Compressor shell with efficient sound absorption structure

A compressor shell and high-efficiency technology, applied in the field of compressors, can solve problems such as poor protection of the compressor shell, inconvenient long-distance transportation for users, and impact on the user's working environment, so as to maintain completeness and facilitate transportation And the effect of using and avoiding collision damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

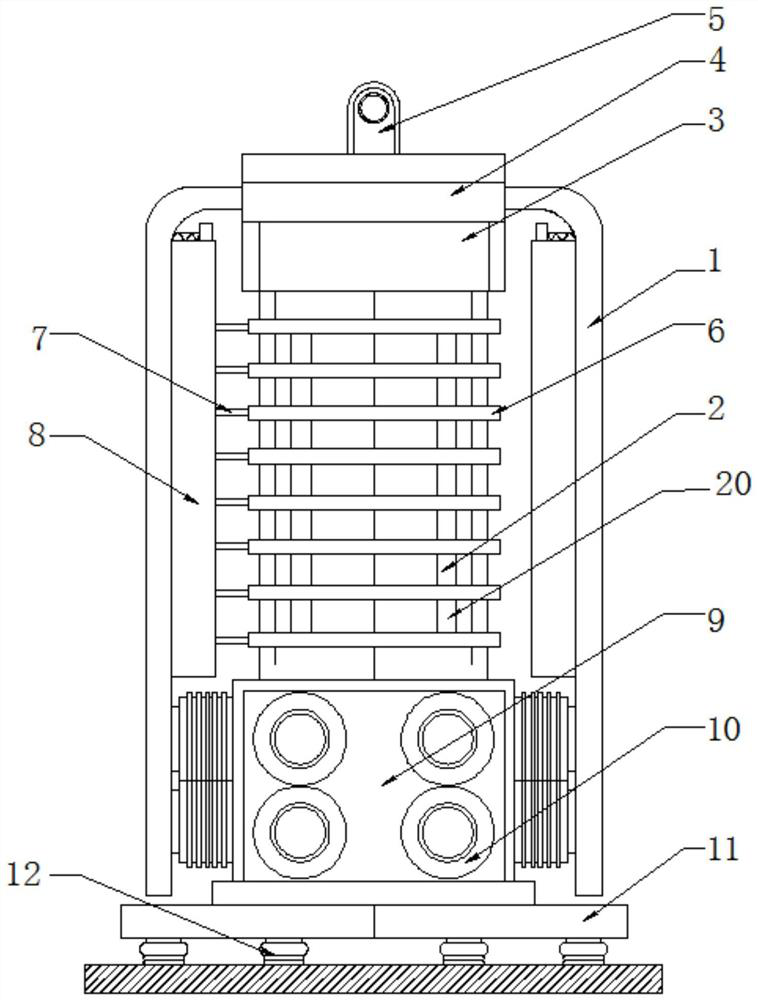

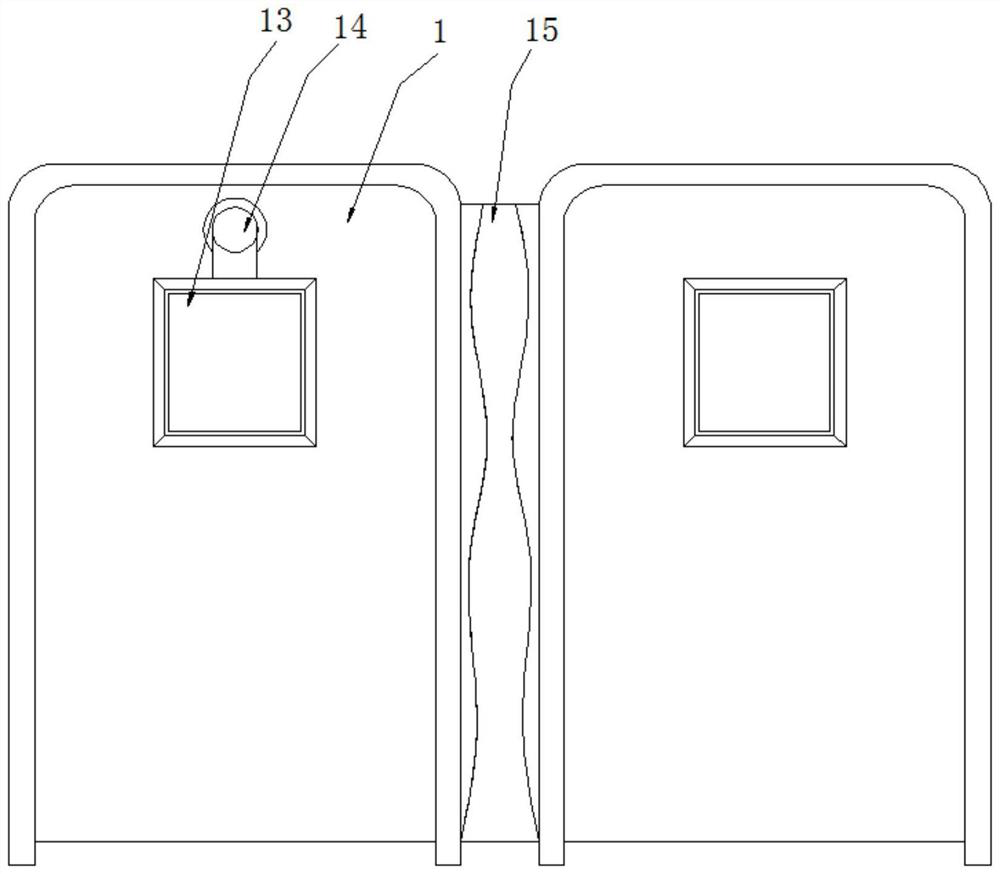

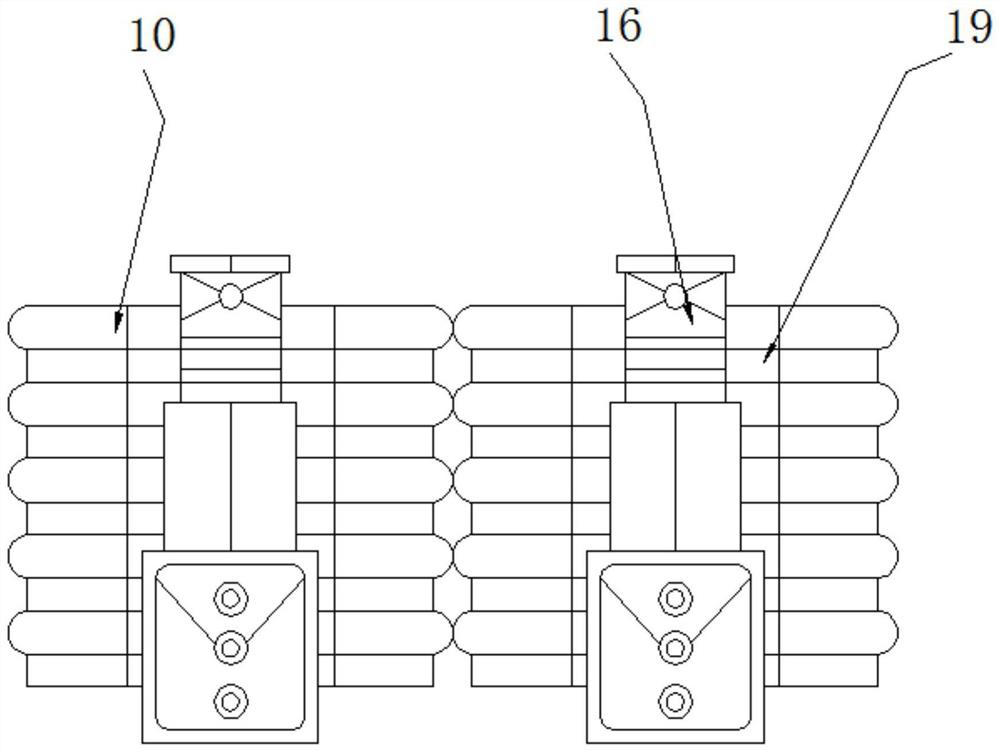

[0028] see Figure 1 to Figure 5 , the present invention provides a technical solution: a compressor shell with a high-efficiency sound-absorbing structure, including an outer shell 1, a main shell 2, a top cover 3, a ring groove 4, an engaging hook 5, an auxiliary plate 6, a push rod 7, and a placement cavity 8. Connection frame 9, external pad cavity 10, base 11, damping spring shock absorber 12, viewing window 13, detector 14, connection belt 15, hydraulic air rod 16, limit assembly 17, connection spring 1701, positioning Board 1702, sound insulation board 1703, card slot 1704, auxiliary component 18, built-in board 1801, leakage hole 1802, installation groove 1803, auxiliary chamber 1804, built-in groove 19, connecting rod 20, the inside of the outer shell 1 is provided with a placement chamber 8, And one end outside the placement chamber 8 is equipped with a push rod 7, the outer casing 1 is provided with two groups, and a connecting belt 15 is bonded and connected betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com