Preparation method of diphenolic acid antibacterial cotton fabric

A cotton fabric and bisphenolic acid technology is applied in the field of fabrics to achieve the effects of low cost, simple operation and comfortable wearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

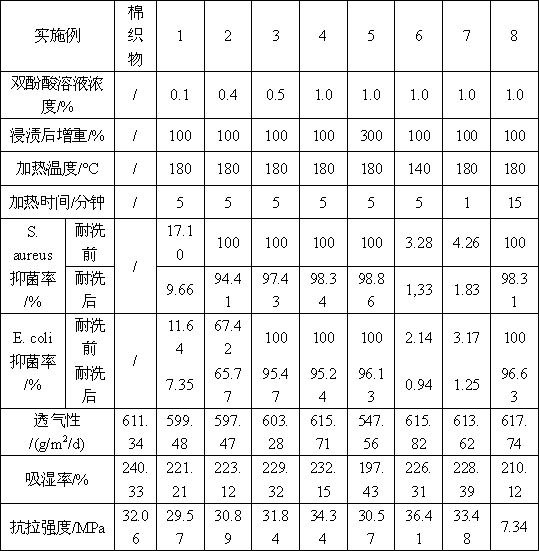

Embodiment 1

[0018] The clean cotton fabric was immersed in 0.1% bisphenolic acid ethanol solution for 30 minutes, rolled to 100% weight gain, heated at 180 °C for 5 minutes, washed with ethanol and dried.

[0019] The prepared modified cotton fabric is constructed from cotton fabric and bisphenolic acid. Through the infrared analysis of the modified cotton fabric, at 1697 cm -1 and 1525 cm -1 There are C=O stretching vibration absorption peaks and benzene ring skeleton vibration absorption peaks respectively, but they are not obvious, indicating that bisphenolic acid is grafted on the surface of cotton fibers but the amount is small. The obtained antibacterial cotton fabric had poor killing effect on Staphylococcus aureus and Escherichia coli, and the antibacterial rate was only 17.10% and 11.64%. After 30 washes, the antibacterial rate dropped below 10%. The water vapor transmission rate of cotton fabric grafted with bisphenolic acid is 599.48 g / m 2 / d, the water absorption rate is 22...

Embodiment 2

[0021] The clean cotton fabric was dipped in 0.4% bisphenolic acid ethanol solution for 30 minutes, rolled to 100% weight gain, heated at 180 °C for 5 minutes, washed with ethanol and dried.

[0022] The prepared modified cotton fabric is constructed from cotton fabric and bisphenolic acid. Through the infrared analysis of the modified cotton fabric, at 1697 cm -1 and 1525 cm -1 There are obvious C=O stretching vibration absorption peaks and benzene ring skeleton vibration absorption peaks respectively, indicating that bisphenolic acid has been successfully grafted on the surface of cotton fibers. The obtained antibacterial cotton fabric has a stronger killing effect on Escherichia coli and Staphylococcus aureus than Example 1, the bacteriostatic rate of Staphylococcus aureus is almost 100%, and the bacteriostatic rate of Escherichia coli is also increased to 67.42%. After 30 times of washing, the antibacterial rate against Staphylococcus aureus dropped to 94.41%, and the ant...

Embodiment 3

[0024] The clean cotton fabric was immersed in 0.5% bisphenolic acid ethanol solution for 30 minutes, rolled to 100% weight gain, heated at 180 °C for 5 minutes, washed with ethanol and dried.

[0025] The prepared modified cotton fabric is constructed from cotton fabric and bisphenolic acid. Through the infrared analysis of the modified cotton fabric, at 1697 cm -1 and 1525 cm -1 There are obvious C=O stretching vibration absorption peaks and benzene ring skeleton vibration absorption peaks respectively, indicating that bisphenolic acid has been successfully grafted on the surface of cotton fibers. The resulting antibacterial cotton fabric has a stronger killing effect on Escherichia coli than Example 2, and the bacteriostatic rate of Staphylococcus aureus and Escherichia coli is almost 100%. After 30 times of washing, the antibacterial rate against Staphylococcus aureus dropped to 97.43%, and the antibacterial rate against Escherichia coli dropped to 95.47%. The moisture v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com