Composite light guide plate structure and backlight module

A light guide plate and combined technology, applied in the field of light guide plates, can solve problems such as inconvenient manufacture and installation, light blocking of light guide plates, easy to cause dirt, etc., to achieve the effects of improving assembly efficiency, reducing process flow, and reducing assembly failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

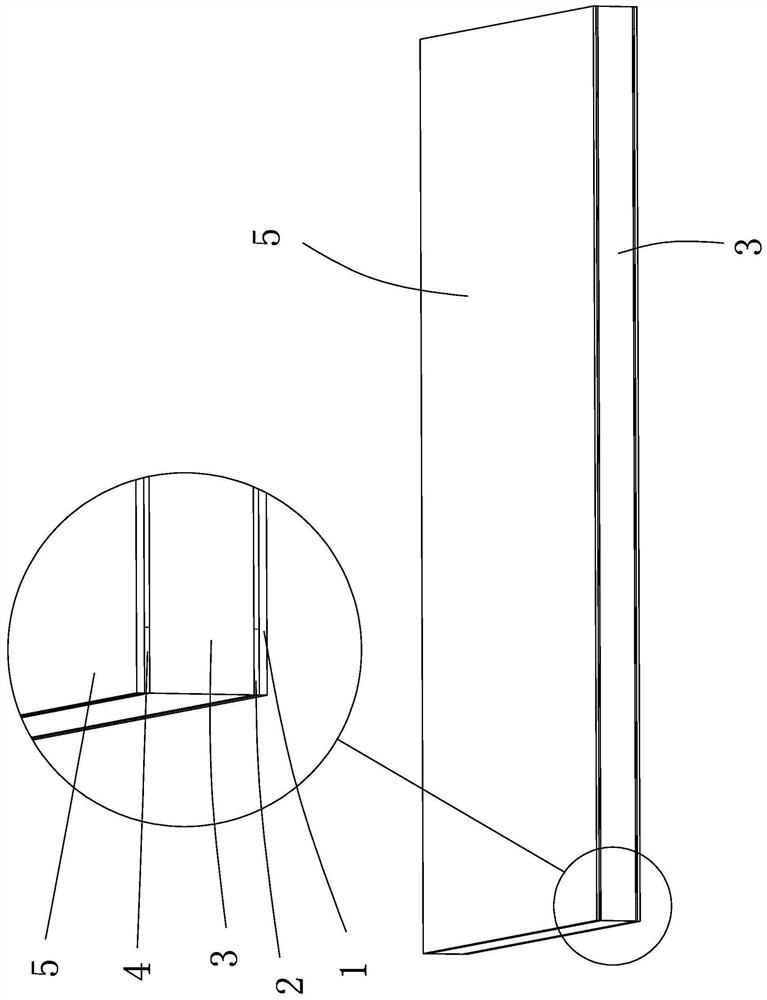

[0028] Such as Figure 1-4 As shown, a composite light guide plate structure, including from bottom to top (with figure 1 The reflective layer 1, the first adhesive layer 2, the light guide plate 3, the second adhesive layer 4 and the optical film layer 5 are arranged in sequence, the dots of the light guide plate 3 are arranged facing downwards, and the light-emitting surface is arranged facing upwards, and the light guide plate 3. The light incident surface is on the side. In this specific embodiment, the light guide plate 3 has a rectangular structure, but it is not limited thereto. In some embodiments, the shape of the light guide plate 3 can be set according to actual needs.

[0029] The light guide plate 3 can adopt various existing light guide plate structures, such as flat plates, wedge-shaped plates, etc., can be formed by injection molding, cutting molding, etc., and can be made of materials such as acrylic plates and PC (polycarbonate) plates. become.

[0030] Bo...

Embodiment 2

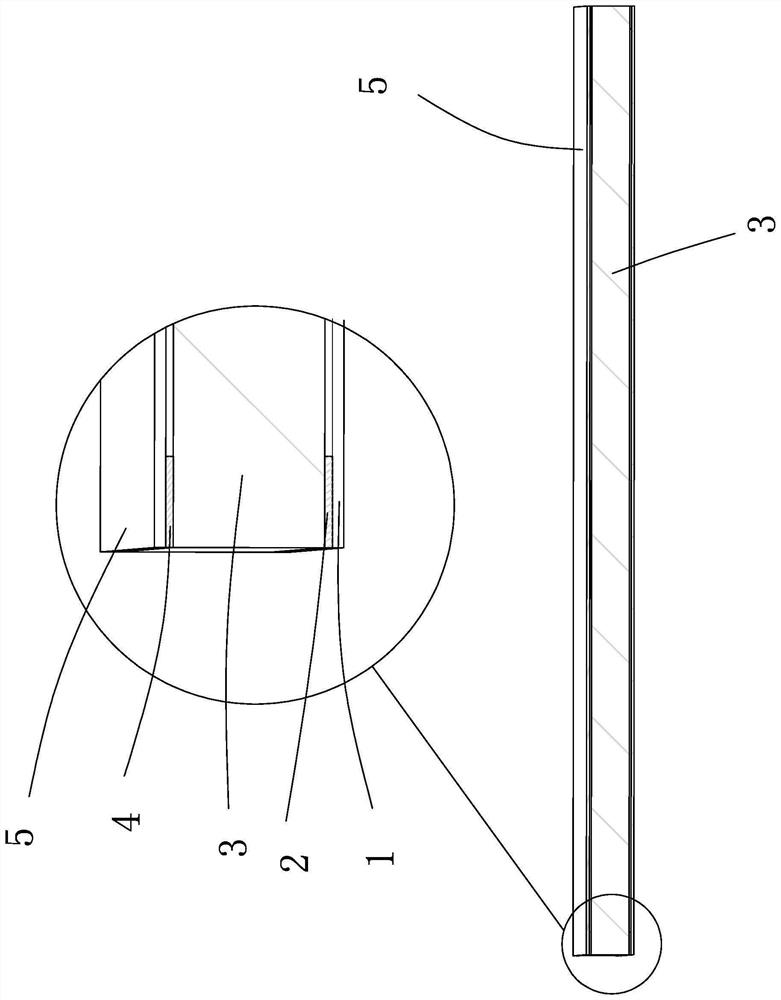

[0040] Such as Figure 6-8 As shown, the difference between this specific embodiment and Embodiment 1 is that: the optical film layer 5 of this specific embodiment is a composite film layer, and each film layer of the composite film layer is bonded and fixed by frame-shaped adhesive layers in sequence, and the adhesive layers are respectively It is arranged between the edges of each film layer, and the composite film layer is used to improve the brightening effect, and the structure is easy to realize and low in cost.

[0041] Specifically, in this embodiment, the composite film layer 5 includes a first brightness enhancement film 51, a third adhesive layer 52, a second brightness enhancement film 53, a fourth adhesive layer 54 and a diffusion layer 55, the third adhesive layer 52 and the second adhesive layer The four adhesive layers 54 are all rectangular frame structures, and the second adhesive layer 4 is arranged between the edge of the light-emitting surface of the light...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com