Process for producing solid particles, solid particles and use thereof

A technology of solid particles and inorganic solids, applied in chemical instruments and methods, improvement of process efficiency, silicon compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0104] Two mineral concentrates or concentrates (inorganic solids containing at least one alkali metal and / or alkaline earth metal) derived from lithium extraction and consisting essentially of spodumene, containing a) 5.0% by mass of Li 2 O and b) 7.0% by mass of Li 2 O, the calcination and leaching process (extraction) was carried out on a laboratory scale under the following conditions:

[0105] Calcination temperature: 1100°C

[0106] Calcination time: 1h

[0107] Baking temperature: 250℃

[0108] Baking time: 1h

[0109] h 2 SO 4 / Spodumene: 0.3

[0110] Water / spodumene: 3:1

[0111] Flushing solution / spodumene: 1:1

[0112] Extraction temperature: 90°C

[0113] Extraction time: 1h

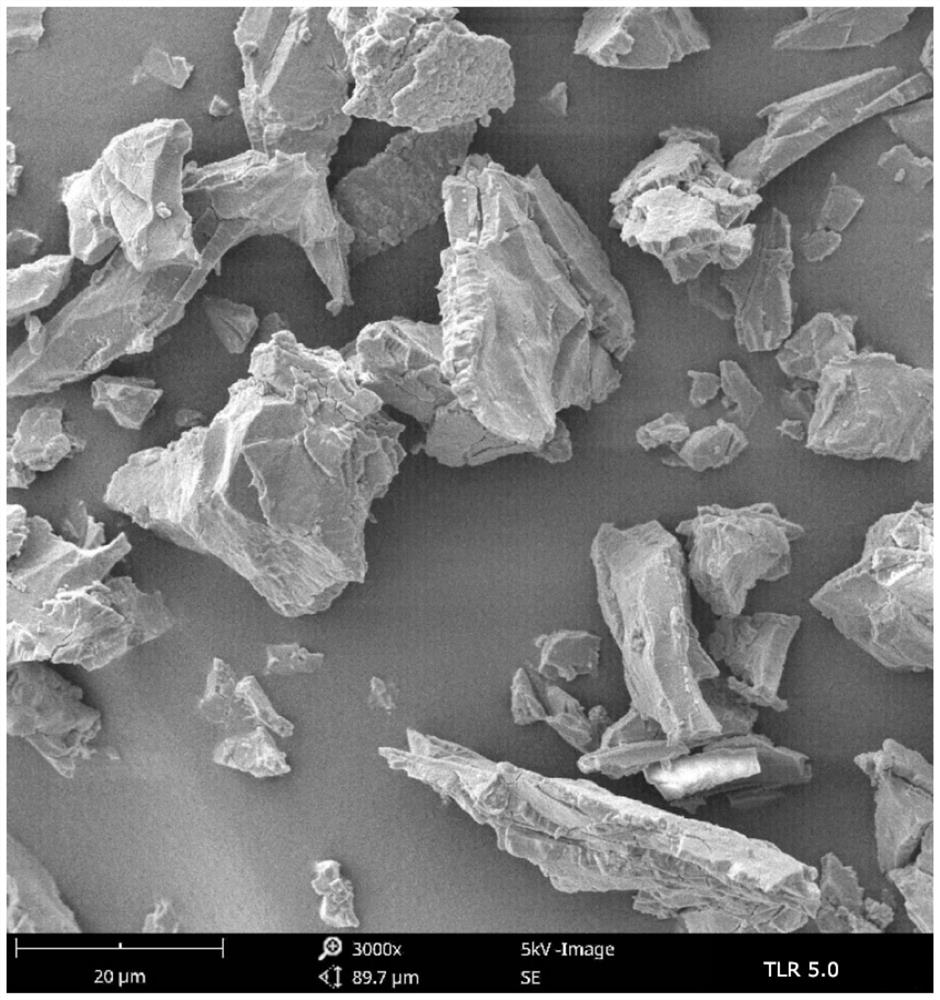

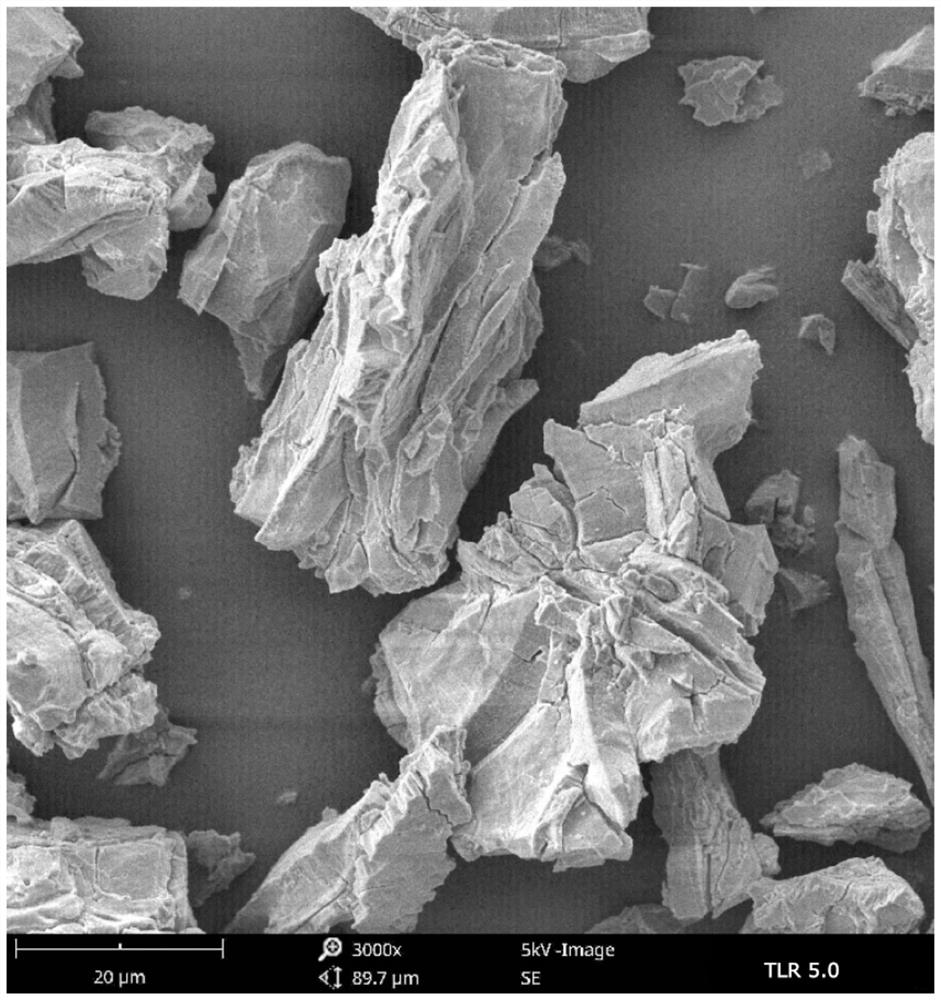

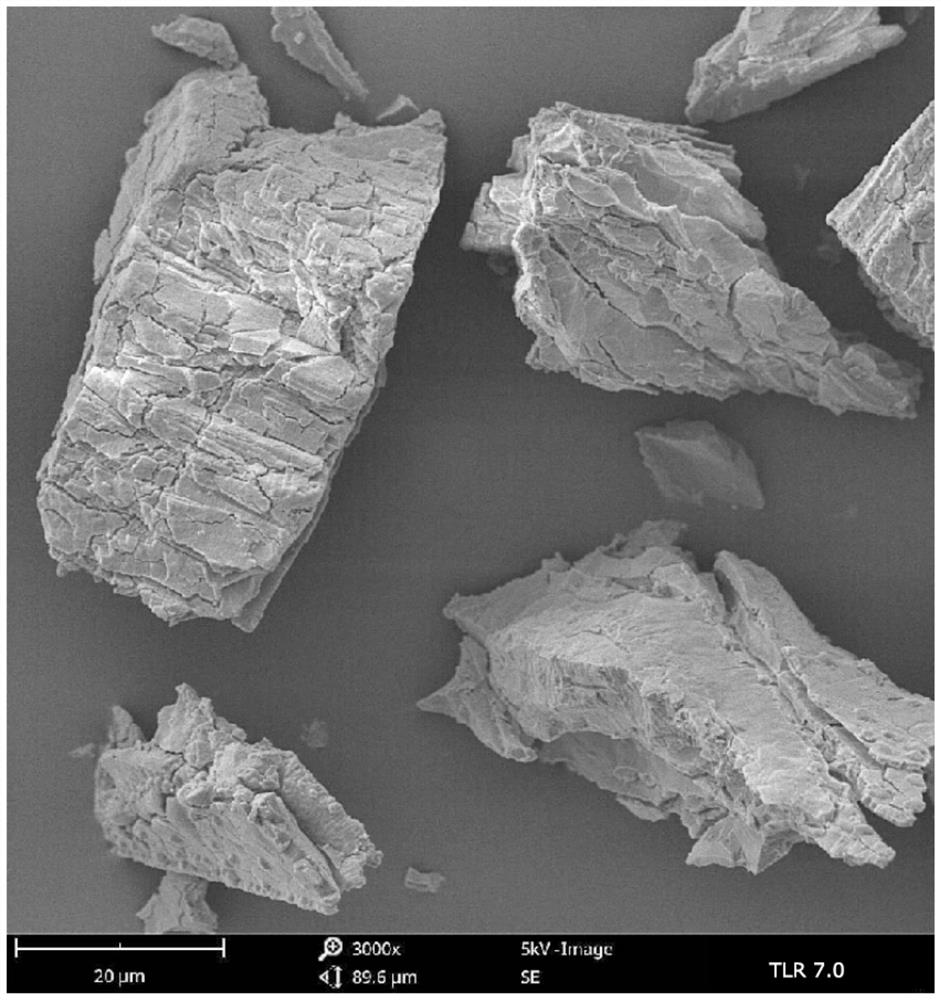

[0114] After the above-mentioned extraction or leaching, two lithium-depleted residues and thus solid particles according to the invention are obtained, hereinafter referred to as TLR 5.0 and TLR 7.0 (TLR=Test Leach Residue). The following chemical, physical and mineralogical prope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com