Manufacturing method of high-precision outer-hexagonal inner-circle special-shaped section seamless tube for nuclear power

A technology of special-shaped section and manufacturing method, which is applied in the field of high-precision outer hexagonal inner circular special-shaped section seamless pipe and its manufacturing field, can solve the problems of less deformation, affecting dimensional accuracy, unusable control of size and dimensional accuracy, etc. Product performance, the effect of meeting technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in further detail below according to the accompanying drawings and examples of implementation.

[0062] The directional terms such as up, down, left, right, front, back, front, back, top, and bottom that are mentioned or may be mentioned in this specification are defined relative to the structures shown in the drawings. The words " "Inside" and "outside" respectively refer to the direction toward or away from the geometric center of a specific component. They are relative concepts, so they may change accordingly according to their different positions and different usage states. Accordingly, these or other directional terms should not be construed as limiting terms.

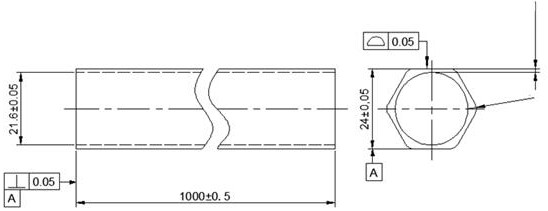

[0063] Such as figure 1 As shown, high-precision outer hexagonal inner circle special-shaped cross-section seamless pipe for nuclear power, outer edge distance D1=24.0mm, deviation ±0.05mm; inner circle diameter d1=21.6mm, deviation ±0.05mm; minimum wall thickness S1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com