Plug press-in device for bats

A press-in device and plug technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as bad process, bad scratches on the bat body, affecting production efficiency, etc., and achieve a processing defect rate Low, the effect of reducing scratches and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

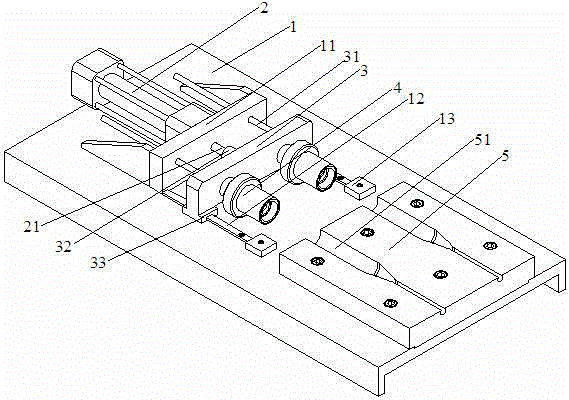

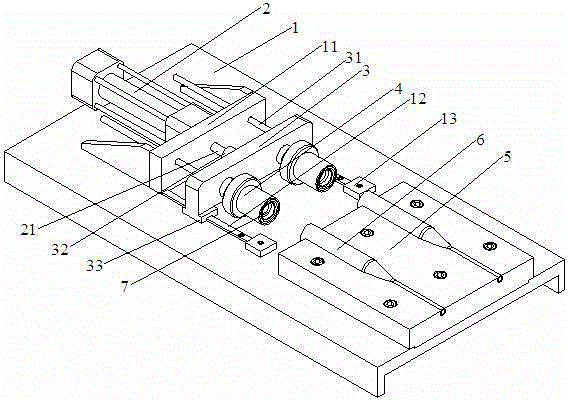

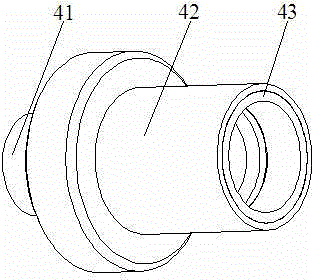

[0018] figure 1 , a plug press-in device for a ball bat, including a buckle frame body (1), a cylinder (2), a pressure plate (3), a pressure head (4) and a fixing plate (5), and the cylinder (2) is installed on the frame body On the cylinder fixing plate (11) of (1), the cylinder head (21) is connected with the pressure plate connector (32) of the pressure plate (3) through the cylinder fixing plate (11), and the cylinder fixing plate on the frame (1) (11) There is a pair of guide rails (12) in front, each guide rail (12) has a stopper (13) at the front, and two positioning rods (31) are provided at the back of the pressure plate (3) to protrude from the cylinder fixing plate (11) , two pressure heads (4) are connected to the pressure plate (3), and there is a pair of guide grooves (33) under the pressure plate (3) to match with the guide rails (12) on the frame (1), and act on the cylinder (2) Driven, the pressing plate (3) and the pressing head (4) can move on the guide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com