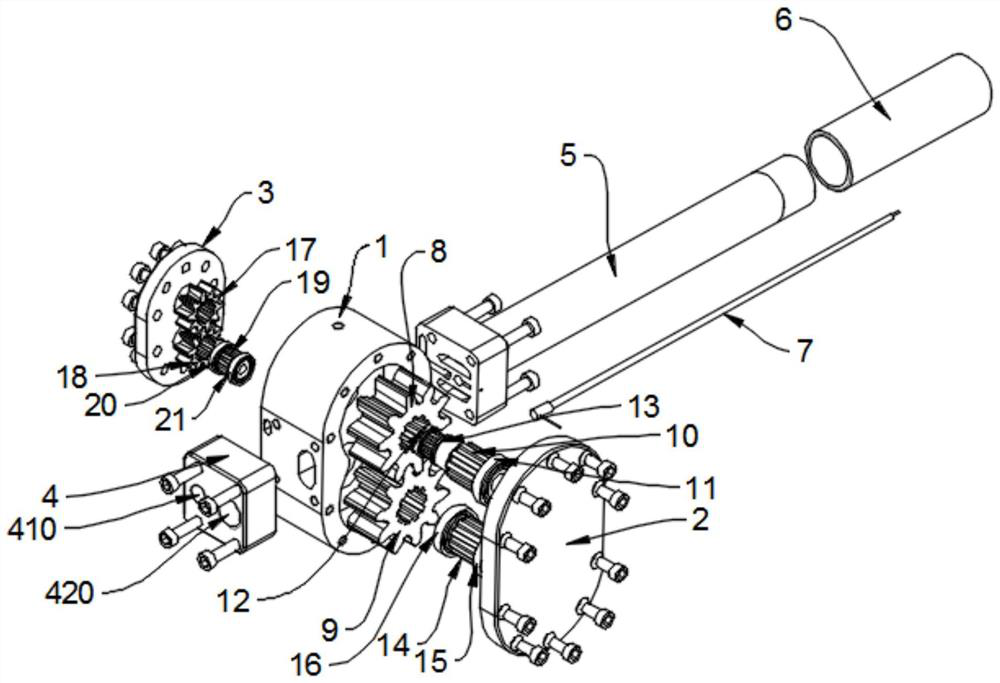

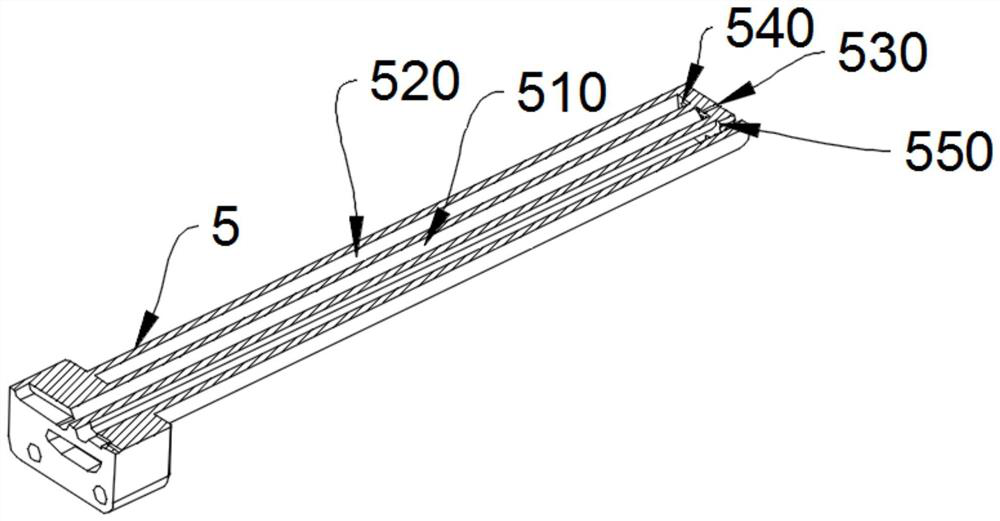

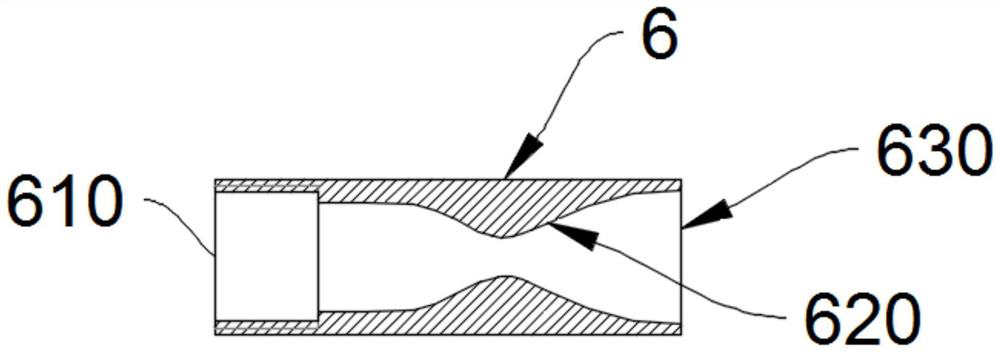

[0035] like figure 1 As shown, an ignition gun includes a delivery pipe 5 and a nozzle 6. One end of the delivery pipe 5 is provided with a proportioner, and the other end is detachably connected to the nozzle 6. The proportioner includes a transmission mechanism, an inlet end cover and a transmission mechanism for installing And the proportioner body of the inlet end cover, there is a partition in the middle of the cavity of the proportioner body 1, and the partition divides the cavity of the proportioner body 1 into two conveying cavities; the transmission mechanism includes a transmission mechanism 1 and a transmission mechanism 2 , the transmission mechanism 1 and the transmission mechanism 2 are respectively placed in the two conveying cavities of the proportioner body 1, and the cavity volume ratio of the two conveying cavities minus the volume occupied by the transmission mechanism is the air-combustion ratio. A through hole, the transmission shaft 2 (10) on the transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com