Granulation system and granulation monitoring method

A technology of granulation and granulation machine, which is applied in the field of powder granulation, can solve the problem of high difficulty in control, achieve the effect of improving granulation quality, improving automation and intelligence, and stabilizing the granulation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

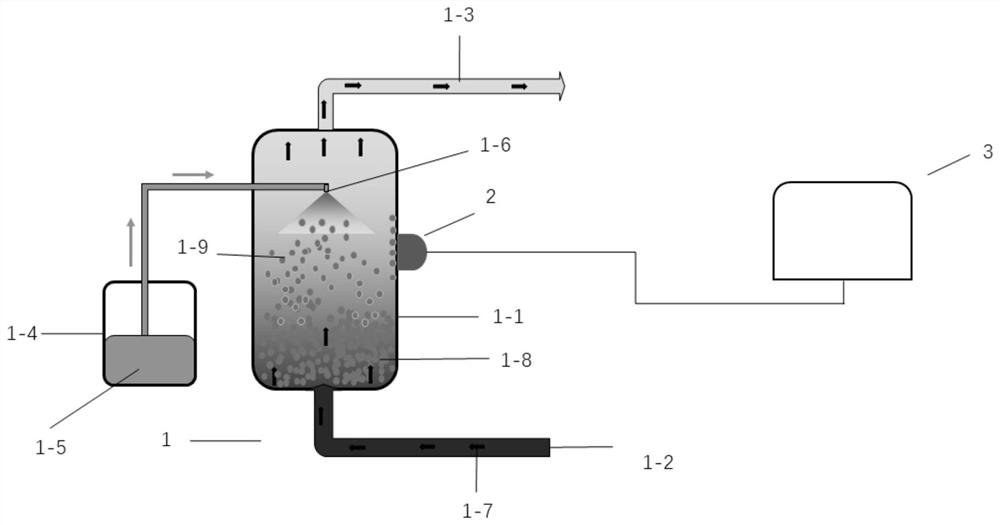

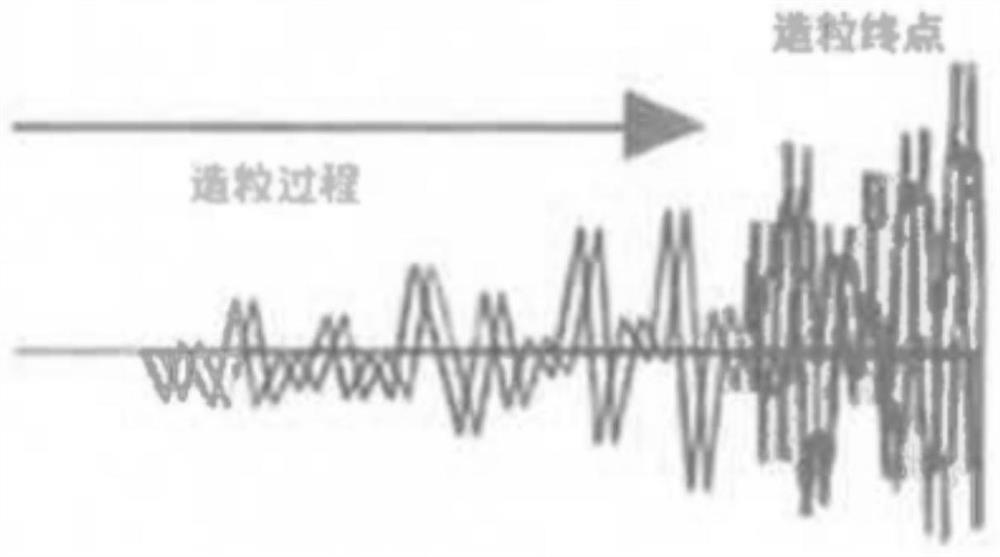

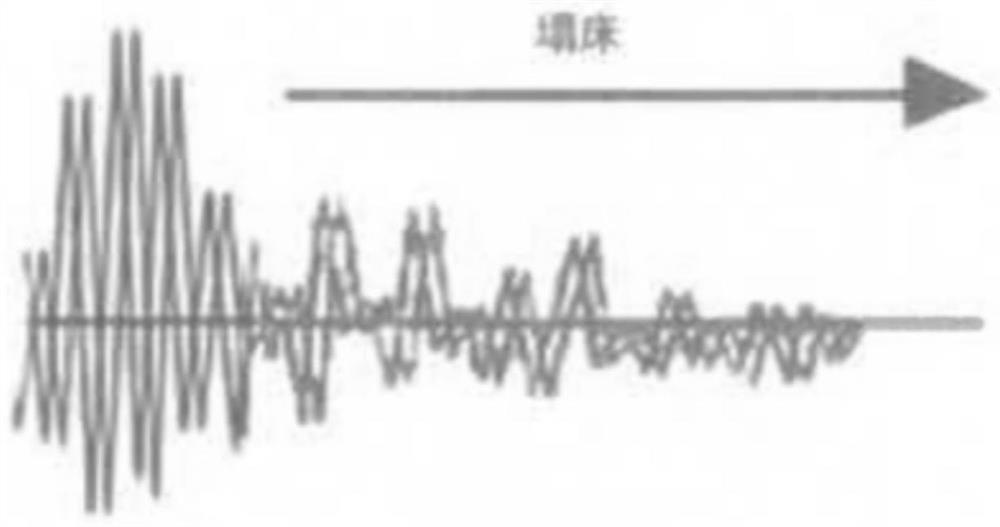

[0023] The inventors of the present application found that during the boiling granulation process, as the raw material powder particles in the fluidized state aggregated larger, the sound waves emitted by them changed, and the collected sound waves were converted into image signals by an oscilloscope Finally, according to the change of the image signal, it can reflect the change of the particles during the granulation process, so that the whole granulation process can be visualized, the automation and intelligence of the granulation can be improved, the granulation process can be stabilized, and the granulation quality can be improved.

[0024] Various exemplary embodiments of the present disclosure are described in detail below with reference to the accompanying drawings. It should be noted that relative arrangements of components and steps, numerical expressions and numerical values set forth in these embodiments do not limit the scope of the present disclosure unless speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com