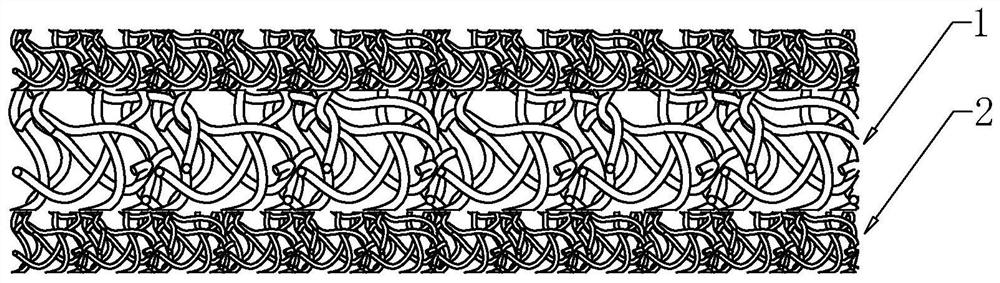

A kind of durable antibacterial cushion core and its manufacturing method

A durable and good technology, applied in the field of mats, can solve the problems of easy breeding of bacteria, low durability, instability, etc., to reduce bacterial growth, improve antibacterial durability, improve antibacterial durability and heat resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0053] Preparation of antibacterial metal carrier:

[0054] 1000g of silica sol was put into the reaction flask, heated to 50°C and stirred, then nitric acid solution was added dropwise to adjust the pH to 6, then 600g of zinc nitrate solution was added dropwise while stirring, after 1 hour of dropwise addition, continued stirring for 1 hour to obtain mixing Then put the mixed glue into a vacuum drying box to dry for 8 hours, and the drying temperature is 60 °C. After drying, the mixed glue is dried into a solid, and then the solid is ground to a powder with a particle size of 2~5 μm, and the powder is washed with ethanol. Dry in a vacuum drying oven for 1 hour at a drying temperature of 50° C. to obtain an antibacterial metal carrier.

[0055] The SiO2 content of the silica sol is 40%, the mass fraction of the nitric acid solution is 20%, and the concentration of the zinc nitrate solution is 0.5mol / L.

preparation example 2

[0057] Preparation of antibacterial metal carrier:

[0058] The difference between this preparation example and preparation example 1 is that the same amount of silver nitrate solution is used to replace the zinc nitrate solution.

preparation example 3

[0060] Preparation of antibacterial metal carrier:

[0061] The difference between this preparation example and preparation example 1 is that the same amount of copper nitrate solution is used to replace the zinc nitrate solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com