A kind of plant extract combined dressing based on ginseng extract and preparation method thereof

A plant extract, ginseng extraction technology, applied in bandages, absorbent pads, medical science and other directions, can solve the problems of poor air permeability, reduce the air permeability of chitosan film, wound healing effects, etc., achieve good stability, no side effects sterilization Excellent efficacy, antibacterial and bacteriostatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

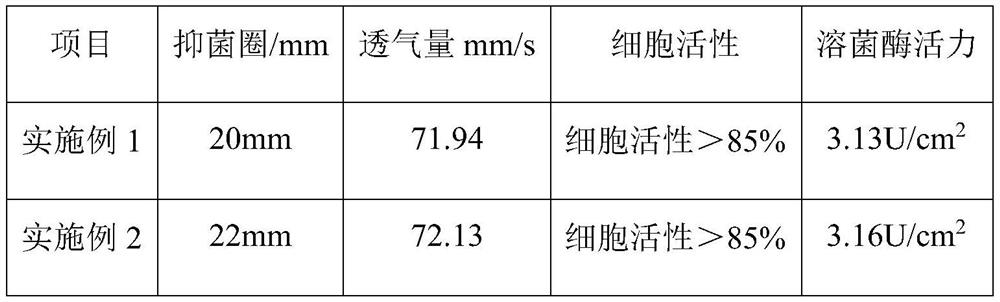

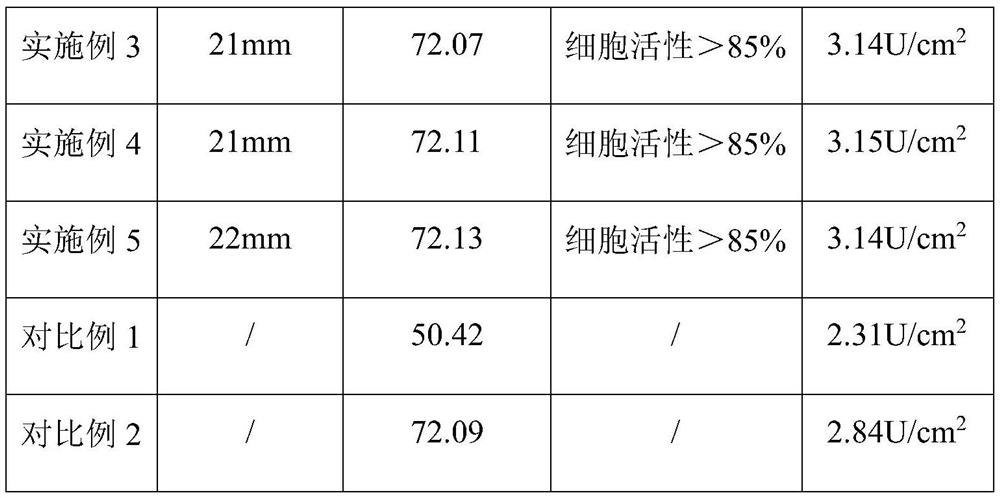

Examples

Embodiment 1

[0041] A preparation method of a plant extract combination dressing based on ginseng extract, comprising the following steps:

[0042] (1) get zinc nitrate hexahydrate and ethanol, mix and stir for 20min, add ethyl orthosilicate, stir to obtain material C;

[0043] Take cetyltrimethylammonium bromide and deionized water, mix and stir for 5 minutes, add ether, ethanol and ammonia water, continue stirring for 30 minutes, slowly add material C and 3-mercaptopropyltrimethoxysilane dropwise, and stir for 4 hours , the product was collected by centrifugation, washed with ethanol and deionized water in turn, and dried under vacuum at 60 °C; after drying, it was transferred to a mixed solution of ethanol and hydrochloric acid, refluxed for 24 h at 68 °C, washed and dried to obtain mesoporous silica.

[0044] Take mesoporous silica and N,N-dimethylformamide, disperse by ultrasonic for 10min, get material B; take KH-550, succinic anhydride and N,N-dimethylformamide, disperse by ultrason...

Embodiment 2

[0053] A preparation method of a plant extract combination dressing based on ginseng extract, comprising the following steps:

[0054] (1) get zinc nitrate hexahydrate and ethanol, mix and stir for 25min, add ethyl orthosilicate, stir to obtain material C;

[0055] Take cetyltrimethylammonium bromide and deionized water, mix and stir for 8min, add ether, ethanol and ammonia water, continue to stir for 35min, slowly add material C and 3-mercaptopropyltrimethoxysilane dropwise, and stir for 5h , the product was collected by centrifugation, washed with ethanol and deionized water in turn, and dried in vacuum at 63 °C; after drying, it was transferred to a mixed solution of ethanol and hydrochloric acid, refluxed for 22 h at 69 °C, washed and dried to obtain mesoporous silica.

[0056] Take mesoporous silica and N,N-dimethylformamide, ultrasonically disperse for 13 minutes to obtain material B; take KH-550, succinic anhydride and N,N-dimethylformamide, ultrasonically disperse for ...

Embodiment 3

[0065] A preparation method of a plant extract combination dressing based on ginseng extract, comprising the following steps:

[0066] (1) get zinc nitrate hexahydrate and ethanol, mix and stir for 30min, add ethyl orthosilicate, stir to obtain material C;

[0067] Take cetyltrimethylammonium bromide and deionized water, mix and stir for 10min, add ether, ethanol and ammonia water, continue to stir for 40min, slowly add material C and 3-mercaptopropyltrimethoxysilane dropwise, and stir for 6h , the product was collected by centrifugation, washed with ethanol and deionized water in turn, and dried under vacuum at 65 °C; after drying, it was transferred to a mixed solution of ethanol and hydrochloric acid, refluxed for 20 h at 70 °C, washed and dried to obtain mesoporous silica.

[0068] Take mesoporous silica and N,N-dimethylformamide, ultrasonically disperse for 15 minutes to obtain material B; take KH-550, succinic anhydride and N,N-dimethylformamide, ultrasonically disperse ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com