Preparation device and preparation method of auxetic composite yarn

A preparation device and composite yarn technology, applied in the direction of yarn, spinning machine, continuous winding spinning machine, etc., can solve the problem that the preparation method is not suitable for continuous production, unfavorable for the popularization and application of auxetic composite yarn, and has no preparation efficiency, etc. problems, to achieve the effect of improving the slippage phenomenon, covering effect and yarn quality, and the spinning method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

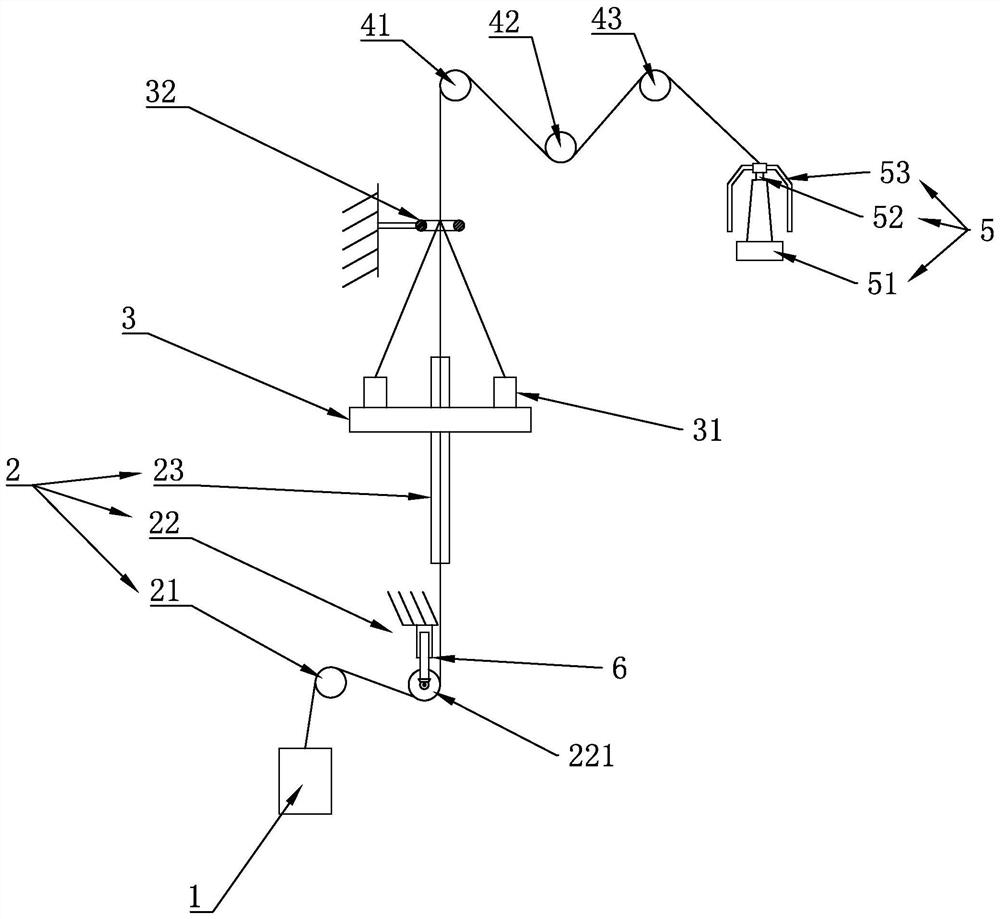

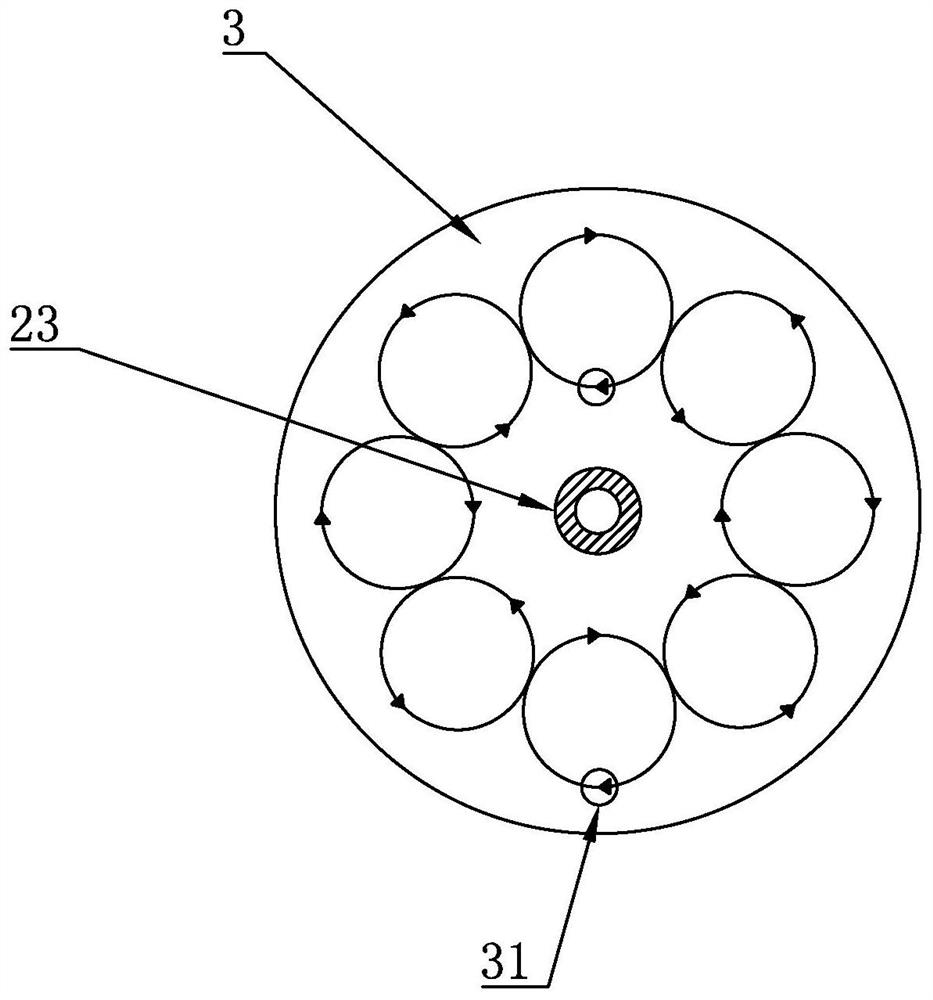

[0032] Such as figure 1 , figure 2 As shown, the embodiment of the present application provides a preparation device for auxetic composite yarn, including: a frame, the frame is hinged with a first roller 41, a second roller 42, and a third roller 43; the first yarn feeding device 1, The first yarn feeding device 1 is placed on the frame; the yarn guiding device 2, the yarn guiding device 2 is placed on the frame, and the yarn guiding device 2 includes a yarn guiding roller 21, a yarn guiding tube 23, and a tension adjustment mechanism 22; a weaving turntable 3 , the weaving turntable 3 is placed on the frame, the weaving turntable 3 is provided with some second yarn feeding devices 31, and the weaving turntable 3 is provided with a converging ring 32; the winding device 5 is placed on the frame; wherein, the guide The yarn roller 21 is placed on the side of the first yarn feeding device 1, the yarn guide tube 23 has the same axis as the knitting turntable 3 and runs through...

Embodiment 2

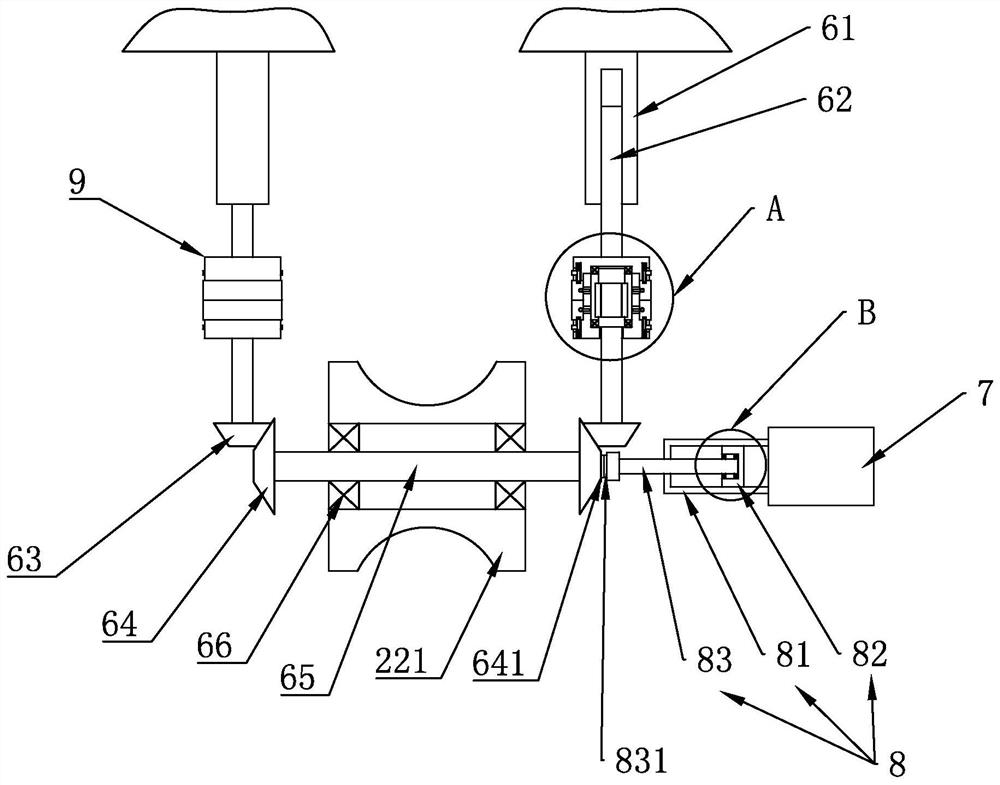

[0037] Such as figure 1 , image 3 As shown, the embodiment of the present application provides a preparation device for auxetic composite yarn. In addition to the above-mentioned technical features, further, the tension adjustment mechanism 22 includes: a tension disc 221; an adjustment device 6, and the adjustment device 6 is placed on the tension disc 221 On both sides, the adjustment device 6 includes an adjustment seat 61 fixedly connected to the frame, an adjustment rod 62 threadedly connected with the adjustment seat 61, a first bevel tooth 63 placed at one end of the adjustment rod 62, and a first bevel tooth 63 meshing with the first bevel tooth 63. Two bevel teeth 64; clutch mechanism 9, clutch mechanism 9 comprises housing 91, sleeve 92 placed in housing 91, clutch 93 placed on housing 91, clutch mechanism 9 is placed on the adjusting rod 62 and will be adjusted The rod 62 is divided into two sections, one section is connected with the housing 91, and the other sec...

Embodiment 3

[0040] Such as Figure 4 , Figure 6 As shown, the embodiment of the present application provides a preparation device for auxetic composite yarn. In addition to the above-mentioned technical features, further, the clutch 93 includes: a swivel body 931, and the swivel body 931 is provided with two Above: movable block 933, the movable block 933 is evenly distributed on the housing 91, the movable block 933 is provided with a ball head 9331, and the movable block 933 is provided with a limit part 9332; the pawl 932, the pawl 932 is connected to the movable block 933 through a rotating shaft , the pawls 932 on the same swivel body 931 are facing the same direction, and the pawls 932 on the two swivel bodies 931 are facing oppositely, and the pawls 932 are limited by the limiting part 9332 to only rotate in the direction of the pawl 932; the first Return spring 934, the first return spring 934 is placed between the ratchet 932 and the movable block 933; locking structure 95, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com